Inconel X-750 is a precipitation-hardenable nickel-chromium alloy known for its excellent strength and resistance to corrosion and oxidation at high temperatures. It is widely used in aerospace, nuclear reactors, heat-treating equipment, and gas turbines. Choosing a reliable Inconel X-750 supplier is critical for ensuring quality, performance, and cost-effectiveness. This article explores how to select trusted Inconel X-750 suppliers, compare global sources, analyze supply forms, and understand material certifications.

What Is Inconel X-750?

Inconel X-750 is designated as UNS N07750 and Werkstoff Nr. 2.4669. It maintains high mechanical strength at temperatures up to 704°C (1300°F) and offers excellent fatigue and stress rupture resistance. The alloy is primarily composed of nickel and chromium, with additions of titanium and aluminum for precipitation hardening.

Typical Chemical Composition of Inconel X-750

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 70.0 min |

| Chromium (Cr) | 14.0 – 17.0 |

| Iron (Fe) | 5.0 – 9.0 |

| Titanium (Ti) | 2.25 – 2.75 |

| Aluminum (Al) | 0.4 – 1.0 |

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 0.5 max |

Available Product Forms from Suppliers

Reputable Inconel X-750 suppliers offer various product forms depending on application and processing requirements. Common forms include:

| Form | Specifications | Typical Applications |

|---|---|---|

| Wire | ASTM B637 | Springs, fasteners, sealing rings |

| Sheet / Plate | AMS 5542, AMS 5598 | Gas turbines, aerospace parts |

| Bar / Rod | AMS 5667, ASTM B637 | Bolts, shafts, support structures |

| Tubing | Custom specs | Nuclear reactor components |

| Forgings | AMS 5667 | High-temperature parts, discs |

Top Global Inconel X-750 Suppliers

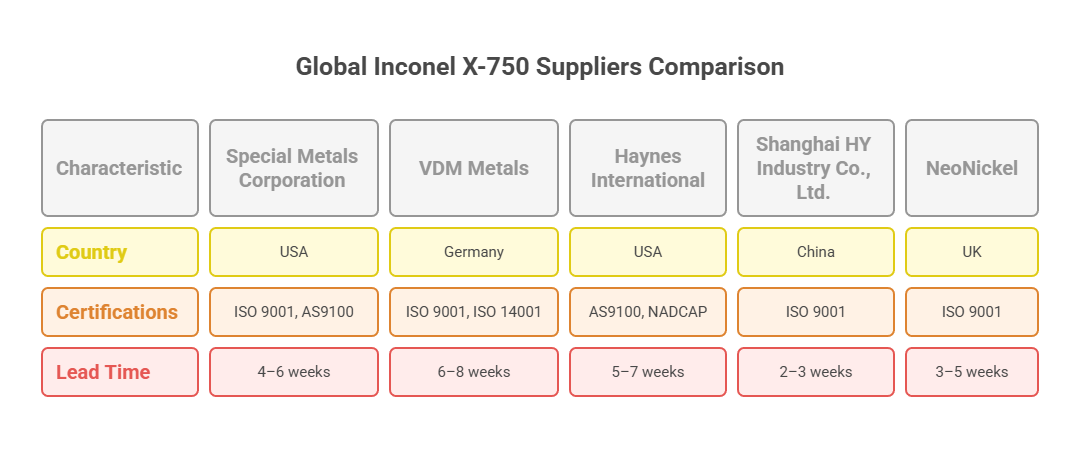

Choosing a supplier often depends on delivery time, quality control, and certifications. Below is a comparison of some well-known global suppliers:

| Supplier | Country | Certifications | Lead Time |

|---|---|---|---|

| Special Metals Corporation | USA | ISO 9001, AS9100 | 4–6 weeks |

| VDM Metals | Germany | ISO 9001, ISO 14001 | 6–8 weeks |

| Haynes International | USA | AS9100, NADCAP | 5–7 weeks |

| Shanghai HY Industry Co., Ltd. | China | ISO 9001 | 2–3 weeks |

| NeoNickel | UK | ISO 9001 | 3–5 weeks |

How to Evaluate a Supplier’s Reliability

1. Certifications: Ensure the supplier holds ISO 9001 and, if aerospace parts are involved, AS9100 certification.

2. Traceability: Full traceability from raw materials to finished product is essential for safety-critical applications.

3. Testing and Inspection: Verify whether the supplier provides third-party test reports, PMI (Positive Material Identification), and heat treatment reports.

4. Stock Availability: Some suppliers maintain ready-to-ship inventory, reducing delivery lead time.

5. Export Experience: For international buyers, suppliers with strong export records and multilingual customer service are preferred.

Heat Treatment and Mechanical Properties

Inconel X-750 is often supplied in solution-annealed or age-hardened condition. The mechanical properties vary based on heat treatment process. Below are typical values:

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Solution Annealed | 965 | 550 | 25 |

| Age Hardened | 1310 | 1100 | 20 |

Industries Served by Inconel X-750 Suppliers

Suppliers of Inconel X-750 serve a wide range of high-stakes industries, including:

Aerospace: Jet engine components, turbine blades

Nuclear: Reactor cores, control rod mechanisms

Automotive: High-temperature springs and exhaust valves

Oil & Gas: Sealing rings, downhole tools, wellhead parts

Pricing Factors and MOQ (Minimum Order Quantity)

The price of Inconel X-750 depends on several factors:

1. Product Form: Wire is typically cheaper than bar or plate.

2. Quantity: Bulk orders often enjoy discounted rates.

3. Origin: Material sourced from the USA or Europe may be more expensive but offers stricter quality assurance.

4. Customization: Heat treatment, special sizes, and third-party testing increase the cost.

Material Certifications to Request from Suppliers

When sourcing Inconel X-750, always ask for the following certifications:

• Mill Test Certificate (EN 10204 3.1 or 3.2)

• Heat Treatment Report

• Chemical Composition Report

• Mechanical Properties Report

• NDT (Ultrasonic or Radiographic) if applicable

Related Questions

What is Inconel X-750 used for?

It is widely used in aerospace engines, nuclear reactors, gas turbines, and high-temperature springs due to its excellent strength and oxidation resistance at elevated temperatures.

What forms does Inconel X-750 come in?

Common forms include wire, rod, bar, plate, sheet, forgings, and custom parts like machined components. Suppliers offer various sizes according to ASTM or AMS standards.

Which suppliers offer short lead times for Inconel X-750?

Suppliers like Shanghai HY Industry and NeoNickel are known for maintaining stock and offering 2–5 week delivery windows. Lead times can vary depending on quantity and form.