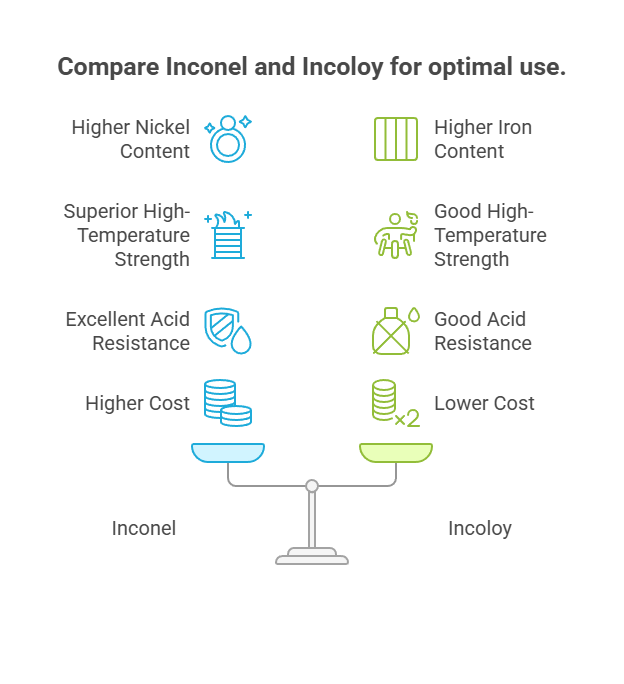

Inconel and Incoloy are both high-performance alloys made by Special Metals Corporation, designed for use in extreme environments involving heat, corrosion, and pressure. While they are often used in similar industries, they are not the same. The key difference lies in their chemical composition and performance characteristics. Inconel is primarily a nickel-chromium alloy, while Incoloy is a nickel-iron-chromium alloy. This results in different applications, strengths, and corrosion resistance profiles.

Chemical Composition Differences

One of the most important differences between Inconel and Incoloy lies in their base metals.

| Alloy | Main Elements | Nickel Content | Iron Content |

|---|---|---|---|

| Inconel (e.g., 600, 625) | Nickel, Chromium, Molybdenum | > 70% | Low |

| Incoloy (e.g., 800, 825) | Nickel, Iron, Chromium | 30–46% | High |

Corrosion Resistance Comparison

Both alloys offer excellent resistance to oxidation and corrosion, but they perform differently in specific conditions.

| Property | Inconel | Incoloy |

|---|---|---|

| High-Temperature Strength | Superior (up to 1000°C+) | Good (up to 850°C) |

| Acid Resistance | Excellent against strong acids (HCl, H2SO4) | Good, especially in phosphoric and nitric acids |

| Seawater Corrosion | Very high resistance | Moderate resistance |

| Oxidizing/Reducing Media | Performs well in both | Performs better in oxidizing conditions |

Common Applications

Each alloy has its own niche depending on the mechanical and corrosion resistance requirements.

| Application | Preferred Alloy |

|---|---|

| Jet engines and gas turbines | Inconel |

| Heat exchangers and petrochemical piping | Incoloy |

| Nuclear reactor components | Inconel |

| Furnace hardware and radiant tubes | Incoloy |

Cost Comparison

Inconel is generally more expensive due to its higher nickel content and superior high-temperature strength.

| Alloy | Approximate Price (USD/kg, 2025) |

|---|---|

| Inconel 625 | $80 – $95 |

| Incoloy 825 | $45 – $60 |

Related Questions

Can Inconel and Incoloy be used interchangeably?

Not always. While both are corrosion-resistant, Inconel performs better in extremely high temperatures and harsh acidic environments, making it more suitable for aerospace or deep-sea conditions.

Which is more expensive: Incoloy or Inconel?

Inconel is generally more expensive due to its higher nickel content and enhanced high-temperature properties.

What industries use Inconel and Incoloy?

Inconel is used in aerospace, nuclear, and marine applications; Incoloy is common in power plants, heat treatment, and chemical processing industries.