Nimonic is a family of nickel-based superalloys developed primarily for use in high-temperature, high-stress environments such as gas turbines, jet engines, and heat-resistant fasteners. One frequently asked question is whether Nimonic alloys are magnetic. This article examines the magnetic characteristics of Nimonic, including specific grades like Nimonic 75 and Nimonic 80A, and explains the metallurgical reasons behind their magnetic or non-magnetic behavior.

Magnetic Nature of Nimonic Alloys

Most Nimonic alloys are considered **non-magnetic** under normal conditions. This is due to their high nickel content and a face-centered cubic (FCC) crystal structure, which does not support ferromagnetism. However, certain grades and processing conditions may introduce weak magnetic properties.

Magnetism of Common Nimonic Grades

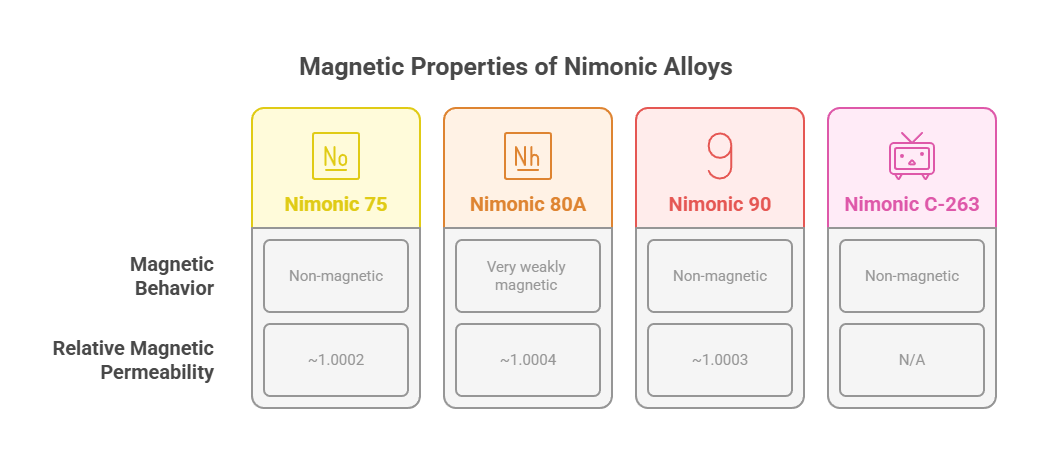

The table below shows the magnetic characteristics of popular Nimonic grades:

| Nimonic Grade | Magnetic Behavior | Explanation |

|---|---|---|

| Nimonic 75 | Non-magnetic | High Ni and Cr content; FCC structure |

| Nimonic 80A | Very weakly magnetic (if any) | Some phases may introduce trace magnetism after aging |

| Nimonic 90 | Non-magnetic | Fully austenitic; magnetic permeability near 1 |

| Nimonic C-263 | Non-magnetic | Used in aerospace; remains stable under heat |

Why Is Nimonic Generally Non-Magnetic?

The key reason lies in the alloy’s **FCC (face-centered cubic)** austenitic structure, which is typical in nickel-based alloys. Nickel itself is ferromagnetic in pure form, but in Nimonic compositions, it is combined with chromium, titanium, aluminum, and iron in a way that suppresses magnetism.

Can Nimonic Become Magnetic After Processing?

While most Nimonic grades are non-magnetic in annealed or solution-treated conditions, minor magnetic properties may emerge due to:

- Cold Working: Mechanical deformation can introduce martensitic structures in small amounts.

- Welding or Aging: Localized phase transformations during heat treatments may slightly alter magnetic response.

- Impurities: Trace iron or ferrite content in specific batches could lead to weak magnetism.

Magnetic Permeability of Nimonic Alloys

Magnetic permeability refers to the ability of a material to support the formation of a magnetic field. For Nimonic alloys, the relative magnetic permeability is typically close to 1.0, indicating negligible magnetic influence.

| Alloy | Relative Magnetic Permeability (μr) | Magnetism |

|---|---|---|

| Nimonic 75 | ~1.0002 | Practically non-magnetic |

| Nimonic 80A | ~1.0004 | Very weak magnetic response possible |

| Nimonic 90 | ~1.0003 | Non-magnetic |

Applications Where Non-Magnetic Properties Matter

The non-magnetic nature of Nimonic makes it suitable for specialized applications such as:

- Medical Devices: MRI-compatible fasteners and structural components

- Aerospace Engines: Avoiding magnetic interference in avionics

- Nuclear Reactors: Radiation-resistant and magnetically neutral materials

FAQs About Nimonic Magnetic Properties

1. Is Nimonic magnetic or non-magnetic?

Nimonic is generally non-magnetic due to its austenitic structure and high nickel-chromium content. Some grades may show very weak magnetism depending on processing.

2. Can Nimonic become magnetic after heat treatment or welding?

In rare cases, minor magnetism can appear due to phase changes during welding, cold working, or aging, but it remains minimal and non-functional for magnetic applications.

3. Is Nimonic suitable for use near sensitive electronic or magnetic equipment?

Yes, its low magnetic permeability makes it ideal for environments where magnetic interference must be avoided, such as MRI rooms or precision sensors.