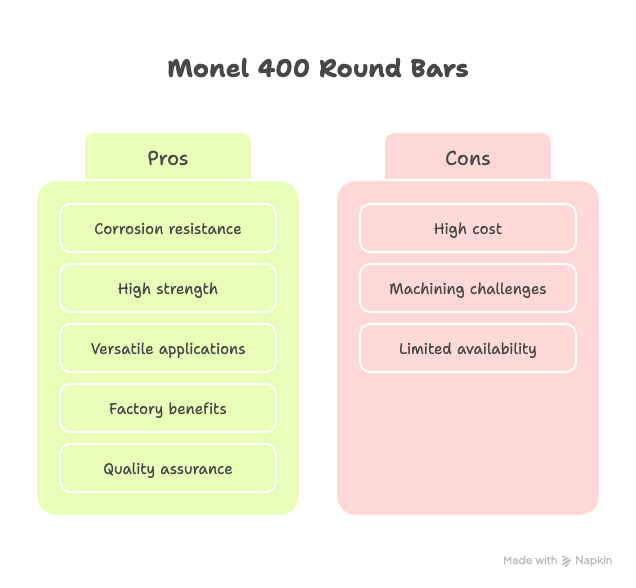

Monel 400 alloy nickel alloy round bar is a widely used material known for its excellent corrosion resistance in seawater, acids, and alkalis. It is a solid-solution alloy primarily composed of nickel and copper, making it both strong and ductile across a wide temperature range. When sourced directly from a factory, Monel 400 round bars are available at competitive prices with guaranteed quality standards such as ASTM B164 and ASME SB164. These bars are supplied in forged, rolled, and cold-drawn conditions, ensuring adaptability to diverse industrial applications.

Chemical Composition of Monel 400 Round Bar

The alloy composition of Monel 400 ensures superior resistance to corrosion and stress cracking. Below is the typical chemical makeup:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 63.0 min |

| Copper (Cu) | 28.0 – 34.0 |

| Iron (Fe) | 2.5 max |

| Manganese (Mn) | 2.0 max |

| Carbon (C) | 0.30 max |

| Silicon (Si) | 0.50 max |

| Sulfur (S) | 0.024 max |

Mechanical Properties of Monel 400 Round Bar

Monel 400 round bars deliver high strength and toughness even at sub-zero and elevated temperatures. Key mechanical properties are as follows:

| Property | Value |

|---|---|

| Tensile Strength | 550 MPa min |

| Yield Strength (0.2% offset) | 240 MPa min |

| Elongation | 35% min |

| Hardness (Rockwell B) | 65 max |

| Density | 8.80 g/cm³ |

| Melting Point | 1300 – 1350°C |

Applications of Monel 400 Alloy Round Bars

Factories supply Monel 400 round bars for industries that demand durability and corrosion resistance. Common uses include:

| Industry | Applications |

|---|---|

| Marine | Pump shafts, seawater valves, offshore structures |

| Chemical Processing | Heat exchangers, evaporators, chemical piping |

| Oil & Gas | Refinery equipment, storage tanks, downhole tools |

| Aerospace | Fuel tanks, fasteners, exhaust systems |

| Power Generation | Turbine components, steam generator parts |

Factory Supply Advantages

Purchasing Monel 400 round bars directly from a factory provides benefits including:

- Direct factory pricing with no middleman costs

- Customized dimensions and surface finishes (bright, black, polished)

- Strict quality control with mill test certificates

- Bulk order capacity for large-scale projects

- Faster delivery with consistent stock availability

Comparison with Other Nickel Alloy Round Bars

Monel 400 bars are often compared with Inconel and Incoloy grades. The table below highlights the differences:

| Alloy | Main Composition | Corrosion Resistance | Strength | Cost |

|---|---|---|---|---|

| Monel 400 | Ni-Cu | Excellent in seawater & alkalis | Medium | Moderate |

| Inconel 625 | Ni-Cr-Mo-Nb | Excellent in acids & high temp | High | High |

| Incoloy 825 | Ni-Cr-Fe-Mo-Cu | Good in sulfuric & phosphoric acids | Medium | Moderate |

Related Questions and Answers

What is Monel 400 round bar used for?

Monel 400 round bar is used in marine, chemical, aerospace, and oil & gas industries for parts requiring corrosion resistance and strength in harsh environments.

Is Monel 400 more expensive than stainless steel?

Yes, Monel 400 is more expensive due to its high nickel and copper content, but it provides longer service life in seawater and chemical conditions.

Can Monel 400 round bars be machined easily?

Monel 400 has good machinability with proper tooling and techniques, though it work-hardens quickly, requiring slow speeds and rigid tooling for best results.