Monel K-500 (UNS N05500) is a precipitation-hardening nickel-copper-aluminum-titanium alloy, valued for its high strength, corrosion resistance, and durability in marine, chemical, and oil & gas environments. When purchasing directly from a mill or factory (bulk orders, standard forms: bars, plates, tubes), the “factory price” reflects the base material cost plus processing, fabrication, and minimal mark-ups. This article reviews typical 2025 factory-level price ranges, factors affecting cost, and what buyers should watch for when procuring Monel K-500.

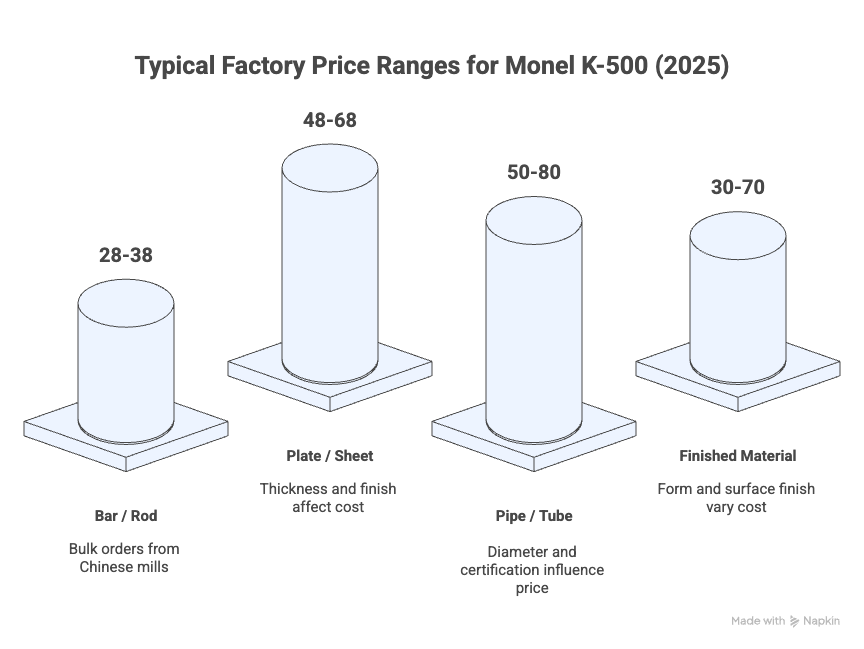

Typical Factory Price Ranges (Per kg)

Based on public supplier listings and market summaries as of 2025, typical factory or FOB-factory price ranges for Monel K-500 are:

- Bar / Rod (bulk lots, factory FOB): ~ USD 28–38/kg when ordered in large quantities (e.g. from Chinese mills for bulk supply).

- Plate / Sheet: Roughly USD 48–68/kg, depending on thickness, finish, and quantity. Thin or standard-thickness plates at lower end; thicker or small-lot plates at upper end.

- Pipe / Tube / Seamless Pipe: ~ USD 50–80/kg depending on diameter, wall-thickness, and certification requirements.

- Typical finished material (small to medium lots, standard forms): ~ USD 30–70/kg depending on form, surface finish, and required documentation.

These ranges are indicative. Actual price depends on many variables including order size, certification, form, and processing requirements.

Key Factors That Influence Monel K-500 Factory Price

The price for Monel K-500 from factories or mills depends on multiple factors:

- Raw-metal commodity prices: Because Monel K-500 contains a large fraction of nickel and copper, fluctuations in global nickel and copper markets heavily influence base cost.

- Product form and processing complexity: Bars or rods generally cost less per kg than plates, tubes, or finished/seamless components, because rolling, extrusion, or additional operations add cost.

- Order quantity / batch size: Bulk orders and full-batch volumes typically secure the lowest per-kg pricing. Small-lot orders or custom sizes tend to cost more.

- Certifications & traceability (MTC, heat treatment, test reports): Orders requiring mill test certificates, specific metallurgy specifications, or special heat treatment will have added cost.

- Surface finish and additional treatments: Polishing, bright annealing, surface finishing, or custom cutting increase production cost.

- Shipping, export paperwork, and duties (if imported): For global procurement, freight, export documentation, and customs/import duties further add to landed cost beyond base factory price.

Common Factory-Supplied Forms and Their Uses

Monel K-500 factories typically supply the following standard forms at factory pricing:

- Bars & Rods: Raw bars, round bars — used for shafts, fasteners, marine hardware.

- Plates & Sheets: For fabrication into tanks, structural components, corrosion-resistant panels.

- Tubes & Pipes (seamless or welded): Used in marine piping, seawater systems, chemical processing plants, and oil & gas.

- Strip / Wire / Forged Forms: For small parts, fasteners, springs, specialized components where high strength and corrosion resistance are needed.

What Buyers Should Know When Requesting Factory Quotes

When approaching a mill or factory for Monel K-500 supplies, buyers should:

- Specify clearly the product form (bar, plate, tube, strip), dimensions, and whether finished or raw form is needed.

- Request full documentation: mill test certificate (MTC), alloy grade (UNS N05500), heat-treatment condition, material traceability. Certification level significantly affects price.

- Clarify whether the quote is FOB factory, or includes processing, export, and shipping (which affects final landed cost significantly).

- For large orders, negotiate bulk pricing — per-kg cost may drop substantially compared to small orders.

- Compare different forms: raw bar or rod may be cheapest per kg, but additional machining or fabrication adds cost if final shape is complex.

Related Questions

What is the typical factory price per kg for Monel K-500? Typical factory (bulk) pricing ranges from about USD 28–38/kg for raw bars/rods; for plates, tubes or smaller lot finished components, price tends to be higher, roughly USD 48–70/kg depending on form, finish, and order volume.

Why does Monel K-500 cost more than common stainless steel? Because Monel K-500 contains high fractions of nickel and copper, materials that are more expensive than iron alloys — plus processing, heat treatment, and certification add extra cost.

How much price varies between forms (bar, plate, tube)? Bars/rods generally represent the lowest per-kg cost; plates, sheets, and tubes tend to cost more due to additional rolling, extrusion or welding processes, and finished/toleranced dimensions increase cost further.