A Monel K500 nickel alloy strip factory specializes in producing high-strength, corrosion-resistant strips made from the Monel K500 alloy, a nickel-copper alloy strengthened by aluminum and titanium. These strips are widely used in marine engineering, chemical processing, oil & gas components, fasteners, sensors, and high-stress industrial parts. A professional factory must maintain tight control over chemical composition, rolling precision, hardness, and mechanical properties to ensure stable performance in harsh environments.

Main Capabilities of a Monel K500 Nickel Alloy Strip Factory

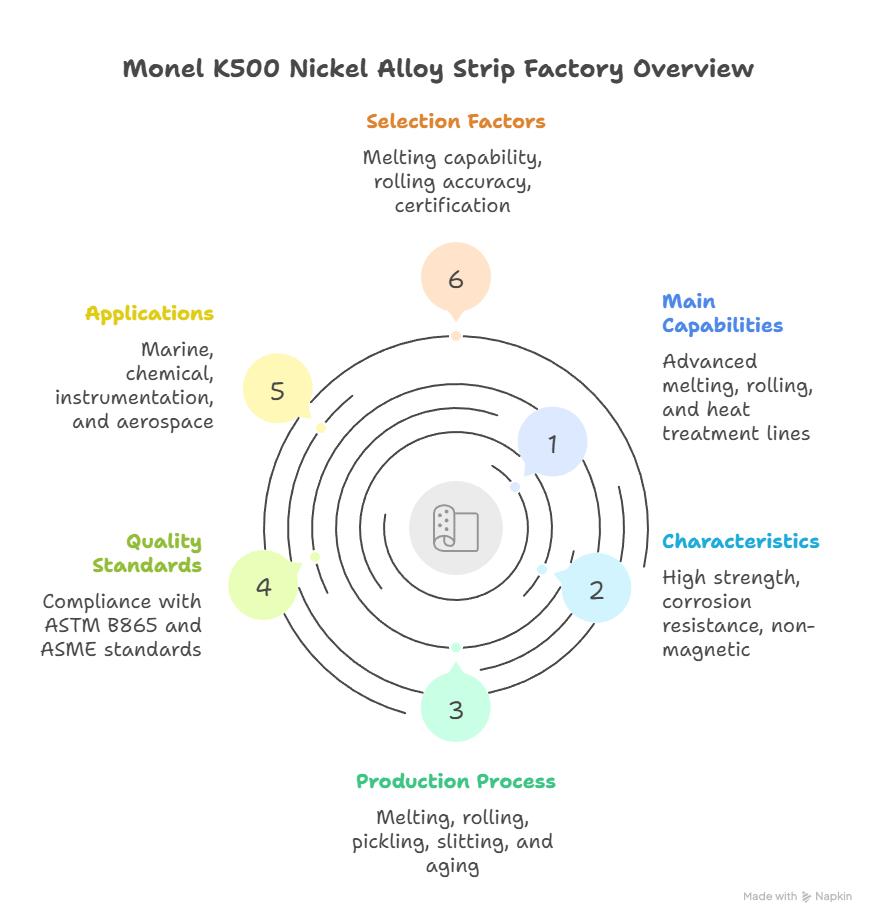

A factory producing Monel K500 strip must operate advanced melting, hot rolling, cold rolling, and heat treatment lines. Because the alloy is precipitation-hardened, factories must accurately control aging conditions to achieve the required mechanical strength and corrosion resistance.

| Capability | Description |

| Material Grade | Monel K500 (UNS N05500) |

| Thickness Range | 0.05 mm – 3.0 mm |

| Width Range | 5 mm – 600 mm |

| Mechanical Strength Control | .solution-annealed, cold-worked, precipitation-hardened states |

Characteristics of Monel K500 Alloy Used in Strip Production

Monel K500 combines the corrosion resistance of Monel 400 with higher strength and hardness due to the addition of aluminum and titanium. Factories rely on precise aging treatments to bring out these properties without compromising ductility.

| Property | Benefit |

| High Strength | Twice the strength of Monel 400 after aging |

| Excellent Corrosion Resistance | Resists seawater, acids, alkalis |

| No Chloride Stress Cracking | Suitable for high-humidity and marine environments |

| Non-magnetic | Useful for precision instruments |

Production Process in a Monel K500 Nickel Alloy Strip Factory

The manufacturing process includes alloy melting, hot rolling, pickling, cold rolling, precision slitting, and controlled aging treatment. Each stage influences the final strip performance, uniformity, and surface quality.

| Production Step | Purpose |

| Vacuum or EAF Melting | Ensures accurate chemistry and purity |

| Hot Rolling | Forms initial strip thickness |

| Cold Rolling | Achieves precise dimensions and mechanical properties |

| Heat Treatment | Controls hardening and corrosion resistance |

| Slitting & Edge Trimming | Creates uniform strips for industrial use |

Quality Standards Required for Monel K500 Strip Factories

High-end factories must meet strict international specifications such as ASTM B865 and ASME standards. Mechanical testing, surface inspection, hardness testing, and microstructure analysis ensure each batch meets industry requirements.

| Quality Test | Importance |

| Chemical Analysis | Ensures aluminum-titanium ratio for precipitation hardening |

| Tensile & Yield Strength | Critical for high-load industrial applications |

| Hardness Testing | Determines aging treatment success |

| Surface Roughness | Affects sealing, forming, and machining |

Applications for Monel K500 Nickel Alloy Strip

Monel K500 strips are used where high strength and corrosion resistance are essential. Factories supply strips for marine, chemical, instrumentation, and aerospace components requiring exceptional durability.

| Application | Requirement |

| Marine Equipment | Saltwater corrosion resistance |

| Oil & Gas Components | High strength under harsh chemical exposure |

| Precision Springs | Excellent mechanical stability |

| Sensors & Non-magnetic Parts | Stable non-magnetic properties |

How to Choose a Monel K500 Nickel Alloy Strip Factory

Buyers should evaluate the factory’s melting capability, rolling accuracy, certification level, heat-treatment expertise, and ability to provide consistent mechanical properties. High-grade applications require stable precipitation-hardening control and precise dimensional tolerances.

| Selection Factor | Reason |

| Material Certification | Ensures conformity with ASTM B865 |

| Heat Treatment Control | Directly affects alloy strength and hardness |

| Dimensional Accuracy | Important for automated processing |

| Batch Consistency | Critical for aerospace and marine components |

FAQ

1. What thicknesses do Monel K500 nickel alloy strip factories typically supply?

Most factories offer thicknesses ranging from 0.05 mm to 3.0 mm depending on the application and customer requirements.

2. Why is heat treatment important in Monel K500 strip production?

Heat treatment activates the precipitation-hardening effect, giving Monel K500 its high strength and improved mechanical performance.

3. Which industries commonly use Monel K500 nickel alloy strips?

The alloy is widely used in marine engineering, oil & gas components, chemical equipment, precision springs, sensors, and high-strength non-magnetic parts.