Monel metal is a widely used nickel-copper alloy known for its exceptional corrosion resistance, mechanical strength, and reliability in harsh environments. Understanding Monel metal prices is important for buyers, engineers, and procurement teams when sourcing material for industries such as chemical processing, oil and gas, marine engineering, and aerospace. The cost of Monel products can vary depending on the grade, product form, order quantity, and global nickel price fluctuations. Below, we break down the main factors that influence Monel metal prices and provide detailed price comparisons for different Monel grades and products.

What Affects Monel Metal Prices?

The price of Monel metal is influenced by several key factors:

1. Nickel Market Price: Since Monel is primarily composed of nickel and copper, global nickel market prices directly affect its cost.

2. Alloy Composition: Different Monel grades (such as Monel 400, Monel K500) have varied mechanical properties and chemical resistance, impacting the production cost.

3. Product Form: Sheets, plates, bars, pipes, and fittings have different processing and machining requirements.

4. Manufacturing Source: Prices may differ between mills, factories, and distributors.

5. Order Volume: Bulk purchases typically offer lower per-unit prices compared to small-quantity orders.

Monel Metal Grades and Price Differences

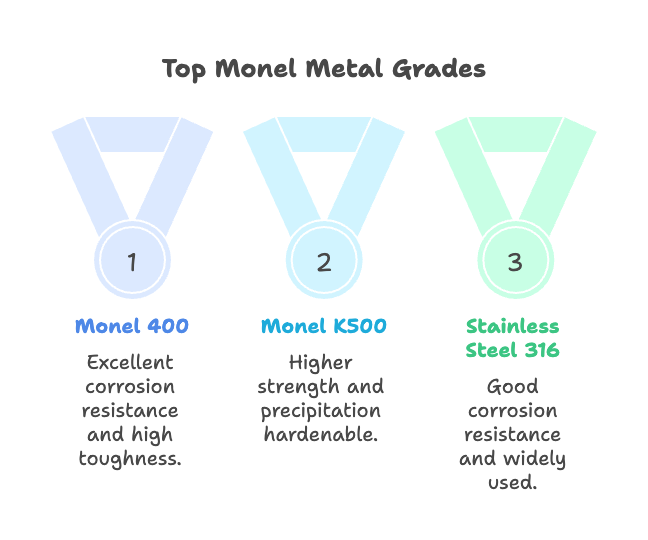

The two most common grades are Monel 400 and Monel K500. The following table shows the typical characteristics and market price tendencies:

| Grade | Composition | Key Properties | Price Range (USD/Kg) |

|---|---|---|---|

| Monel 400 | ~67% Ni, ~30% Cu | Excellent corrosion resistance, high toughness | 20 – 35 |

| Monel K500 | Ni-Cu with Al & Ti | Higher strength, precipitation hardenable | 25 – 40 |

Monel Metal Products Price Overview

Different forms of Monel metal are priced differently based on size, processing, and manufacturing complexity:

| Product Form | Common Sizes | Applications | Approx. Price (USD/Kg) |

|---|---|---|---|

| Monel 400 Sheet/Plate | 1mm – 50mm thickness | Heat exchangers, marine equipment | 20 – 30 |

| Monel 400 Round Bar | Diameter 6mm – 300mm | Pump shafts, fasteners, valves | 22 – 32 |

| Monel K500 Bar | Diameter 10mm – 200mm | Oil drilling tools, marine shafts | 28 – 38 |

| Monel 400 Pipe/Tube | OD 6mm – 600mm | Chemical processing pipelines | 24 – 34 |

| Monel Fittings | Elbows, tees, reducers | Industrial piping systems | 25 – 40 |

Global Market Trends for Monel Metal Prices

Monel prices are directly linked to nickel price trends. In recent years, nickel price volatility has created fluctuations in Monel costs. Factors such as global demand for stainless steel, geopolitical trade restrictions, and mining supply challenges all influence pricing. Buyers often monitor London Metal Exchange (LME) nickel prices as a reference for future Monel pricing strategies.

Monel Metal Price Comparison with Other Alloys

Compared with stainless steel and other nickel alloys, Monel is generally more expensive due to its higher nickel content. Below is a comparison:

| Material | Main Composition | Corrosion Resistance | Approx. Price (USD/Kg) |

|---|---|---|---|

| Stainless Steel 316 | Fe, Cr, Ni | Good | 5 – 8 |

| Inconel 625 | Ni, Cr, Mo | Excellent | 35 – 50 |

| Monel 400 | Ni, Cu | Very High | 20 – 35 |

| Monel K500 | Ni, Cu, Al, Ti | Very High + High Strength | 25 – 40 |

Buying Monel Metal at Factory Price

To secure the most competitive Monel metal prices, buyers should consider:

✔ Sourcing directly from factories instead of distributors.

✔ Ordering larger volumes to reduce per-unit cost.

✔ Comparing multiple suppliers from China, India, Europe, and the U.S.

✔ Checking for certifications such as ASTM, ASME, or DIN compliance to ensure quality consistency.

Related Questions about Monel Metal Prices

1. Is Monel more expensive than stainless steel?

Yes, Monel is significantly more expensive than stainless steel due to its high nickel content and superior corrosion resistance properties.

2. How do I get the best Monel metal price?

Buyers can get the best price by purchasing directly from manufacturers, ordering in bulk, and monitoring nickel market trends.

3. What industries commonly use Monel despite its higher price?

Industries such as marine engineering, chemical processing, oil and gas, and aerospace often choose Monel for its durability and corrosion resistance, even at higher costs.