Monel and Hastelloy are two well-known nickel-based alloy families commonly used in corrosive and demanding industrial environments. Although both materials offer excellent corrosion resistance and long service life, they are designed for different performance priorities and operating conditions. Monel alloys are nickel-copper based and excel in marine and alkaline environments, while Hastelloy alloys are nickel-chromium-molybdenum based and are specifically developed to handle highly aggressive chemical corrosion. Understanding the differences between Monel and Hastelloy helps engineers and buyers select the right alloy for chemical processing, oil and gas, marine engineering, and high-temperature applications.

Alloy Family Overview

Monel refers to a group of nickel-copper alloys, with Monel 400 and Monel K500 being the most widely used grades. These alloys typically contain around 60–70% nickel and 20–30% copper, providing excellent resistance to seawater, alkaline solutions, and certain acids.

Hastelloy is a family of high-performance nickel-based alloys containing chromium, molybdenum, and sometimes iron or tungsten. Common grades include Hastelloy C-276, C-22, and X, which are specifically engineered for extreme chemical resistance.

Chemical Composition Comparison

| Element | Monel (Typical) | Hastelloy (Typical) |

|---|---|---|

| Nickel (Ni) | 60 – 70% | Balance |

| Copper (Cu) | 20 – 30% | — |

| Chromium (Cr) | ≤ 2% | 14 – 22% |

| Molybdenum (Mo) | — | 9 – 16% |

| Iron (Fe) | ≤ 2.5% | ≤ 7% |

The copper-rich composition of Monel provides outstanding resistance to seawater corrosion, while the high chromium and molybdenum content in Hastelloy delivers superior protection against aggressive acids.

Mechanical Properties

Monel offers good strength and toughness across a wide temperature range. Grades like Monel K500 can be precipitation-hardened to achieve higher strength for structural applications.

Hastelloy generally provides higher strength at elevated temperatures and better resistance to creep and stress rupture, depending on the grade.

| Property | Monel | Hastelloy |

|---|---|---|

| Room Temperature Strength | Moderate | High |

| High-Temperature Strength | Good | Excellent |

| Work Hardening | High | High |

Corrosion Resistance

Monel performs exceptionally well in seawater, brine, hydrofluoric acid, and alkaline environments. It is widely used in marine engineering and offshore applications.

Hastelloy is designed for extreme corrosion resistance, particularly against strong acids such as sulfuric acid, hydrochloric acid, and mixed acid environments. It also resists pitting, crevice corrosion, and stress corrosion cracking.

Temperature Performance

Monel is typically used at moderate temperatures and maintains good mechanical properties at both low and moderately high temperatures.

Hastelloy alloys are capable of operating at higher temperatures, often exceeding 1000°C for certain grades, while maintaining oxidation and corrosion resistance.

Fabrication and Machinability

Monel is known to work-harden rapidly during machining, requiring proper tooling and cutting parameters. Welding is generally straightforward with appropriate filler materials.

Hastelloy is more challenging to machine due to its strength and toughness, but it offers excellent weldability and fabrication performance when proper procedures are followed.

Typical Applications

Monel Applications:

Marine hardware, seawater piping, heat exchangers, offshore oil and gas components, valves, pumps, and chemical processing equipment handling alkaline media.

Hastelloy Applications:

Chemical reactors, acid processing equipment, heat exchangers, pollution control systems, aerospace components, and high-temperature industrial equipment.

Cost Comparison

Monel is generally less expensive than Hastelloy due to its simpler composition and lower alloying content.

Hastelloy typically commands a higher price because of its superior corrosion resistance and complex alloy chemistry.

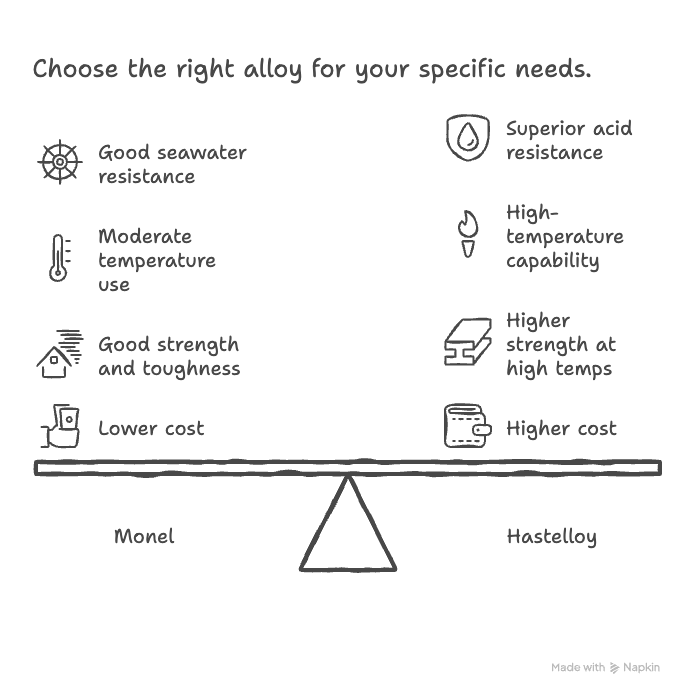

How to Choose Between Monel and Hastelloy

Choose Monel if: the application involves seawater, marine environments, or alkaline solutions with moderate mechanical requirements.

Choose Hastelloy if: the application involves highly corrosive chemical environments, strong acids, or elevated operating temperatures.

Related Questions

Is Hastelloy more corrosion resistant than Monel?

Yes, Hastelloy generally offers superior resistance to aggressive acids and mixed chemical environments.

Which alloy is better for seawater applications?

Monel is typically preferred for seawater and marine applications due to its excellent resistance to chloride corrosion.

Is Hastelloy stronger than Monel?

In most cases, Hastelloy provides higher high-temperature strength, while Monel offers sufficient strength for moderate conditions.