Monel and stainless steel are two widely used metallic materials in industrial, marine, and chemical applications. While both are known for corrosion resistance and durability, they differ significantly in chemical composition, mechanical performance, cost, and ideal service environments. Monel is a nickel-based alloy primarily alloyed with copper, whereas stainless steel is an iron-based alloy containing chromium. Understanding the differences between Monel and stainless steel is essential for selecting the right material for corrosion resistance, strength, temperature performance, and long-term reliability.

Basic Material Overview

Monel is a family of nickel-copper alloys, with Monel 400 and Monel K500 being the most common grades. It is valued for exceptional resistance to seawater, alkaline environments, and certain acids.

Stainless Steel refers to a broad group of iron-based alloys containing a minimum of approximately 10.5% chromium. Common grades include 304, 316, 321, and 347, each optimized for different corrosion and temperature conditions.

Chemical Composition Comparison

| Element | Monel (Typical) | Stainless Steel (Typical) |

|---|---|---|

| Nickel (Ni) | 60 – 70% | 8 – 12% (300 series) |

| Copper (Cu) | 20 – 30% | — |

| Chromium (Cr) | ≤ 2% | 10.5 – 20% |

| Iron (Fe) | ≤ 5% | Balance |

| Molybdenum (Mo) | — | 2 – 3% (316 grade) |

The high nickel and copper content in Monel gives it superior resistance to chloride-rich environments, while stainless steel relies on chromium to form a passive oxide layer for corrosion protection.

Mechanical Properties

Monel offers higher strength than most austenitic stainless steels and maintains toughness over a wide temperature range. Monel K500 can be precipitation hardened for even higher strength.

Stainless Steel provides good strength and ductility, with properties varying widely depending on grade. Austenitic grades offer excellent toughness, while martensitic grades provide higher hardness.

| Property | Monel | Stainless Steel |

|---|---|---|

| Tensile Strength | High | Moderate to High |

| Yield Strength | Moderate to High | Moderate |

| Work Hardening | High | Moderate |

Corrosion Resistance

Monel excels in seawater, brine, alkaline solutions, and hydrofluoric acid environments. It is highly resistant to pitting and stress corrosion cracking in chloride media.

Stainless Steel performs well in mildly corrosive environments and atmospheric exposure. Grades such as 316 stainless steel offer improved resistance to chlorides, but prolonged seawater exposure can still cause pitting.

Temperature Performance

Monel maintains mechanical strength and corrosion resistance at both subzero and moderately high temperatures, making it suitable for cryogenic and marine applications.

Stainless Steel can operate over a wide temperature range depending on grade. High-temperature stainless steels perform well in oxidizing environments but may lose strength faster than Monel under extreme conditions.

Fabrication and Machinability

Monel is more difficult to machine due to rapid work hardening and high strength. Specialized tooling and controlled cutting speeds are required.

Stainless Steel is generally easier to machine and fabricate, especially common grades like 304 and 316, making it more cost-effective for large-scale production.

Cost Comparison

Monel is significantly more expensive due to its high nickel content and specialized performance characteristics.

Stainless Steel is much more economical and widely available, making it the preferred choice when extreme corrosion resistance is not required.

Typical Applications

Monel Applications:

Marine components, seawater piping, offshore oil and gas equipment, heat exchangers, valves, pumps, and chemical processing systems handling alkaline or chloride-rich media.

Stainless Steel Applications:

Food processing equipment, architectural structures, automotive components, pressure vessels, piping systems, and general industrial applications.

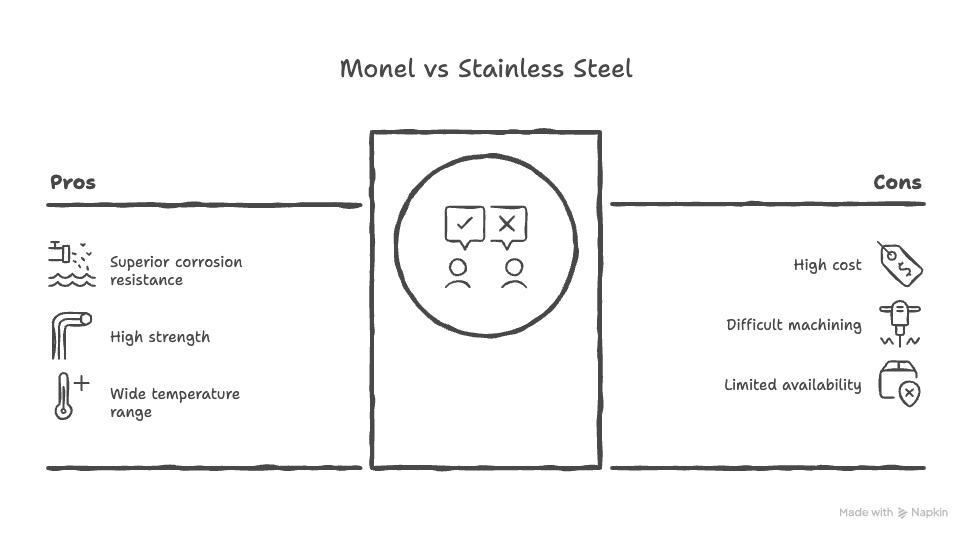

How to Choose Between Monel and Stainless Steel

Choose Monel if: the application involves seawater, marine exposure, or aggressive chloride environments requiring long-term corrosion resistance.

Choose Stainless Steel if: cost efficiency, ease of fabrication, and moderate corrosion resistance are sufficient.

Related Questions

Is Monel better than stainless steel?

Monel is superior in seawater and chloride environments, but stainless steel is more cost-effective for general applications.

Can stainless steel replace Monel?

In mild environments, stainless steel may be used, but it cannot match Monel’s performance in marine or highly corrosive conditions.

Why is Monel more expensive than stainless steel?

Monel contains a much higher percentage of nickel and copper, which significantly increases material cost.