Ni-Ti capillary tubes, also known as Nitinol capillary tubes, are precision components made from a nickel-titanium alloy known for its unique shape memory and superelastic properties. These tubes are widely used in medical devices, sensors, actuators, and aerospace applications due to their ability to recover original shape after deformation. Understanding the pricing structure of Ni-Ti tubing is essential for industries that rely on high-performance materials for demanding applications. This article provides detailed insights into Ni-Ti capillary tube pricing, influencing factors, market trends, and supplier considerations.

Overview of the Ni-Ti Capillary Tube Market

The Ni-Ti alloy market has grown significantly in recent years, primarily due to the expansion of the medical device industry, including stents, guidewires, and surgical tools. Ni-Ti’s ability to exhibit both shape memory and elasticity makes it ideal for miniaturized precision components. However, the cost of Ni-Ti capillary tubes remains higher than traditional metals such as stainless steel or pure nickel due to complex production processes and limited global manufacturing capacity.

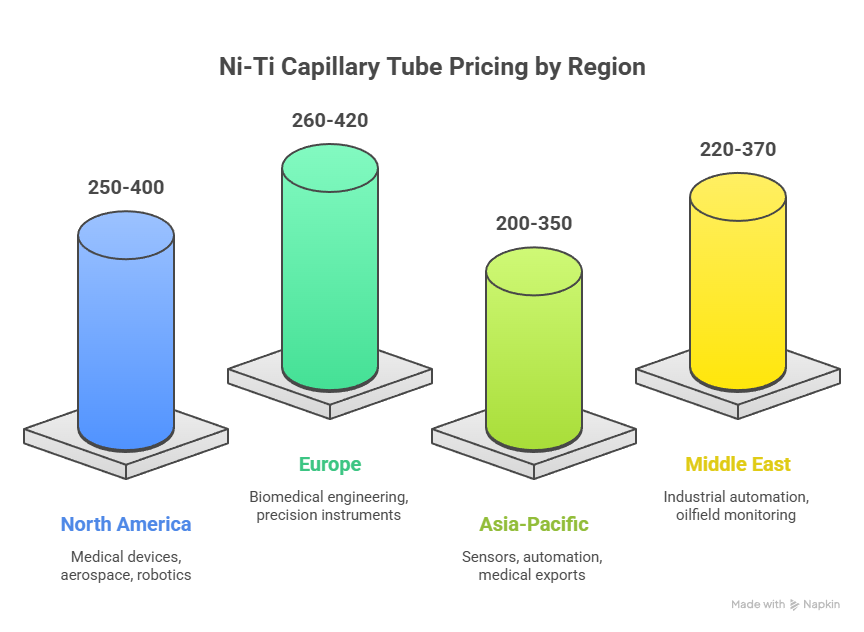

| Region | Average Price (USD/kg) | Key Applications |

|---|---|---|

| North America | 250 – 400 | Medical devices, aerospace, robotics |

| Europe | 260 – 420 | Biomedical engineering, precision instruments |

| Asia-Pacific | 200 – 350 | Sensors, automation, medical exports |

| Middle East | 220 – 370 | Industrial automation, oilfield monitoring |

Factors Influencing Ni-Ti Capillary Tube Price

Several factors contribute to the high price of Ni-Ti capillary tubes. These include material composition, processing precision, and specialized testing requirements.

| Factor | Impact on Price |

|---|---|

| Nickel-Titanium Composition Ratio | The Ni:Ti ratio (usually 55:45) must be tightly controlled; any deviation increases material waste and cost. |

| Raw Material Cost | Nickel and titanium are both premium metals, and their combined alloy increases input costs. |

| Manufacturing Method | Processes like laser cutting, vacuum annealing, and precision drawing add to manufacturing complexity. |

| Tube Diameter | Micro-capillary tubes (below 0.5 mm) cost more due to difficult handling and machining. |

| Heat Treatment | Shape memory tuning requires precise heat treatment cycles, raising production expenses. |

| Surface Finish | Electropolishing or ultra-smooth finishing enhances biocompatibility but adds cost. |

| Testing & Certification | Medical and aerospace applications demand strict ASTM and ISO testing, increasing price. |

Ni-Ti Capillary Tube Price by Size

The size of the tube directly affects pricing. Smaller inner diameters and tighter tolerance specifications result in higher production costs. The following table outlines common price ranges based on size:

| Outer Diameter (mm) | Wall Thickness (mm) | Approx. Price (USD/meter) |

|---|---|---|

| 0.3 – 0.5 | 0.05 – 0.10 | 20 – 45 |

| 0.6 – 1.0 | 0.10 – 0.20 | 18 – 35 |

| 1.1 – 2.0 | 0.20 – 0.40 | 15 – 30 |

| 2.1 – 3.0 | 0.40 – 0.60 | 12 – 25 |

| Above 3.0 | 0.60+ | 10 – 20 |

Ni-Ti Alloy Grades and Their Price Impact

Different grades of Ni-Ti alloys are used depending on the application, each with varying mechanical and thermal characteristics. The price difference reflects performance expectations and purity requirements.

| Ni-Ti Alloy Grade | Typical Composition | Approx. Price (USD/kg) | Application |

|---|---|---|---|

| Nitinol SE (Superelastic) | Ni 55.8%, Ti 44.2% | 250 – 400 | Medical guidewires, orthodontic archwires |

| Nitinol SM (Shape Memory) | Ni 55.0%, Ti 45.0% | 230 – 380 | Actuators, temperature sensors |

| Binary Ni-Ti (Commercial Grade) | Ni 55%, Ti 45% | 200 – 300 | Industrial tubing, general engineering |

| Ni-Ti-Cu Alloy | Ni 50%, Ti 45%, Cu 5% | 270 – 420 | Low hysteresis actuators |

Price Comparison: Ni-Ti vs. Stainless Steel and Nickel Tubing

Ni-Ti tubes are significantly more expensive than stainless steel or pure nickel tubing due to advanced production techniques and material behavior control. The following table compares pricing and performance:

| Material Type | Price Range (USD/kg) | Key Feature | Common Application |

|---|---|---|---|

| Ni-Ti Alloy | 200 – 400 | Shape memory, superelastic | Medical, robotics, aerospace |

| Nickel Alloy | 40 – 80 | High corrosion resistance | Industrial and chemical |

| Stainless Steel | 10 – 25 | Durable, cost-effective | General instrumentation |

Applications Affecting Ni-Ti Tube Pricing

Ni-Ti capillary tubes are used in applications that require both flexibility and precision. Each industry sets unique requirements that directly affect cost and processing time.

| Industry | Specification Requirement | Cost Level |

|---|---|---|

| Medical Devices | Biocompatible, micro-diameter, tight tolerance | Very High |

| Robotics | High flexibility, cyclic durability | High |

| Aerospace | Shape recovery under thermal stress | High |

| Electronics | Precision miniature tubing | Medium |

| Research and Prototyping | Custom shapes and experimental alloys | Medium to High |

Market Trends and Future Outlook

The global Ni-Ti market is projected to grow steadily as innovations in medical and automation technologies expand. With increasing investment in minimally invasive medical devices and smart actuators, the demand for Ni-Ti tubing will rise. However, the price is expected to remain high due to limited nickel and titanium supply chains, as well as expensive processing techniques. Manufacturers are focusing on recycling Ni-Ti scrap and improving alloy yield to stabilize pricing in the coming years.

Supplier Selection and Cost Optimization

When purchasing Ni-Ti capillary tubes, buyers should evaluate suppliers based on production capability, certification, and customization options.

| Supplier Evaluation Criteria | Importance |

|---|---|

| ISO 13485 Certification | Essential for medical-grade Ni-Ti tubes |

| Vacuum Melting Capability | Ensures purity and uniform alloy composition |

| Dimensional Precision | Important for micro-scale applications |

| Surface Treatment Options | Electropolishing or passivation enhances corrosion resistance |

| Delivery Lead Time | Faster turnaround improves project efficiency |

Related Questions

1. What is the average price of Ni-Ti capillary tube per meter?

The average price ranges between USD 15 and USD 45 per meter depending on diameter, alloy type, and surface finish. Medical-grade tubes are usually at the higher end.

2. Why is Ni-Ti tubing more expensive than stainless steel?

Ni-Ti tubing is more costly because it requires precise alloy control, advanced heat treatment, and strict quality testing to achieve shape memory and elasticity properties not found in stainless steel.

3. Where can I purchase Ni-Ti capillary tubes?

Ni-Ti capillary tubes can be sourced from specialized suppliers such as SAES Getters, Fort Wayne Metals, and NDC Tubes. Always confirm medical or industrial certifications before ordering.