Nickel 200 and Nickel 201 bars are pure nickel alloys that provide excellent corrosion resistance, good mechanical strength, and outstanding electrical and thermal conductivity. Nickel 200 is a commercially pure wrought nickel with a maximum carbon content of 0.15%, while Nickel 201 is a low-carbon modification with a maximum carbon content of 0.02%. When purchased directly from a factory, these bars are supplied at competitive prices and with guaranteed quality standards such as ASTM B160 and ASME SB160. They are widely used in chemical processing, food handling, electronics, and marine applications.

Chemical Composition of Nickel 200 and Nickel 201 Bars

The primary element in both Nickel 200 and Nickel 201 is nickel, with only minor differences in carbon content. This slight variation improves high-temperature resistance in Nickel 201.

| Grade | Nickel (Ni) | Carbon (C) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Silicon (Si) | Sulfur (S) |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 99.0 min | 0.15 max | 0.40 max | 0.25 max | 0.35 max | 0.35 max | 0.01 max |

| Nickel 201 | 99.0 min | 0.02 max | 0.40 max | 0.25 max | 0.35 max | 0.35 max | 0.01 max |

Mechanical Properties of Nickel 200 and Nickel 201 Bars

Both Nickel 200 and Nickel 201 offer excellent mechanical properties, especially in reducing conditions and neutral solutions. Below are their typical mechanical properties:

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRB) | Density (g/cm³) |

|---|---|---|---|---|---|

| Nickel 200 | 380 | 105 | 40 | 60 | 8.89 |

| Nickel 201 | 370 | 100 | 40 | 55 | 8.89 |

Applications of Nickel 200 and Nickel 201 Bars

Factories produce Nickel 200 and Nickel 201 bars for industries requiring high resistance to corrosive media and electrical conductivity.

| Industry | Applications |

|---|---|

| Chemical Processing | Reactors, heat exchangers, piping systems |

| Electronics | Battery components, electrical conductors |

| Food Industry | Handling equipment, caustic soda production |

| Marine | Seawater systems, pump shafts |

| Power Generation | Nuclear reactor components, fuel handling |

Advantages of Buying Direct from Factory

Ordering Nickel 200 and Nickel 201 bars directly from a factory ensures:

- Lower prices without distributor markups

- Customized sizes and finishes (bright, polished, forged)

- Mill test certificates and compliance with ASTM/ASME standards

- Stable supply chain with bulk availability

- Technical support and after-sales service

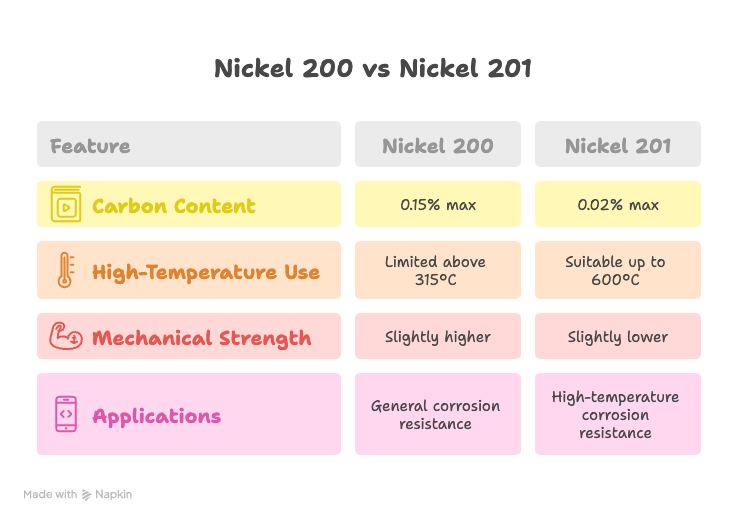

Nickel 200 vs Nickel 201 Comparison

Although similar, Nickel 200 and Nickel 201 are selected based on operating conditions. The table below highlights the differences:

| Feature | Nickel 200 | Nickel 201 |

|---|---|---|

| Carbon Content | 0.15% max | 0.02% max |

| High-Temperature Use | Limited above 315°C | Suitable up to 600°C |

| Mechanical Strength | Slightly higher | Slightly lower |

| Applications | General corrosion resistance | High-temperature corrosion resistance |

Related Questions and Answers

What is the main difference between Nickel 200 and Nickel 201 bars?

The primary difference is carbon content. Nickel 201 has lower carbon, which improves its performance in high-temperature applications compared to Nickel 200.

Are Nickel 200 and 201 bars expensive?

Yes, they are more expensive than stainless steel due to high nickel purity, but their corrosion resistance and durability reduce long-term costs.

Which industries prefer Nickel 201 over Nickel 200?

Nickel 201 is preferred in industries requiring high-temperature resistance, such as chemical plants and power generation, where temperatures can exceed 315°C.