Nickel 200 round bar, corresponding to UNS N02200, is a commercially pure nickel alloy known for its excellent corrosion resistance, mechanical strength, and thermal and electrical conductivity. Purchasing directly from factories allows buyers to get competitive pricing while ensuring material quality. This article provides a detailed overview of Nickel 200 round bar, including specifications, properties, manufacturing, applications, and pricing considerations.

Nickel 200 Round Bar: Basics and Grade

Nickel 200 is essentially pure nickel with a minimum 99% nickel content. It is widely used in industrial applications requiring high resistance to corrosive environments and durability at elevated temperatures. The bars are manufactured to precise standards and are available in a variety of diameters, lengths, and finishes.

Chemical Composition

| Element | Maximum / Minimum (%) |

|---|---|

| Nickel (Ni) | ≥ 99.0 |

| Iron (Fe) | ≤ 0.40 |

| Carbon (C) | ≤ 0.15 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.25 |

| Sulfur (S) | ≤ 0.01 |

Physical & Mechanical Properties

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ |

| Melting Point | ~1446 °C |

| Tensile Strength (annealed) | ~462 MPa |

| Yield Strength (0.2% offset) | ~148 MPa |

| Elongation (in 50 mm) | ~45% |

| Hardness (HRB, annealed) | 45–70 |

Standards and Equivalents

Nickel 200 round bar is produced according to ASTM B160 standards and equivalent specifications in other countries. Equivalent grades include Werkstoff 2.4066, DIN 2.4066, EN Ni 99.2, and JIS NW 2200.

Size, Form & Manufacturing Range

Factory suppliers offer Nickel 200 round bars in diameters from 3 mm to 800 mm and lengths from 1 m to 6 m, with custom lengths available. The bars may have bright, turned, or black finishes and are supplied in hot-finished, cold-drawn, or annealed conditions.

Corrosion Resistance & Application Advantages

Nickel 200 round bars are highly resistant to reducing acids, caustic solutions, and seawater. They are used in chemical processing, desalination, marine applications, aerospace, electronics, and heat exchangers due to their ductility, thermal and electrical conductivity, and high temperature strength.

Factory Pricing & Cost Factors

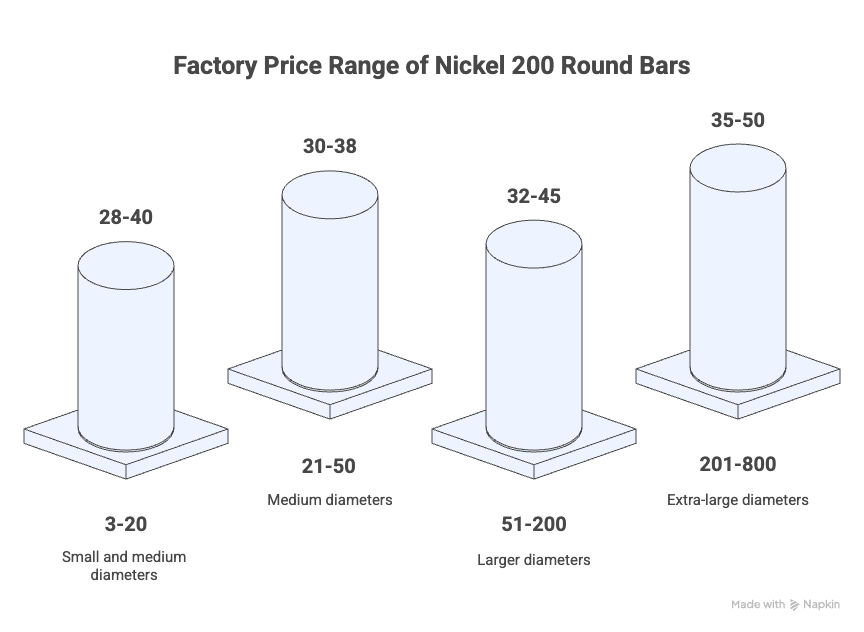

Factory prices vary depending on diameter, finish, and quantity. Bulk orders typically lower per-kg costs. Below is an example of price ranges:

| Diameter (mm) | Price per kg (USD) | Notes |

|---|---|---|

| 3–20 | 28–40 | Small and medium diameters |

| 21–50 | 30–38 | Medium diameters |

| 51–200 | 32–45 | Larger diameters |

| 201–800 | 35–50 | Extra-large diameters |

Factory Sourcing Strategies

To achieve factory-level pricing:

- Request quotations directly from certified factories.

- Specify alloy grade (N02200), diameter, length, finish, and heat treatment.

- Place bulk orders to lower unit cost.

- Ask for material test certificates and specification compliance.

- Consider production lead times and shipping logistics.

Handling and Storage Considerations

- Store bars in a dry environment to prevent surface contamination.

- Avoid exposure to strongly oxidizing acids.

- Use proper machining tools for cutting and forming nickel bars.

- Inspect for surface defects or cracks before use.

Quality Assurance and Testing

| Test / Certificate | Purpose |

|---|---|

| Material Test Certificate (MTC) | Certifies chemical composition and mechanical properties |

| Ultrasonic or Eddy-Current Inspection | Detects internal flaws |

| Dimensional Inspection Report | Ensures diameter, straightness, and tolerance meet specifications |

| Positive Material Identification (PMI) | Verifies correct alloy |

Comparison: Factory Bar vs Distributor Bar

| Aspect | Factory Purchase | Distributor Purchase |

|---|---|---|

| Unit Price | Lower per kg | Higher due to markup |

| Lead Time | Longer | Shorter (stocked items) |

| Certifications | Full traceability | May lack mill-level traceability |

| Customization | High | Limited |

Related Questions:

1. What is the factory price of Nickel 200 round bar per kilogram?

The factory price of Nickel 200 round bar generally ranges from 28 to 50 USD per kilogram depending on diameter, length, and finish.

2. What are the standard sizes available for Nickel 200 round bar?

Nickel 200 round bars are available in diameters from 3 mm to 800 mm and lengths from 1 m to 6 m, with custom lengths also available.

3. What mechanical properties can I expect from Nickel 200 round bar?

In annealed condition, Nickel 200 round bars have a tensile strength of approximately 462 MPa, yield strength around 148 MPa, elongation of ~45%, and hardness of HRB 45–70.