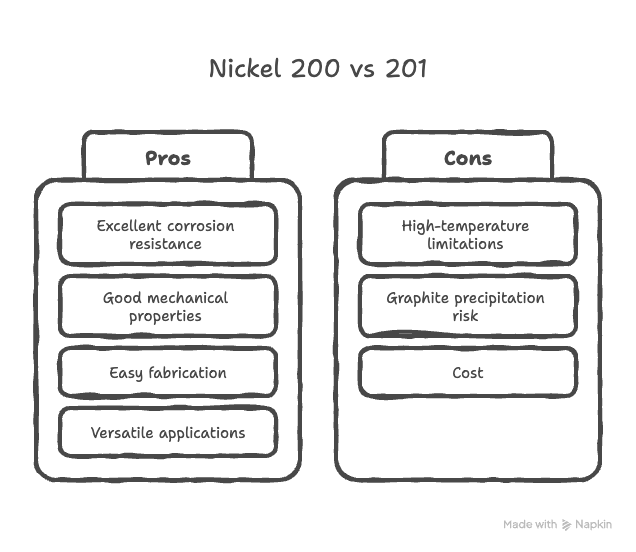

Nickel 200 and Nickel 201 are commercially pure wrought nickel alloys widely used in chemical processing, electronics, aerospace, and high-temperature applications. While these two grades are very similar in composition and corrosion resistance, they differ mainly in carbon content, which significantly affects their performance at elevated temperatures. Understanding the differences between Nickel 200 and Nickel 201 helps engineers and buyers choose the correct material for their operating conditions.

What Is Nickel 200?

Nickel 200 is a commercially pure nickel alloy containing a minimum of 99.0% nickel. It offers excellent resistance to corrosion, particularly in reducing environments, and provides good mechanical properties across a wide temperature range. Nickel 200 is widely used in chemical processing, food handling, and electronics due to its purity and stability.

What Is Nickel 201?

Nickel 201 is essentially a low-carbon version of Nickel 200. It contains the same high nickel content but with a much lower carbon level, which prevents graphite precipitation at elevated temperatures. This makes Nickel 201 more suitable for high-temperature applications where long-term exposure above 315°C (600°F) is required.

Chemical Composition Comparison

| Element | Nickel 200 | Nickel 201 |

|---|---|---|

| Nickel (Ni) | 99.0 min | 99.0 min |

| Carbon (C) | ≤ 0.15 | ≤ 0.02 |

| Iron (Fe) | ≤ 0.40 | ≤ 0.40 |

| Manganese (Mn) | ≤ 0.35 | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 | ≤ 0.35 |

| Copper (Cu) | ≤ 0.25 | ≤ 0.25 |

Mechanical Properties Comparison

The mechanical properties of Nickel 200 and Nickel 201 are very similar at room temperature, but differences become important at elevated temperatures.

| Property | Nickel 200 | Nickel 201 |

|---|---|---|

| Tensile Strength | ≈ 70–85 ksi (480–585 MPa) | ≈ 70–85 ksi (480–585 MPa) |

| Yield Strength | ≈ 20–35 ksi (140–240 MPa) | ≈ 20–35 ksi (140–240 MPa) |

| Elongation | ≈ 30–45% | ≈ 30–45% |

| Maximum Recommended Service Temperature | Up to 315°C (600°F) | Up to 600°C (1110°F) |

High-Temperature Performance

The key difference between Nickel 200 and Nickel 201 lies in high-temperature behavior. Nickel 200 contains higher carbon, which can lead to graphite precipitation when exposed to temperatures above 315°C for extended periods. This can reduce ductility and mechanical strength. Nickel 201, with its ultra-low carbon content, eliminates this risk and is therefore preferred for high-temperature service.

Corrosion Resistance

Both Nickel 200 and Nickel 201 offer excellent resistance to corrosion in a wide range of environments:

– Resistant to caustic alkalis, organic acids, and dry gases

– Excellent performance in reducing environments

– Good resistance to seawater under controlled conditions

Because their chemical compositions are nearly identical except for carbon, their corrosion resistance is essentially the same.

Fabrication and Weldability

Nickel 200 and Nickel 201 are easy to fabricate using standard forming, machining, and welding techniques. Both alloys can be cold-worked, hot-worked, and welded using conventional nickel alloy welding methods. Nickel 201 is often preferred for welded components used in high-temperature environments due to its improved structural stability.

Applications Comparison

Typical applications vary depending on operating temperature:

Nickel 200: Chemical processing equipment, food handling equipment, electronics components, battery components, heat exchangers operating at moderate temperatures.

Nickel 201: High-temperature chemical processing equipment, furnace components, heat treatment baskets, aerospace components requiring purity and thermal stability.

How to Choose Between Nickel 200 and Nickel 201

Nickel 200 is suitable for applications where service temperatures remain below 315°C and where corrosion resistance and purity are the main requirements. Nickel 201 should be selected when higher operating temperatures are involved or when long-term thermal stability is critical.

Related Questions

What is the main difference between Nickel 200 and Nickel 201?

The main difference is carbon content. Nickel 201 has much lower carbon, making it suitable for high-temperature applications.

Can Nickel 200 be used at high temperatures?

Nickel 200 is not recommended for continuous service above 315°C due to the risk of graphite precipitation.

Is Nickel 201 more expensive than Nickel 200?

Nickel 201 is typically slightly more expensive due to stricter carbon control, but the price difference is usually minimal compared to performance benefits.