Nickel alloy 625 tubing, also known as Inconel 625 tubing, is a high-strength and corrosion-resistant material widely used in industries such as chemical processing, aerospace, marine, and power generation. It is composed mainly of nickel, with additions of chromium, molybdenum, and niobium that enhance its ability to withstand extreme environments, high temperatures, and aggressive chemicals. This article provides a detailed overview of the properties, applications, advantages, and pricing factors of nickel alloy 625 tubing.

Chemical Composition of Nickel Alloy 625 Tubing

The unique composition of alloy 625 gives it outstanding mechanical strength and resistance to oxidation and corrosion. Below is a detailed table showing the chemical composition range:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb+Ta) | 3.15 – 4.15 |

| Iron (Fe) | 5.0 max |

| Carbon (C) | 0.10 max |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties of Nickel Alloy 625 Tubing

Nickel alloy 625 tubing exhibits high tensile strength, excellent fatigue resistance, and good weldability. Below are the key mechanical properties in typical conditions:

| Property | Value |

|---|---|

| Tensile Strength | 827 MPa min |

| Yield Strength (0.2% offset) | 414 MPa min |

| Elongation | 30% min |

| Hardness (Rockwell B) | ≤ 95 |

| Density | 8.44 g/cm³ |

| Melting Point | 1290 – 1350°C |

Key Features of Nickel Alloy 625 Tubing

Several unique features make alloy 625 tubing suitable for harsh service conditions:

- Excellent resistance to pitting, crevice corrosion, and intergranular attack

- High resistance to chloride-ion stress corrosion cracking

- Outstanding fatigue and creep rupture strength

- Wide temperature range usability from cryogenic to 982°C

- Good weldability and fabricability without post-weld heat treatment

Applications of Nickel Alloy 625 Tubing

The versatility of nickel alloy 625 tubing allows its use in various industries. Below is an industry-wise application table:

| Industry | Applications |

|---|---|

| Chemical Processing | Heat exchangers, reactor vessels, chemical piping |

| Aerospace | Exhaust systems, jet engine components, turbine seals |

| Marine | Seawater piping, submarine parts, offshore platforms |

| Power Generation | Steam lines, superheater tubing, pollution control systems |

| Oil & Gas | Downhole tubing, risers, processing equipment |

Advantages of Using Nickel Alloy 625 Tubing

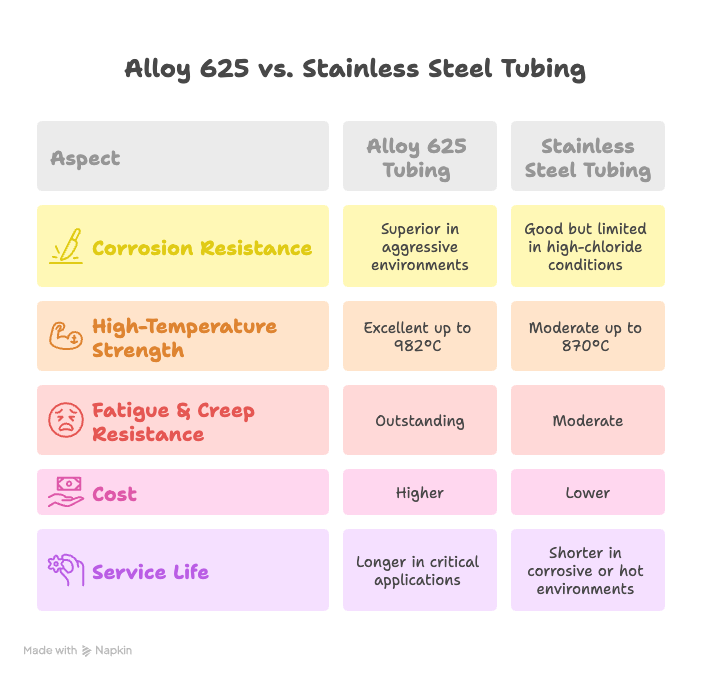

Compared with stainless steel or other alloys, nickel alloy 625 tubing offers unique advantages:

| Aspect | Nickel Alloy 625 Tubing | Stainless Steel Tubing |

|---|---|---|

| Corrosion Resistance | Superior in aggressive environments | Good but limited in high-chloride conditions |

| High-Temperature Strength | Excellent up to 982°C | Moderate up to 870°C |

| Fatigue & Creep Resistance | Outstanding | Moderate |

| Cost | Higher | Lower |

| Service Life | Longer in critical applications | Shorter in corrosive or hot environments |

Factors Affecting Nickel Alloy 625 Tubing Price

The cost of alloy 625 tubing depends on several factors, such as:

- Global nickel and molybdenum market trends

- Production process (seamless vs welded tubing)

- Dimensions and wall thickness requirements

- Order quantity and delivery terms

- Supplier location and certifications

Related Questions and Answers

What is nickel alloy 625 tubing used for?

Nickel alloy 625 tubing is used in chemical plants, aerospace engines, marine systems, and oil & gas equipment where corrosion resistance and strength are critical.

Is alloy 625 tubing expensive?

Yes, nickel alloy 625 tubing is more expensive than stainless steel due to its high nickel, chromium, and molybdenum content, but its durability reduces replacement costs over time.

Can nickel alloy 625 tubing be welded easily?

Yes, alloy 625 tubing has excellent weldability and does not require post-weld heat treatment, making it a preferred material for fabrication.