Nickel alloy bars such as UNS N06600 (Inconel 600) and UNS N06625 (Inconel 625) are widely produced in specialized factories for demanding industrial applications. These alloys are known for their superior corrosion resistance, mechanical strength, and high-temperature performance. By purchasing directly from a factory, customers benefit from competitive prices, customized dimensions, and reliable mill certification according to standards such as ASTM B166 (for N06600) and ASTM B446 (for N06625).

Chemical Composition of N06600 and N06625 Bars

| Grade | Nickel (Ni) | Chromium (Cr) | Iron (Fe) | Molybdenum (Mo) | Niobium + Ta | Carbon (C) | Manganese (Mn) | Silicon (Si) |

|---|---|---|---|---|---|---|---|---|

| UNS N06600 (Inconel 600) | 72.0 min | 14.0-17.0 | 6.0-10.0 | — | — | 0.15 max | 1.0 max | 0.5 max |

| UNS N06625 (Inconel 625) | 58.0 min | 20.0-23.0 | 5.0 max | 8.0-10.0 | 3.15-4.15 | 0.10 max | 0.5 max | 0.5 max |

Mechanical Properties of N06600 and N06625 Bars

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) | Melting Range (°C) |

|---|---|---|---|---|---|

| UNS N06600 | 655 | 240 | 30 | 8.47 | 1354–1413 |

| UNS N06625 | 827 | 414 | 30 | 8.44 | 1290–1350 |

Applications of Nickel Alloy Bars N06600 & N06625

Factories manufacture N06600 and N06625 bars for industries requiring reliable high-performance alloys:

| Industry | N06600 (Inconel 600) | N06625 (Inconel 625) |

|---|---|---|

| Chemical Processing | Heat exchangers, evaporators, process piping | Acid plant equipment, scrubbers, seawater systems |

| Aerospace | Engine components, turbine seals | Jet engine exhausts, turbine casings |

| Power Generation | Nuclear reactor vessels, steam generators | Superheater tubes, boiler components |

| Marine | Pumps and valves for brine handling | Offshore oil & gas risers, subsea equipment |

| Electronics | Battery production equipment | High-performance connectors |

Advantages of Buying Direct from Factory

- Factory price advantage with no middleman markups

- Wide stock range: hot rolled, forged, polished, and bright bars

- Compliance with ASTM/ASME standards (B166, B446)

- Mill Test Certificates (MTC) provided

- Custom length and diameter options

- Strong packaging suitable for global shipment

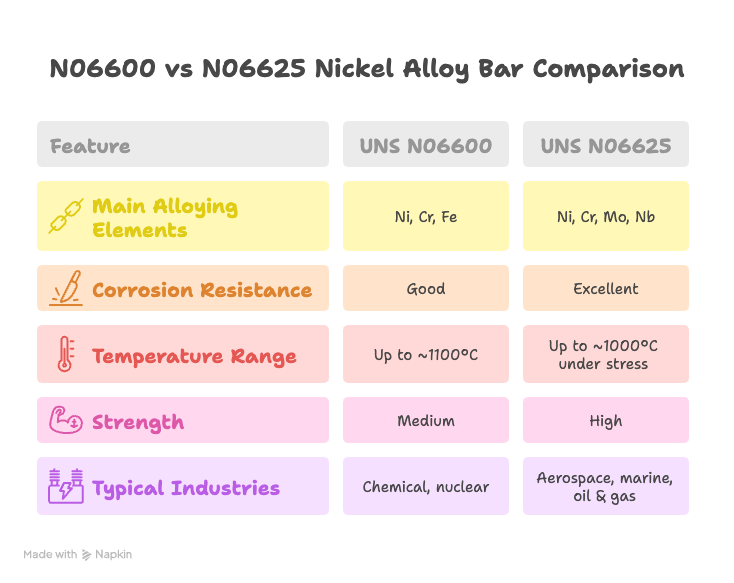

N06600 vs N06625 Comparison

| Feature | UNS N06600 | UNS N06625 |

|---|---|---|

| Main Alloying Elements | Ni, Cr, Fe | Ni, Cr, Mo, Nb |

| Corrosion Resistance | Good in oxidizing/reducing conditions | Excellent, especially against seawater and acids |

| Temperature Range | Up to ~1100°C | Up to ~1000°C under stress |

| Strength | Medium | High (due to Nb and Mo) |

| Typical Industries | Chemical, nuclear | Aerospace, marine, oil & gas |

Related Questions and Answers

What is the main difference between N06600 and N06625 nickel alloy bars?

The difference lies in alloying. N06600 (Inconel 600) contains mainly nickel, chromium, and iron, providing oxidation resistance, while N06625 (Inconel 625) has added molybdenum and niobium for superior strength and seawater corrosion resistance.

Which industries prefer N06625 bars over N06600?

Marine, offshore oil & gas, and aerospace industries often prefer N06625 due to its higher strength and resistance to seawater and chloride stress cracking.

Are factory prices more competitive than distributor prices?

Yes. Ordering directly from a nickel alloy bar factory reduces costs by eliminating distributor margins and ensures reliable traceability with mill test certifications.