Nickel alloy pipe fittings are critical components in high-performance piping systems, particularly in industries that demand exceptional corrosion resistance, strength at elevated temperatures, and durability. These fittings are extensively used in oil and gas, petrochemical, marine, nuclear, and aerospace applications. The manufacturers of nickel alloy pipe fittings play a key role in ensuring quality, compliance with international standards, and availability across global markets.

What Are Nickel Alloy Pipe Fittings?

Nickel alloy pipe fittings are components used to connect sections of pipe or tube in systems transporting fluids or gases. Made from various nickel-based alloys, these fittings include elbows, tees, reducers, couplings, and caps. They are chosen for their resistance to heat, corrosion, and pressure in demanding environments such as chemical plants and offshore drilling platforms.

Types of Nickel Alloys Used in Pipe Fittings

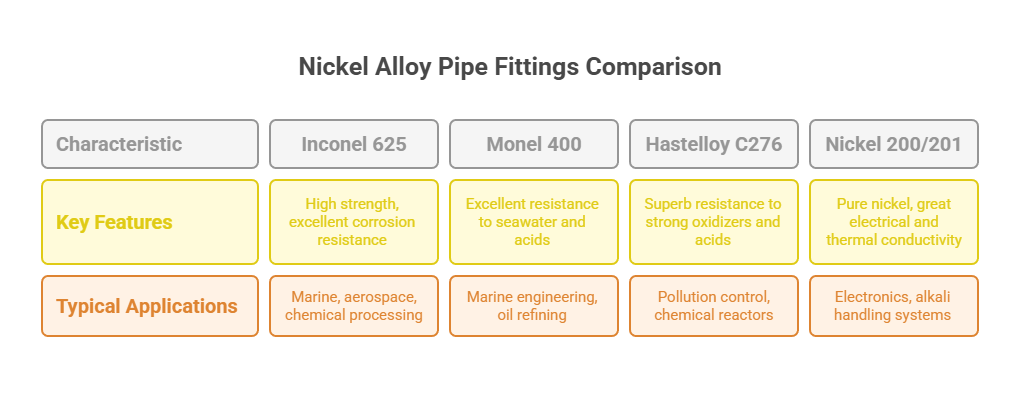

| Nickel Alloy | Key Features | Typical Applications |

|---|---|---|

| Inconel 625 | High strength, excellent corrosion resistance | Marine, aerospace, chemical processing |

| Monel 400 | Excellent resistance to seawater and acids | Marine engineering, oil refining |

| Hastelloy C276 | Superb resistance to strong oxidizers and acids | Pollution control, chemical reactors |

| Nickel 200/201 | Pure nickel, great electrical and thermal conductivity | Electronics, alkali handling systems |

Top Global Manufacturers of Nickel Alloy Pipe Fittings

| Company | Country | Specialty |

|---|---|---|

| PCC (Precision Castparts Corp.) | USA | High-performance alloy fittings for aerospace and energy |

| Special Metals Corporation | USA | Inconel and Monel alloy components |

| NeoNickel | UK | Wide range of corrosion-resistant alloy fittings |

| Rajendra Industrial Corporation | India | Custom nickel alloy fittings for global markets |

| Ramesh Group | India | ASME/ASTM-certified alloy pipe fittings |

Manufacturing Standards and Certifications

Reputable nickel alloy pipe fitting manufacturers adhere to international standards and certifications to ensure product quality and compatibility. Common standards include:

| Standard | Description |

|---|---|

| ASTM B366 | Standard specification for wrought nickel and nickel alloy fittings |

| ASME B16.9 | Factory-made wrought butt-welding fittings |

| EN 10253 | European standard for butt-weld pipe fittings |

| NACE MR0175 | Sour service compliance for use in oil and gas fields |

Applications and Industrial Demand

Nickel alloy pipe fittings are indispensable in highly corrosive or high-temperature environments. Key sectors demanding these fittings include:

Oil & Gas: Resistance to sour gas, high pressure, and extreme temperatures makes nickel alloys ideal for upstream and midstream operations.

Chemical & Petrochemical: Compatibility with aggressive acids and bases ensures process integrity and safety.

Power Generation: Used in nuclear and thermal plants due to their durability under radiation and heat.

Aerospace: Fittings made from Inconel and Hastelloy withstand high temperatures and pressure differentials in aircraft systems.

Advantages of Buying from Certified Manufacturers

Working with certified nickel alloy pipe fittings manufacturers offers several advantages:

1. Material Traceability: Reliable manufacturers provide mill test reports (MTRs) and full traceability back to the raw material batch.

2. Global Standards Compliance: Components are designed to meet ASME, ASTM, ISO, and PED standards.

3. Customization and Engineering Support: Many top suppliers offer custom fabrication, non-standard sizes, and CAD drawing support.

4. Export Capabilities: Established players have certifications for global exports including CE, API, and ISO 9001.

Pricing Factors of Nickel Alloy Pipe Fittings

| Factor | Impact on Price |

|---|---|

| Raw Material Cost | Nickel price fluctuations heavily impact final fitting cost |

| Fitting Type and Size | Larger and more complex shapes (like reducers and tees) cost more |

| Standards & Testing | Additional certifications (like NACE, PMI testing) add to cost |

| Surface Finish & Coating | Electropolishing or passivation increases pricing |

Frequently Asked Questions

Who are the top manufacturers of nickel alloy pipe fittings?

Some of the top global manufacturers include PCC (USA), Special Metals (USA), NeoNickel (UK), Rajendra Industrial Corporation (India), and Ramesh Group (India). These companies offer a wide range of ASME/ASTM-compliant nickel alloy fittings.

What standards apply to nickel alloy pipe fittings?

Key standards include ASTM B366, ASME B16.9, EN 10253, and NACE MR0175, which cover material composition, dimensions, pressure ratings, and corrosive service compatibility.

Why choose nickel alloy fittings over stainless steel?

Nickel alloys provide superior resistance to extreme temperatures, pressure, and corrosive media, especially in offshore, chemical, and nuclear applications. While more expensive than stainless steel, they offer longer service life and better performance in harsh environments.