Nickel alloy powder factory is a highly searched topic among buyers in additive manufacturing, powder metallurgy, thermal spray coating, and aerospace material sourcing. This article explains what a nickel alloy powder factory produces, how different manufacturing processes affect powder quality, key performance indicators buyers should check, and how various alloys compare across applications. Multiple tables are included to provide a clear, structured overview for engineers and procurement specialists.

What a Nickel Alloy Powder Factory Produces

A nickel alloy powder factory mainly manufactures spherical or irregular powder forms used in high-temperature, corrosion-resistant, and high-strength applications. Powder properties such as particle size, morphology, flowability, and oxygen content directly affect performance.

| Product Type | Description |

| Nickel-based Superalloy Powders | Inconel, Hastelloy, Rene, Waspaloy powder for AM & PM |

| Thermal Spray Powders | Used for PTA, HVOF, plasma spraying |

| Self-Fluxing Nickel Powders | Nickel-chromium-boron-silicon powders for surface hardening |

| Custom Alloy Powders | Special compositions for research or aerospace needs |

Main Manufacturing Processes in a Nickel Alloy Powder Factory

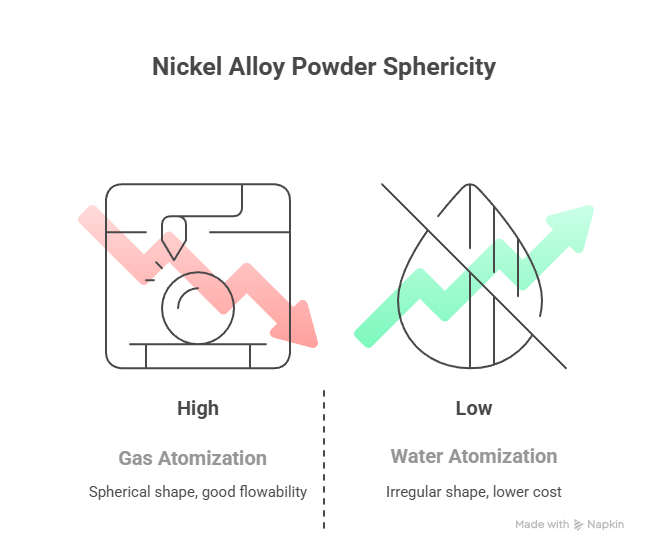

The production method greatly influences powder characteristics. Gas atomization is preferred for additive manufacturing because it produces clean and spherical particles.

| Process | Powder Characteristics |

| Gas Atomization | Spherical shape, good flowability, low oxygen |

| Water Atomization | Irregular shape, lower cost |

| Plasma Atomization | Very spherical, best for AM titanium & high-end alloys |

| Mechanical Alloying | Non-spherical, used for specialty alloy development |

Common Nickel Alloy Powders Produced

Factories often produce many alloy grades to meet different industrial needs. Inconel alloys are the most widely used due to their strength and corrosion resistance.

| Alloy | Main Features |

| Inconel 718 Powder | Excellent strength; widely used in 3D printing |

| Inconel 625 Powder | High corrosion resistance; chemical & marine use |

| Rene 41 Powder | Super-high temperature alloy for aerospace hot sections |

| Hastelloy X Powder | High heat resistance for furnace parts |

| Waspaloy Powder | High strength at extreme temperatures |

Quality Standards Adopted by Nickel Alloy Powder Factories

Most factories follow international standards to ensure high performance and reliability, especially for aerospace or energy industries.

| Standard | Specification |

| AMS (Aerospace Material Specifications) | Defines mechanical, chemical, and cleanliness requirements |

| ASTM | Standard testing and material specifications |

| ISO | General quality management and powder testing |

| OEM-Specific Specs | Custom requirements for turbine or aviation companies |

Key Properties to Check When Purchasing Nickel Alloy Powder

Engineers and buyers should evaluate several technical parameters to ensure the powder meets the application’s performance requirements.

| Parameter | Importance |

| Particle Size Distribution | Affects build density and flowability |

| Oxygen & Nitrogen Content | Critical for mechanical properties in AM |

| Sphericity | Higher sphericity improves powder packing |

| Flow Rate | Influences printing or spraying stability |

| Chemical Composition | Must meet alloy spec and heat batch consistency |

Applications of Nickel Alloy Powder

Nickel alloy powders serve a wide range of demanding industries due to their ability to maintain strength at high temperatures and resist corrosion.

| Industry | Typical Use |

| Aerospace | Turbine blades, engine components, rocket parts |

| Additive Manufacturing | 3D-printed high-performance parts |

| Thermal Spray | Wear-resistant coatings, repair coatings |

| Energy & Power | Gas turbine parts, furnace components |

| Chemical Industry | High corrosion-resistant parts |

How to Evaluate a Nickel Alloy Powder Factory

When selecting a factory, buyers should assess production ability, quality control, and certification systems.

| Evaluation Item | What to Check |

| Production Capacity | Can the factory supply consistent volume? |

| Atomization Equipment | Gas atomization is preferred for premium powder |

| Testing Instruments | PSD analyzer, ICP, oxygen analyzer |

| Certifications | ISO, AMS compliance, aviation approvals |

| Experience | Years of operation and customer references |

Comparison: High-End vs Regular Nickel Alloy Powder Factories

Some factories specialize in aerospace-grade materials, while others target more general industrial applications.

| Factory Type | Main Features |

| High-End Aerospace Suppliers | Strict AMS specs, very low oxygen, expensive |

| General Industrial Powder Factories | Lower cost, wider product range, moderate specs |

| Custom Alloy Factories | R&D-focused, flexible composition development |

FAQ About Nickel Alloy Powder Factory

What does a nickel alloy powder factory mainly produce?

It mainly produces spherical nickel-based powders such as Inconel 718, 625, Rene alloys, and Hastelloy powders for additive manufacturing, thermal spray, and powder metallurgy.

How can I evaluate the quality of a nickel alloy powder factory?

You should check its atomization technology, testing equipment, certifications, production capacity, and alloy stability across batches.

Which industries most commonly use nickel alloy powder?

The most common industries include aerospace, additive manufacturing, thermal spray coating, gas turbines, and chemical processing equipment.