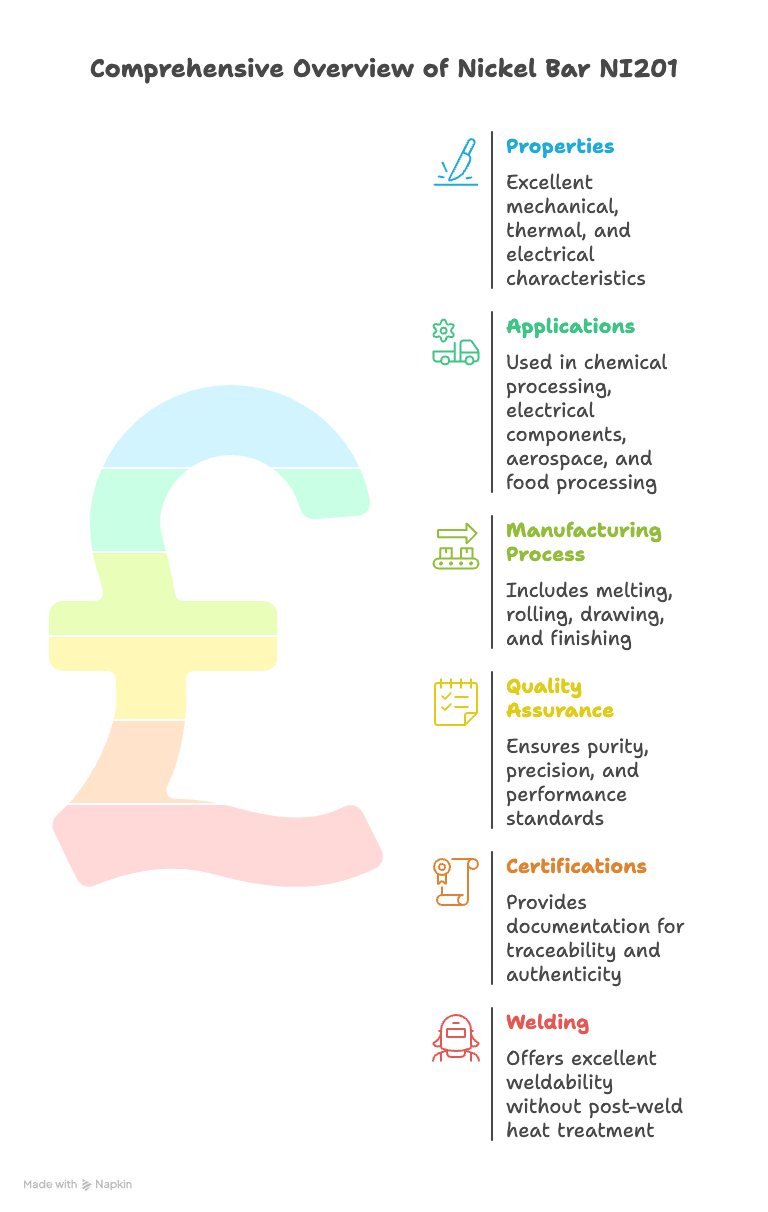

Nickel Bar NI201 is a commercially pure wrought nickel with excellent mechanical, thermal, and electrical properties. As a high-quality industrial material, NI201 is widely used in chemical processing, electrical components, aerospace applications, and food processing equipment. Choosing a reliable Nickel Bar NI201 factory ensures consistency in purity, precision, and performance standards that meet global requirements such as ASTM B160 and UNS N02201.

Nickel Bar NI201 Factory Overview

A Nickel Bar NI201 factory typically specializes in producing nickel bars with strict control over purity (≥99.6% Ni). The manufacturing process includes melting, hot rolling, cold drawing, and surface finishing to achieve precise dimensions and uniform grain structure. NI201 is preferred over NI200 when lower carbon content is needed to avoid embrittlement at higher temperatures.

Nickel Bar NI201 Chemical Composition

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | ≥99.6 |

| Carbon (C) | ≤0.02 |

| Copper (Cu) | ≤0.25 |

| Iron (Fe) | ≤0.40 |

| Manganese (Mn) | ≤0.35 |

| Silicon (Si) | ≤0.35 |

| Sulfur (S) | ≤0.01 |

Mechanical Properties of Nickel Bar NI201

| Property | Value |

|---|---|

| Tensile Strength | 380 MPa |

| Yield Strength (0.2% offset) | 105 MPa |

| Elongation | 40% |

| Hardness (Rockwell B) | 50 HRB |

Applications of Nickel Bar NI201

Nickel Bar NI201 is used in multiple industries that require superior corrosion resistance and electrical conductivity. Its stability in high-temperature and caustic environments makes it suitable for:

1. Chemical Processing: Used for caustic evaporators, reaction vessels, and piping systems due to excellent resistance to alkalis.

2. Electrical Components: Utilized in battery terminals, lead wires, and electrical connectors because of its high conductivity.

3. Aerospace & Marine Industry: Ideal for engine components and seawater equipment requiring strong corrosion resistance.

4. Food & Pharmaceutical Equipment: Suitable for handling pure water, salts, and acids without contamination.

Nickel Bar NI201 Factory Production Process

The production of Nickel Bar NI201 follows a precise metallurgical route ensuring consistent quality and durability:

| Process Step | Description |

|---|---|

| Raw Material Inspection | Nickel cathodes are inspected for purity and uniformity before melting. |

| Vacuum Melting | Ensures low carbon and oxygen content for optimal ductility. |

| Hot Rolling | Converts ingots into bars with improved grain alignment. |

| Cold Drawing | Enhances surface finish and dimensional accuracy. |

| Annealing | Relieves internal stress and restores ductility. |

| Surface Finishing | Final polishing for smooth surface suitable for precision applications. |

Why Choose a Reliable Nickel Bar NI201 Factory

Selecting a trustworthy factory ensures consistent quality, traceable production batches, and adherence to global standards like ASTM B160 and ASME SB-160. High-end factories offer full mill test certification (MTC), customizable sizes, and various bar types—round, square, and flat.

Nickel Bar NI201 Size Range

| Shape | Diameter/Thickness | Length |

|---|---|---|

| Round Bar | 6mm – 250mm | 1000mm – 6000mm |

| Square Bar | 10mm – 150mm | 1000mm – 6000mm |

| Flat Bar | 10mm – 100mm (Thickness) | 1000mm – 6000mm |

Quality Testing in Nickel Bar NI201 Factories

Before delivery, Nickel Bar NI201 undergoes strict testing to ensure reliability:

• Chemical Analysis: Spectrometer verification for Ni content.

• Mechanical Testing: Tensile, hardness, and elongation tests confirm mechanical integrity.

• Ultrasonic & Eddy Current Testing: Detects internal flaws or inclusions.

• Dimensional Inspection: Ensures tight tolerances and uniform cross-sections.

Packing & Delivery

Factories typically use export-standard packaging such as wooden boxes or iron crates. Bars are wrapped with anti-rust paper and plastic sheets to prevent oxidation during transport. Global delivery is available through air, sea, or express couriers depending on customer requirements.

Related Questions

1. What is the difference between Nickel 200 and Nickel 201 bars?

Nickel 200 and Nickel 201 are both commercially pure nickel alloys. The main difference lies in carbon content—Nickel 201 has a lower carbon level, making it more suitable for high-temperature applications to prevent graphitization.

2. Can Nickel Bar NI201 be welded easily?

Yes, NI201 offers excellent weldability. It can be welded using TIG, MIG, or resistance welding methods without the need for post-weld heat treatment, though proper cleaning before welding is essential to avoid contamination.

3. What certifications do reputable Nickel Bar NI201 factories provide?

Reliable factories usually provide certifications such as Mill Test Certificate (EN 10204 3.1), ISO 9001, and compliance with ASTM B160. These documents ensure traceability, material authenticity, and quality assurance.