Nickel bars are widely used in industries like aerospace, electronics, power generation, and chemical processing due to their excellent corrosion resistance, strength, and thermal stability. Pricing for nickel bars can vary based on grade, purity, form (round, flat, square), and global metal market conditions. This article provides a comprehensive breakdown of current nickel bar prices, influencing factors, and common grades to help buyers and engineers make well-informed purchasing decisions.

Common Grades of Nickel Bars

| Grade | UNS Number | Nickel Content | Common Use |

|---|---|---|---|

| Nickel 200 | N02200 | ≥99.6% | Electronics, chemical equipment |

| Nickel 201 | N02201 | ≥99.6% (low carbon) | High-temperature applications |

| Monel 400 | N04400 | ≈66% | Marine, chemical industry |

| Inconel 625 | N06625 | ≈58% | Aerospace, seawater systems |

| Hastelloy C276 | N10276 | ≈57% | Acid-resistant equipment |

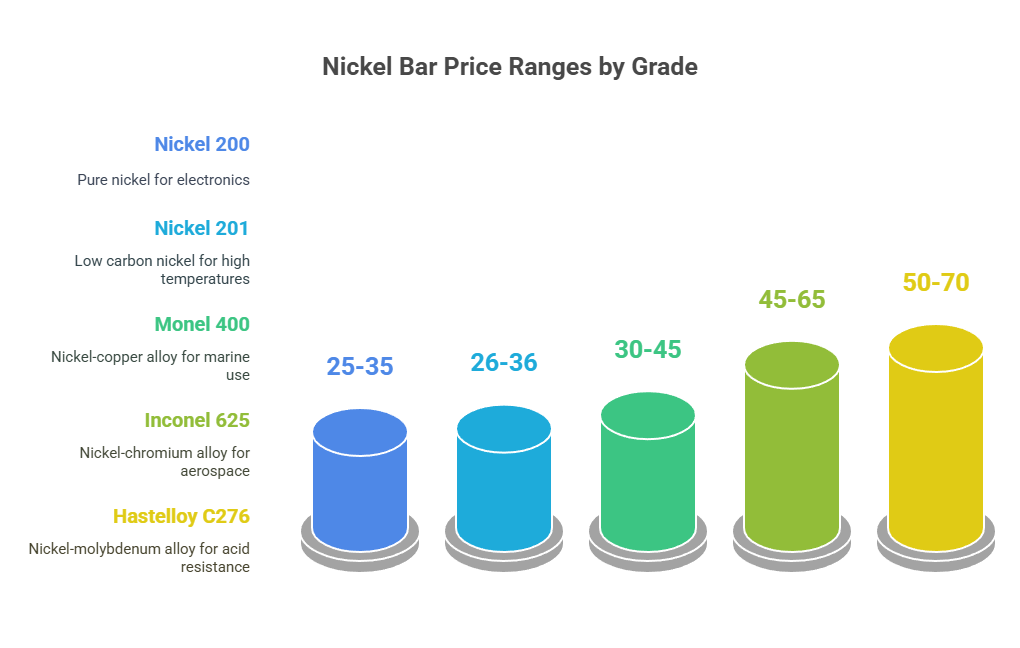

Nickel Bar Price by Grade (USD/KG)

| Grade | Form | Price Range (USD/KG) |

|---|---|---|

| Nickel 200 | Round bar | $25 – $35 |

| Nickel 201 | Square bar | $26 – $36 |

| Monel 400 | Flat bar | $30 – $45 |

| Inconel 625 | Round bar | $45 – $65 |

| Hastelloy C276 | Round bar | $50 – $70 |

Influencing Factors on Nickel Bar Prices

| Factor | Description |

|---|---|

| Nickel Content | Higher nickel content increases price significantly |

| Grade & Alloy | Special alloys (Monel, Inconel, Hastelloy) are priced higher than pure nickel |

| Form & Finish | Precision-cut or polished bars cost more than raw mill finishes |

| Origin | Imported materials from Europe or USA may cost more than those from China or India |

| Market Demand | Prices fluctuate with global nickel demand, especially from battery and EV sectors |

Standard Sizes and Estimated Prices (Nickel 200 Round Bar)

| Diameter (mm) | Length (mm) | Estimated Price (USD/piece) |

|---|---|---|

| 12 | 1000 | $30 – $42 |

| 20 | 1000 | $48 – $62 |

| 30 | 1000 | $72 – $95 |

| 50 | 1000 | $125 – $160 |

Top Suppliers by Region

| Region | Supplier Advantage | Price Level |

|---|---|---|

| China | Mass production, cost-effective | Low |

| India | Wide range of grades, good export volume | Moderate |

| USA | High quality, certified | High |

| Germany | Precision machining, specialty alloys | High |

Applications of Nickel Bars

- Heat exchangers and condensers

- Battery and fuel cell components

- Industrial furnace parts

- Marine and saltwater systems

- Chemical handling equipment

Tips for Buying Nickel Bars

- Choose grade based on corrosion resistance and temperature needs

- Request material test certificates (MTC)

- Check for compliance with ASTM B160, B564, or equivalent standards

- Confirm manufacturer’s reputation and certifications (ISO, PED, etc.)

- Consider purchasing from bulk wholesalers for better pricing

Frequently Asked Questions

1. What is the average price of pure nickel bars?

Pure nickel bars such as Nickel 200 or Nickel 201 generally cost between $25 and $36 per KG, depending on size and surface finish.

2. How does Monel or Inconel bar pricing compare to pure nickel?

Monel 400 and Inconel 625 bars are more expensive than pure nickel due to the presence of additional alloying elements like copper, chromium, and molybdenum. Prices can range from $30 to $65 per KG.

3. Where can I find reliable nickel bar suppliers at competitive prices?

For competitive pricing, sourcing from Chinese and Indian manufacturers is advisable. However, for specialized or certified requirements, suppliers in the USA or Europe may be more suitable despite higher costs.