Nickel bar is a widely used semi-finished metal product, available in pure nickel grades (such as Nickel 200 and 201) and nickel alloys like Monel, Inconel, and Hastelloy. It serves diverse industries including electronics, aerospace, battery production, chemical processing, and marine engineering. In 2025, the price of nickel bar varies significantly depending on alloy type, size, purity, supplier region, and market volatility. This article provides a comprehensive analysis of current nickel bar prices, factors that influence costs, and tips for sourcing competitively worldwide.

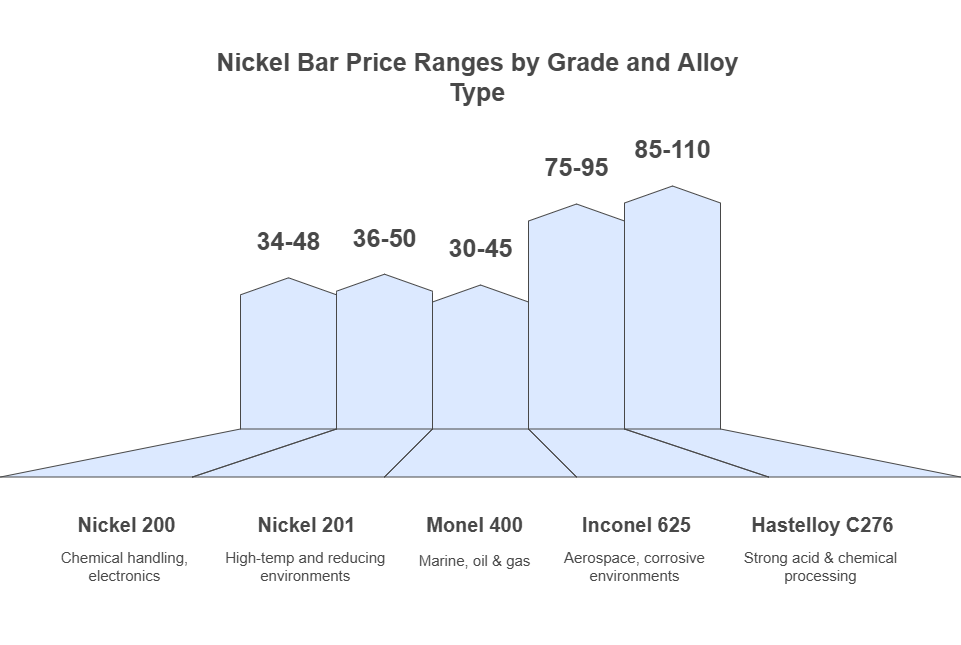

Nickel Bar Price by Grade and Alloy Type

| Nickel Grade | Purity (%) | Price Range (USD/kg) | Application |

|---|---|---|---|

| Nickel 200 | 99.6 | 34 – 48 | Chemical handling, electronics |

| Nickel 201 | 99.6 (low C) | 36 – 50 | High-temp and reducing environments |

| Monel 400 | ~67 Ni, 30 Cu | 30 – 45 | Marine, oil & gas |

| Inconel 625 | ~58 Ni + Cr/Mo | 75 – 95 | Aerospace, corrosive environments |

| Hastelloy C276 | ~57 Ni + Mo/W | 85 – 110 | Strong acid & chemical processing |

Nickel Bar Price by Size (Pure Nickel Grades)

| Diameter (mm) | Length (mm) | Price (USD/kg) | Notes |

|---|---|---|---|

| 10 – 20 | 1000 – 2000 | 36 – 48 | Used in machining & fasteners |

| 20 – 50 | 1000 – 3000 | 34 – 45 | General industrial use |

| 50 – 100 | Cut-to-length | 32 – 42 | Forging, toolmaking |

| 100+ | Custom | 30 – 38 | Bulk pricing applies |

Factors Affecting Nickel Bar Pricing

1. Nickel Spot Price: The base material cost is directly tied to global nickel markets. Price per kg rises with fluctuations in the London Metal Exchange (LME).

2. Alloy Content: Pure nickel bars (Nickel 200/201) cost less than high-performance alloys with added chromium, molybdenum, or iron.

3. Processing and Finish: Bars with polished, centerless ground, or turned finishes cost more than as-rolled or hot-formed bars.

4. Certification and Compliance: Material Test Certificates (MTC), ASTM compliance (e.g., B160, B166), and export documentation add marginal cost.

5. Order Size and Location: Larger orders get better unit pricing. Suppliers in China and India generally offer the lowest pricing for standard bars.

Regional Price Comparison (Nickel 200/201 Bars)

| Region | Price Range (USD/kg) | Remarks |

|---|---|---|

| China | 30 – 42 | Bulk supply, competitive pricing |

| India | 32 – 45 | Good for mid-range orders, certified supply |

| USA | 38 – 50 | Faster delivery, higher spec control |

| Europe | 40 – 55 | Premium quality, local compliance |

Tips for Sourcing Nickel Bars at the Best Price

• Specify exact alloy and tolerance in inquiries.

• Order standard lengths (e.g., 1000mm or 2000mm) to reduce cutting fees.

• Request MTC and compliance documents upfront.

• Compare FOB vs. CIF terms to understand full cost impact.

Related Questions and Answers

How much does pure nickel bar cost per kg in 2025?

Nickel 200 and 201 bars typically cost between USD 34 to 48 per kg, depending on size, finish, and supplier location.

Why is alloyed nickel more expensive than pure nickel?

Nickel alloys contain additional expensive elements like molybdenum or chromium and require more complex processing, which increases the overall cost.

Where is the best place to buy nickel bars in bulk?

China and India are top choices for bulk orders due to competitive pricing and extensive production capacity for nickel-based bars.