Nickel capillary tubing is a precision-engineered component widely used in industries such as chemical processing, aerospace, medical instrumentation, and power generation. Known for its excellent corrosion resistance, high-temperature stability, and mechanical strength, nickel tubing plays a crucial role in transferring fluids and gases under extreme conditions. Understanding the price structure of nickel capillary tubing helps businesses make informed purchasing decisions and optimize supply chain strategies. This article explores the key factors influencing its price, global market trends, and practical guidance for buyers.

Global Market Overview of Nickel Capillary Tubing

The nickel capillary tubing market has seen steady growth over the past decade, primarily driven by increasing demand for high-performance materials in harsh environments. Nickel and its alloys, such as Inconel and Monel, are favored for their superior durability and chemical resistance. The global demand is especially strong in sectors like oil and gas exploration, pharmaceuticals, and precision instrumentation. However, price volatility in nickel raw materials continues to affect overall tubing costs.

The following table shows approximate global market data for nickel capillary tubing:

| Region | Average Price (USD/kg) | Key Industries |

|---|---|---|

| North America | 45 – 60 | Aerospace, Medical, Oil & Gas |

| Europe | 50 – 65 | Chemical Processing, Energy, Research |

| Asia-Pacific | 40 – 55 | Electronics, Pharmaceuticals, Automotive |

| Middle East | 42 – 58 | Petrochemical, Industrial Engineering |

Factors Affecting Nickel Capillary Tubing Price

Several elements contribute to the fluctuating cost of nickel tubing. The most critical include:

| Factor | Impact on Price |

|---|---|

| Nickel Market Price | Nickel is a traded commodity, and its global price directly influences tubing costs. When nickel prices rise, so does tubing. |

| Alloy Composition | Tubing made from high-performance alloys (e.g., Inconel 625, Monel 400) costs more due to added elements like chromium or molybdenum. |

| Manufacturing Precision | Capillary tubes require tight tolerances, and precision machining or electro-polishing increases production costs. |

| Tube Size & Wall Thickness | Smaller diameters and thinner walls are more difficult to produce, increasing unit costs. |

| Quantity Ordered | Bulk orders usually reduce per-unit prices through economies of scale. |

| Geopolitical Events | Sanctions, mining restrictions, and transportation costs impact raw nickel supply and tubing availability. |

Nickel Capillary Tubing Price by Alloy Type

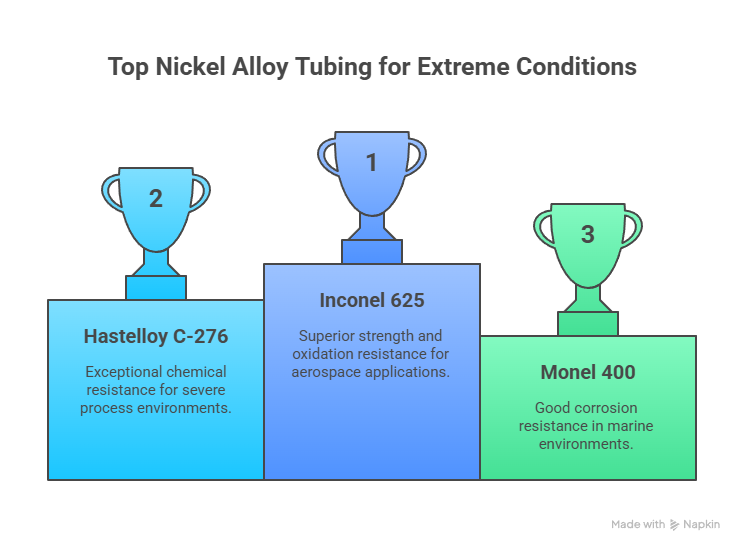

Different nickel alloys exhibit varying costs depending on their composition and performance characteristics. Below is a price comparison of common nickel alloy tubes:

| Nickel Alloy Type | Approx. Price Range (USD/kg) | Key Features |

|---|---|---|

| Nickel 200 / 201 | 35 – 50 | High purity, corrosion-resistant, used in electronic components |

| Inconel 600 | 45 – 65 | Excellent high-temperature resistance, suitable for heat exchangers |

| Inconel 625 | 60 – 85 | Superior strength, oxidation-resistant, ideal for aerospace applications |

| Monel 400 | 50 – 70 | Good corrosion resistance in marine environments |

| Hastelloy C-276 | 70 – 100 | Exceptional chemical resistance for severe process environments |

Applications Impacting Nickel Tubing Cost

The final price of nickel capillary tubing also depends on its intended use. High-end industries require customized specifications, additional testing, and certifications that raise costs. For instance:

| Application | Specification Requirement | Effect on Cost |

|---|---|---|

| Medical Devices | Ultra-clean surfaces, micro-diameter precision | High |

| Aerospace Systems | High-temperature tolerance, pressure resistance | Very High |

| Oil & Gas Exploration | Corrosion resistance to acidic fluids | Medium to High |

| Electronics Manufacturing | Thin wall, tight tolerances | Medium |

| Chemical Processing | High corrosion and oxidation resistance | Medium |

Market Trends and Price Forecast

As of recent years, nickel prices have experienced fluctuations due to increased demand for electric vehicle (EV) batteries and limited mining output. These factors indirectly influence the cost of nickel-based tubing. Industry analysts predict that nickel prices may continue to rise moderately through 2026, maintaining upward pressure on tubing costs.

Manufacturers are responding by improving production efficiency and adopting recycling strategies for nickel alloys to stabilize supply chains. The growing emphasis on sustainable materials sourcing and stricter quality standards is also reshaping pricing models across the global tubing market.

How to Choose the Right Supplier

Selecting the right supplier can significantly affect both cost and quality. Buyers should evaluate suppliers based on:

| Selection Criteria | Description |

|---|---|

| Quality Certifications | Look for ISO 9001, ASTM, or ASME compliance to ensure quality assurance. |

| Material Traceability | Ensure suppliers can provide complete documentation of material origin. |

| Customization Capability | Suppliers with flexible manufacturing processes can meet specialized dimensional needs. |

| Lead Time | Shorter delivery times often indicate efficient production systems. |

| After-Sales Support | Technical assistance and return policies improve overall value. |

Price Comparison: Nickel vs. Stainless Steel Capillary Tubing

Nickel tubing is generally mo