Nickel chrome wire suppliers provide high-quality resistance wires made from nickel and chromium alloys. These suppliers offer different grades such as NiCr 80/20, NiCr 70/30, and NiCr 60/15, suitable for heating elements, electrical resistors, and high-temperature applications. Below is an overview of major supplier categories, their strengths, and the types of nickel chrome wires they provide.

Main Categories of Nickel Chrome Wire Suppliers

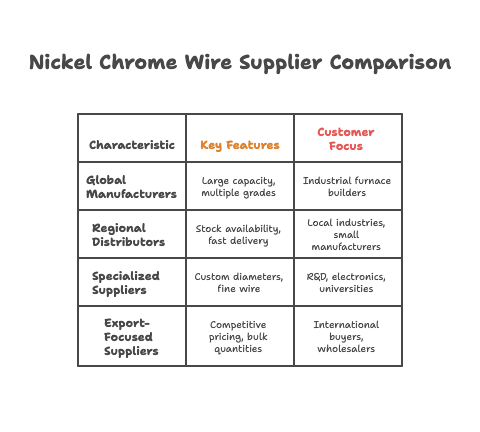

Nickel chrome wire suppliers can be divided into several categories based on their scale and specialty. Global manufacturers focus on large industrial demand, while smaller suppliers cater to specialized or custom requirements.

| Supplier Type | Key Features | Customer Focus |

|---|---|---|

| Global Manufacturers | Large production capacity, multiple alloy grades, international certifications | Industrial furnace builders, aerospace, automotive |

| Regional Distributors | Stock availability, fast delivery, multiple diameters in stock | Local industries, laboratories, small manufacturers |

| Specialized Suppliers | Custom diameters, fine wire, ribbon form, non-standard alloys | R&D, electronics, universities |

| Export-Focused Suppliers | Competitive pricing, bulk quantities, flexible MOQ | International buyers, wholesalers, importers |

Popular Grades Offered by Suppliers

Most nickel chrome wire suppliers provide standard and customized alloy grades. These grades are designed to meet diverse requirements, from household appliances to industrial furnaces.

| Grade | Composition | Applications |

|---|---|---|

| NiCr 80/20 | 80% Nickel, 20% Chromium | High-resistance heating elements, aerospace applications |

| NiCr 70/30 | 70% Nickel, 30% Chromium | High-temperature furnaces, oxidation-resistant systems |

| NiCr 60/15 | 60% Nickel, 15% Chromium, balance iron | General heating elements, appliances, cost-efficient uses |

| NiCr 35/20 | 35% Nickel, 20% Chromium, balance iron | Chemical processing, wire mesh, medium resistance applications |

Factors to Consider When Selecting a Supplier

Choosing the right nickel chrome wire supplier requires evaluation of technical, financial, and logistical aspects. Below is a simplified comparison of selection factors.

| Factor | Why It Matters |

|---|---|

| Alloy Purity | Ensures stable resistance and longer lifespan in high-temperature environments |

| Wire Diameter Range | Important for matching heating element design and electrical resistance values |

| MOQ (Minimum Order Quantity) | Small R&D projects may need low-quantity suppliers, while industry requires bulk |

| Certifications | Guarantees compliance with international standards such as ASTM or ISO |

| Lead Time | Crucial for production schedules and on-time project delivery |

Advantages of Working with Reliable Nickel Chrome Wire Suppliers

Reliable suppliers not only deliver high-quality wire but also provide technical support and customization options. Working with trusted suppliers ensures consistent performance, longer equipment lifespan, and reduced downtime in industrial operations.

| Advantage | Explanation |

|---|---|

| Product Consistency | Uniform resistivity and diameter across batches |

| Technical Support | Expert guidance for selecting grades and diameters |

| Customization | Suppliers can provide specific spool sizes, coatings, or wire forms |

| Supply Chain Reliability | Steady inventory ensures smooth production for customers |

Frequently Asked Questions

Q1: Who are the main nickel chrome wire suppliers?

Main suppliers include global manufacturers, regional distributors, and specialized producers offering standard and custom NiCr wires.

Q2: What grades of nickel chrome wire are most commonly supplied?

The most common grades are NiCr 80/20, NiCr 70/30, and NiCr 60/15, which are used for heating elements, resistors, and industrial furnaces.

Q3: How do I choose the right supplier?

Evaluate suppliers based on alloy purity, certifications, available sizes, pricing, lead time, and minimum order quantities that match your project needs.