Nickel chromium alloy wire is a highly versatile material widely used in industries such as electronics, heating, aerospace, and chemical processing. Known for its excellent resistance to oxidation, high tensile strength, and stable electrical resistance, this wire is often the first choice for applications that require durability in extreme temperatures. Below, we will explore the properties, applications, manufacturing standards, grades, and advantages of nickel chromium alloy wire in detail.

What is Nickel Chromium Alloy Wire?

Nickel chromium alloy wire is a type of resistance wire made by combining nickel and chromium in specific proportions. The most common alloy ratio is approximately 80% nickel and 20% chromium, but variations exist depending on performance requirements. This combination provides a balance of corrosion resistance, strength, and thermal stability, making it ideal for high-temperature environments.

Key Properties of Nickel Chromium Alloy Wire

The unique characteristics of nickel chromium alloy wire make it valuable in a wide range of applications. Its ability to resist oxidation at high temperatures is particularly important for heating elements and industrial furnaces.

| Property | Description |

|---|---|

| Melting Point | About 1400°C – 1450°C |

| Resistivity | 1.09 – 1.18 μΩ·m at 20°C |

| Maximum Operating Temperature | Up to 1200°C in air |

| Tensile Strength | High tensile strength even at elevated temperatures |

| Corrosion Resistance | Excellent resistance to oxidation and scaling |

| Thermal Expansion | Stable and predictable expansion with heat |

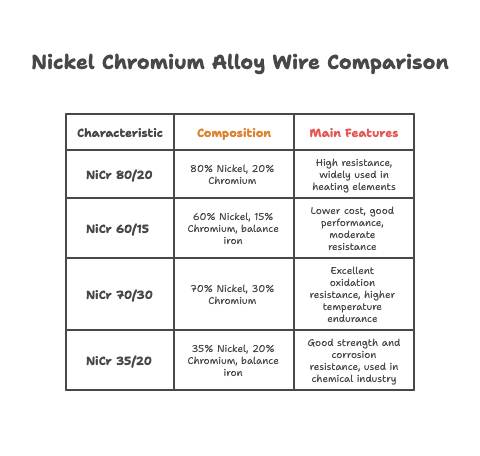

Common Grades of Nickel Chromium Alloy Wire

Different grades of nickel chromium alloy wire are available to meet various industrial demands. Each grade offers specific advantages depending on the application requirements.

| Grade | Composition | Main Features |

|---|---|---|

| NiCr 80/20 | 80% Nickel, 20% Chromium | High resistance, widely used in heating elements |

| NiCr 60/15 | 60% Nickel, 15% Chromium, balance iron | Lower cost, good performance, moderate resistance |

| NiCr 70/30 | 70% Nickel, 30% Chromium | Excellent oxidation resistance, higher temperature endurance |

| NiCr 35/20 | 35% Nickel, 20% Chromium, balance iron | Good strength and corrosion resistance, used in chemical industry |

Applications of Nickel Chromium Alloy Wire

The versatility of nickel chromium alloy wire makes it a core material in multiple sectors. It is most commonly used for resistance heating but also plays a role in electrical and chemical engineering.

| Industry | Application |

|---|---|

| Electronics | Resistors, thermocouples, circuit components |

| Heating | Toasters, ovens, industrial furnaces, kilns |

| Aerospace | Turbine engines, thermal insulation wire |

| Chemical Processing | Wire mesh, reactor elements, acid-resistant systems |

| Automotive | Glow plugs, heating coils, exhaust components |

Manufacturing Standards and Sizes

Nickel chromium alloy wire is produced under strict international standards to ensure consistent quality. Wires are available in multiple diameters, surface finishes, and spool types to match different requirements.

| Standard | Specification |

|---|---|

| ASTM B267 | Standard for resistance wire and strip |

| ISO 21927 | International specification for resistance alloys |

| DIN 17470 | German standard for nickel alloy resistance wires |

| GB/T 1234 | Chinese national standard for resistance wires |

Advantages of Nickel Chromium Alloy Wire

Nickel chromium alloy wire is favored over alternative materials like iron-chromium-aluminum alloys due to several unique benefits.

| Advantage | Explanation |

|---|---|

| High Temperature Strength | Maintains stability at temperatures above 1000°C |

| Oxidation Resistance | Forms a protective oxide layer that prevents scaling |

| Stable Electrical Resistance | Consistent performance in heating applications |

| Long Service Life | Durable under cyclic heating and cooling conditions |

| Ease of Fabrication | Good machinability and formability for custom shapes |

How to Select Nickel Chromium Alloy Wire

Selecting the right wire depends on temperature requirements, resistance value, and intended use. Engineers often compare grades, dimensions, and resistivity to find the best match. The tables above provide guidance, but consultation with suppliers ensures accurate specifications.

Frequently Asked Questions

Q1: What is nickel chromium alloy wire used for?

It is mainly used for heating elements, resistors, thermocouples, and high-temperature industrial equipment.

Q2: How long does nickel chromium alloy wire last?

The lifespan depends on operating conditions, but it typically offers a long service life due to its excellent resistance to oxidation and thermal fatigue.

Q3: Is nickel chromium alloy wire safe for household appliances?

Yes, it is widely used in appliances like ovens, toasters, and hair dryers because it is reliable, stable, and safe under controlled electrical loads.