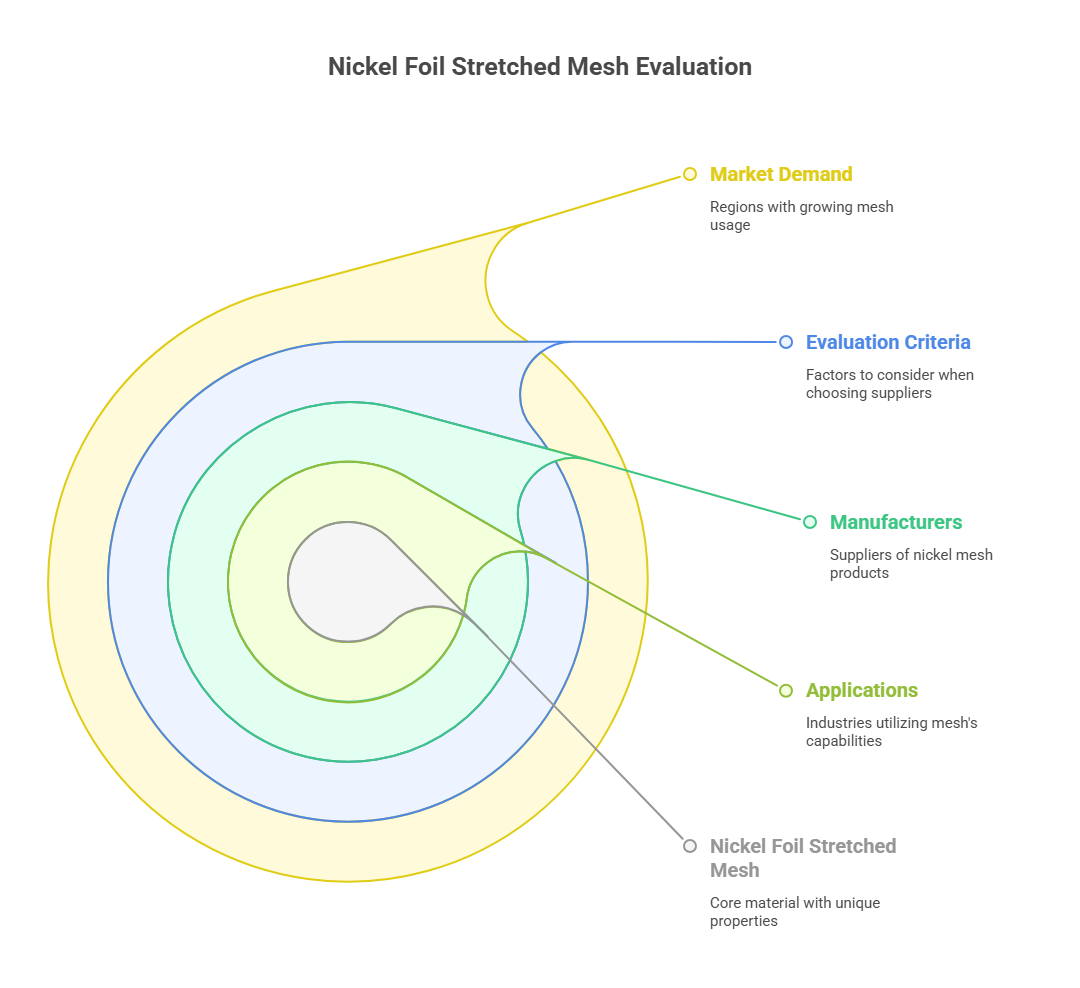

Nickel foil stretched mesh is a high-performance material created by mechanically expanding or etching thin nickel foil to form a mesh with uniform openings. This specialized mesh is widely used in applications requiring high conductivity, corrosion resistance, and structural stability, such as fuel cells, battery electrodes, EMI shielding, and catalytic layers. In 2025, the number of manufacturers offering nickel foil stretched mesh is steadily increasing, with several regions emerging as major production centers. This article explores leading global suppliers, their capabilities, and how to choose the right mesh for your application.

What is Nickel Foil Stretched Mesh?

Nickel foil stretched mesh is typically produced from pure nickel foil (≥99.5%) with thicknesses ranging from 0.01 mm to 0.1 mm. The mesh can be created through stretching (expanded metal) or precision etching to form uniform hexagonal or diamond-shaped holes. It is characterized by:

• Excellent thermal and electrical conductivity

• High corrosion resistance in alkaline and acidic environments

• Light weight and high surface-area-to-volume ratio

• Good flexibility and formability

Top Nickel Foil Stretched Mesh Manufacturers in 2025

| Company | Country | Min. Foil Thickness | Mesh Type | Key Applications |

|---|---|---|---|---|

| Xinxiang Dexing | China | 0.01 mm | Expanded, Etched | Fuel Cells, EMI Shielding |

| Precision Eforming | USA | 0.012 mm | Etched Mesh | Battery Electrodes, Sensors |

| Veco BV | Netherlands | 0.015 mm | Electroformed Mesh | Medical, Microfiltration |

| FoShan HongZe | China | 0.02 mm | Expanded Mesh | Catalytic Substrates |

| Tech-Etch Inc. | USA | 0.01 mm | Chemical Etched | Shielding Gaskets, Aerospace |

Specifications and Customization Options

| Parameter | Typical Range | Remarks |

|---|---|---|

| Foil Thickness | 0.01 mm – 0.1 mm | Thinner foils for batteries, thicker for shielding |

| Mesh Opening Size | 0.1 mm – 3.0 mm | Smaller openings offer more surface area |

| Opening Shape | Diamond, Hexagonal, Round | Defined by die or etching mask |

| Roll Width | ≤1000 mm | Customized based on project needs |

| Surface Finish | Annealed, Bright, Matte | Depends on downstream usage |

Common Applications of Nickel Foil Mesh

| Industry | Function | Mesh Characteristics |

|---|---|---|

| Fuel Cells | Gas Diffusion Layer (GDL) | High porosity, fine mesh |

| Battery Industry | Current Collector | Ultra-thin, corrosion-resistant |

| Electronics | EMI/RFI Shielding | Uniformity, conductivity |

| Chemical Processing | Catalyst Support | Thermal stability, chemical resistance |

How to Evaluate a Mesh Manufacturer

1. Tolerance Control: Top manufacturers maintain opening width tolerance within ±0.01 mm, critical for battery and fuel cell uniformity.

2. Quality Assurance: Look for ISO9001-certified factories that provide MTCs (Material Test Certificates) and dimensional reports.

3. Customization Capability: Ensure the supplier can customize mesh shape, thickness, and roll size for your specific requirements.

4. Export Experience: Companies with export history typically offer better packaging, documentation, and customer service.

Lead Time and MOQ by Supplier Type

| Supplier Type | Lead Time | MOQ |

|---|---|---|

| Large Manufacturer | 2–4 weeks | 10–50 m² |

| Custom Etching Factory | 3–7 days | 1 sheet or 1 roll |

| Online Distributors | 1–3 days | No MOQ |

Markets with Growing Demand in 2025

The following regions are experiencing the fastest growth in nickel mesh usage:

• Europe: Fuel cell and hydrogen-related R&D

• North America: Aerospace shielding and battery innovation

• Southeast Asia: EV component production and catalyst markets

Related Questions and Answers

What is the minimum thickness of nickel foil mesh available?

Leading manufacturers like Tech-Etch and Dexing can produce nickel foil stretched mesh as thin as 0.01 mm, ideal for energy storage and precision electronics.

What is the difference between etched mesh and expanded mesh?

Etched mesh is chemically or laser-cut from foil with precise patterns, offering high dimensional accuracy, while expanded mesh is mechanically stretched, more economical, but with less precision.

Where can I source nickel foil mesh with custom hole size?

Custom hole sizes can be ordered from manufacturers like Veco (Netherlands), Precision Eforming (USA), or Xinxiang Dexing (China), all of whom offer tailored mesh solutions based on technical drawings.