Nickel pipes—made from pure nickel or nickel-based alloys—are essential in demanding industrial applications, including chemical processing, marine systems, and heat exchangers. Their price per kilogram depends heavily on alloy type, manufacturing method, dimensions, certification standards, and location. This guide presents current price ranges, cost factors, and purchasing insights.

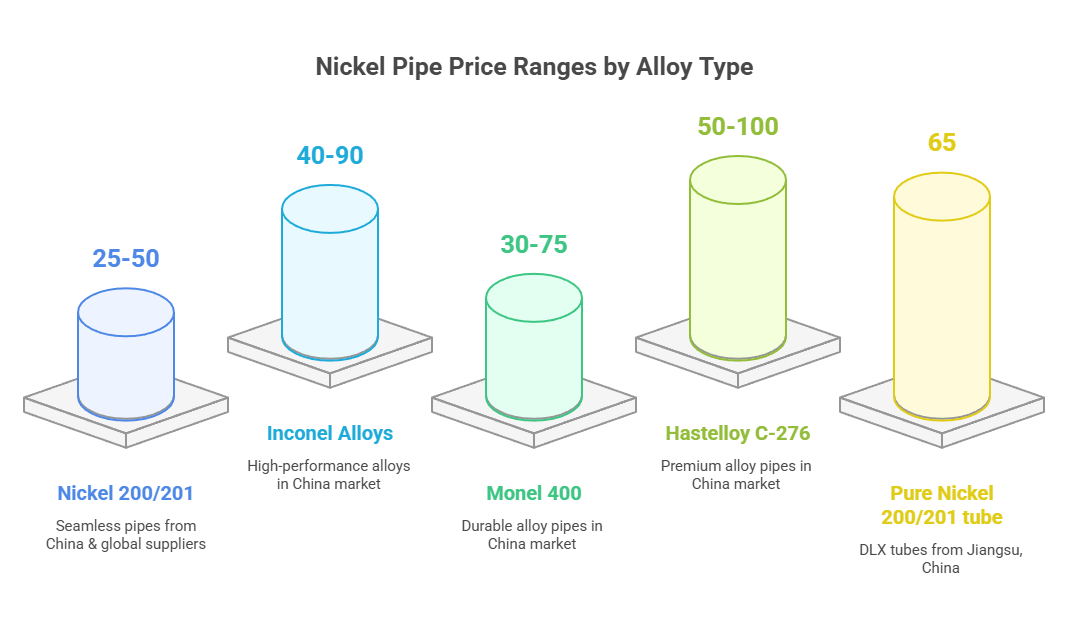

Current Nickel Pipe Price Ranges (USD/kg)

| Alloy / Type | Price Range | Region / Source |

|---|---|---|

| Nickel 200/201 (seamless) | $25–50 | China & global suppliers |

| Inconel alloys (600/625/718) | $40–90 | China market |

| Monel 400 | $30–75 | China market |

| Hastelloy C‑276 | $50–100 | China market |

| Pure Nickel 200/201 tube (DLX) | $65 | Jiangsu, China |

Market Nickel Reference Price

LME nickel spot prices averaged around $15,000–15,700/tonne (~$15–16/kg) in early 2025. However, finished pipe prices are significantly higher due to alloys, processing, and certification premiums.

Factors Affecting Nickel Pipe Price

| Factor | Impact on Price |

|---|---|

| Alloy Composition | Higher alloy content (Inconel, Monel, Hastelloy) increases cost |

| Manufacturing Method | Seamless > Welded due to complexity |

| Dimensions | Greater wall thickness/OD increases material costs |

| Certifications | Standards like ASTM, ASME, PED add testing/documentation costs |

| Raw Material Prices | Fluctuations in nickel LME price affect base cost ($15–16/kg) |

| Region & Logistics | China offers low base rates but add freight, duties for imports |

Cost Premiums Over Base Nickel Price

| Component | Estimated Premium ($/kg) |

|---|---|

| Processing (seamless, forming) | 10–25 |

| Heat treatment & testing | 5–15 |

| Certification & documentation | 2–10 |

| Profit margin & logistics | 3–20 |

| Total Premium | $20–70+ |

Buying Tips for Best Value

1. Choose alloy smartly: Stick to Nickel 200/201 for general use; pick Inconel/Monel/Hastelloy only when needed.

2. Compare seamless vs welded: Welded pipes may save 20–30% if seam integrity isn’t critical.

3. Order larger volumes: Bulk purchases (≥100 kg) often reduce per-kg overheads.

4. Get quotes from Chinese suppliers: Base prices lower ($25–50/kg), but include freight, tariffs.

5. Check certifications: Ensure compliance with ASTM, ASME, PED, NACE as required by your application.

6. Monitor LME nickel price: Time purchases when nickel base price dips (currently ~$15–16/kg)

Frequently Asked Questions

What is the typical price per kilogram for nickel 200 pipe?

Nickel 200/201 seamless pipe typically costs between **$25 and $50 per kg**, depending on size, quantity, and certifications

Why are Inconel, Monel, and Hastelloy pipes priced higher?

These higher-performance alloys include significant premiums due to alloying elements (Cr, Mo), specialized manufacturing for high integrity, testing, and certifications—typically bringing prices to **$30–100+/kg**

How much of the pipe price is due to base nickel metal?

With LME nickel trading around **$15–16/kg**, the balance of pipe price (often an extra **$20–70+ per kg**) stems from processing, certification, alloy premiums, and logistics