Nickel plate is a flat-rolled product made from pure nickel or nickel-based alloys, widely used in battery manufacturing, electronics, chemical processing, aerospace, and hydrogen energy applications. In 2025, the price of nickel plate is influenced by factors such as alloy composition, thickness, surface finish, certification, and global nickel market trends. This article offers a comprehensive overview of nickel plate pricing by type, size, supplier location, and buying tips for industrial users.

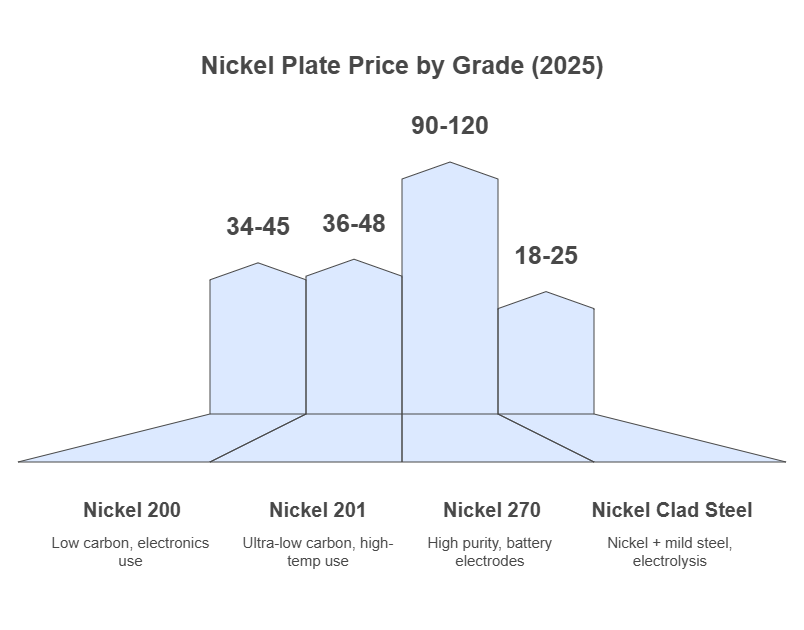

Nickel Plate Price by Grade (2025 Average, USD/kg)

| Grade | Purity / Alloy | Price Range (USD/kg) | Typical Applications |

|---|---|---|---|

| Nickel 200 | 99.6% Ni (low carbon) | 34 – 45 | Electronics, chemical tanks |

| Nickel 201 | 99.6% Ni (ultra-low carbon) | 36 – 48 | High-temp environments |

| Nickel 270 | ≥99.95% Ni | 90 – 120 | Battery electrodes, R&D |

| Nickel Clad Steel | Nickel + Mild Steel | 18 – 25 | Electrolysis, plating |

Nickel Plate Price by Thickness

| Thickness (mm) | Price Range (USD/kg) | Notes |

|---|---|---|

| 0.2 – 0.5 mm | 38 – 55 | Used in batteries, electronics |

| 0.5 – 1.5 mm | 36 – 50 | For shields, gaskets, tanks |

| 1.5 – 3.0 mm | 34 – 46 | Fabrication and structural use |

| 3.0 – 6.0 mm | 32 – 42 | Industrial plating bases |

Factors That Affect Nickel Plate Pricing

1. Purity and Grade: Higher purity (Nickel 270 or 99.99%) plates are priced significantly above industrial-grade (Nickel 200/201).

2. Thickness and Width: Thinner and wider plates generally cost more due to precision rolling and higher processing requirements.

3. Surface Finish: Bright annealed, mirror polished, or electroplated surfaces carry additional polishing and treatment costs.

4. Certification: ASTM B162, ISO 9001, REACH, and RoHS compliance increase cost but are essential for export or regulated sectors.

5. Supplier and Location: Chinese suppliers offer the most competitive rates, especially for high-volume standard orders.

Nickel Plate Price by Region

| Region | Standard Grade Price (USD/kg) | Notes |

|---|---|---|

| China | 30 – 42 | Most competitive, flexible MOQ |

| India | 32 – 45 | Strong in electroplating market |

| USA | 38 – 50 | Certifications and local delivery |

| Europe | 40 – 55 | Strict standards, aerospace qualified |

Standard Sizes and Price Impact

| Size (mm) | Standard Form | Price Impact |

|---|---|---|

| 100 x 100 x 0.5 | Cut sheet | +20–30% (cutting loss) |

| 1000 x 1000 x 1.0 | Mill sheet | Standard rate |

| 1200 x 2400 x 3.0 | Full plate | Bulk pricing (lower $/kg) |

Buying Tips for Nickel Plate

• Order standard sizes to reduce custom cutting fees.

• For battery or plating use, specify surface roughness and finish type.

• Request MTC and ASTM compliance before confirming order.

• Compare FOB vs. CIF prices to determine actual cost per kg delivered.

Related Questions and Answers

What is the current price of pure nickel plate per kg?

In 2025, pure nickel plate (Nickel 200/201) typically costs between USD 34 and 48 per kg depending on thickness, finish, and supplier.

Is there a price difference between Nickel 200 and 201 plate?

Yes, Nickel 201 is slightly more expensive than Nickel 200 (by 2–4 USD/kg on average) due to its lower carbon content and suitability for higher temperatures.

Where can I find the best price for nickel plate in bulk?

Chinese suppliers generally offer the best pricing for bulk orders, especially for standard sizes of Nickel 200 and 201 plates with common finishes.