Nickel Titanium alloy, commonly referred to as Nitinol (Nickel Titanium Naval Ordnance Laboratory), is a unique shape memory and superelastic alloy composed of roughly 55% nickel and 45% titanium. It is extensively used in biomedical devices, actuators, aerospace, robotics, and energy applications due to its ability to return to its original shape after deformation. In 2025, the price of Nickel Titanium alloy plate varies greatly based on grade, surface condition, purity, and supplier region. This guide provides a comprehensive breakdown of current market prices, influencing factors, and sourcing recommendations.

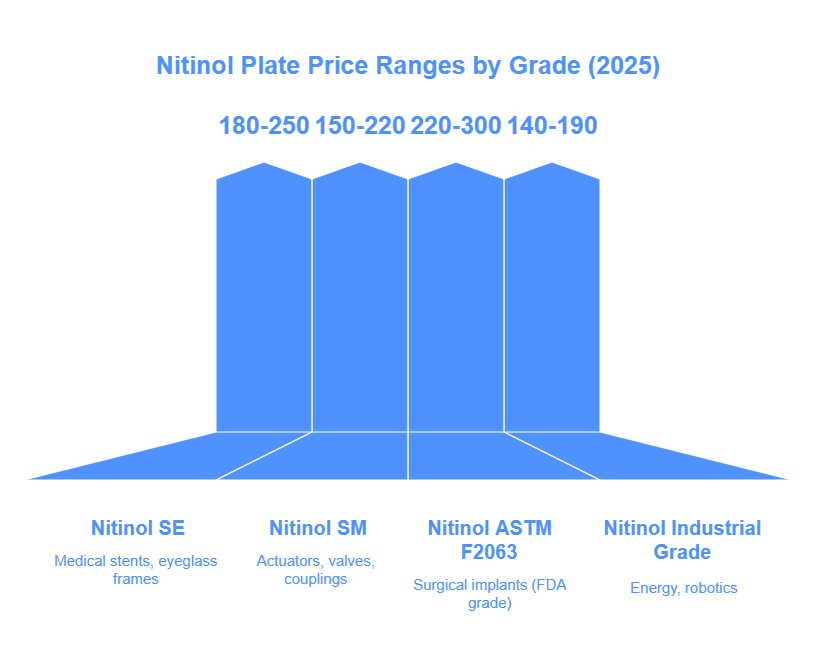

Nickel Titanium (Nitinol) Plate Price by Grade (USD/kg)

| Grade | Nickel Content (%) | Application Focus | Price Range (USD/kg) |

|---|---|---|---|

| Nitinol SE (Superelastic) | ≈ 55.8% | Medical stents, eyeglass frames | 180 – 250 |

| Nitinol SM (Shape Memory) | ≈ 50 – 55% | Actuators, valves, couplings | 150 – 220 |

| Nitinol ASTM F2063 | ≈ 55.8% | Surgical implants (FDA grade) | 220 – 300 |

| Nitinol Industrial Grade | ≈ 54 – 56% | Energy, robotics | 140 – 190 |

Nitinol Plate Price by Thickness (2025)

| Thickness (mm) | Standard Size (mm) | Price Range (USD/kg) | Common Usage |

|---|---|---|---|

| 0.3 – 0.5 | 100 x 100 | 200 – 280 | Orthodontic springs, research |

| 0.6 – 1.5 | 100 x 300 | 180 – 240 | Medical devices, actuators |

| 2.0 – 3.0 | 150 x 500 | 150 – 220 | Robotic arms, aerospace brackets |

| 3.0 – 5.0 | Custom | 140 – 200 | Energy storage, couplings |

Nickel Titanium Plate Price by Region (USD/kg)

| Region | Grade Availability | Average Price (USD/kg) | Remarks |

|---|---|---|---|

| China | SE, SM, Industrial | 140 – 210 | Best value for large-volume orders |

| USA | ASTM F2063, SE | 220 – 300 | Top choice for medical applications |

| Germany | SM, SE | 200 – 280 | High-precision R&D and surgical quality |

| India | SM, Industrial | 160 – 220 | Affordable source for engineering use |

Factors Affecting Nickel Titanium Plate Pricing

1. Purity and Grade: Medical-grade Nitinol costs significantly more due to stringent manufacturing and certification standards.

2. Plate Thickness: Ultra-thin plates require high-precision rolling, increasing costs per kg.

3. Heat Treatment: SE and SM grades are treated differently, impacting price depending on phase transformation temperature settings.

4. Testing & Certification: FDA-grade and ASTM F2063-compliant material includes chemical, tensile, and superelastic testing costs.

5. Supply Chain: Most raw Nitinol ingots are controlled by a few global producers, causing limited supply and higher pricing.

Estimated Price per Plate by Size (2025)

| Size (mm) | Thickness (mm) | Weight (kg) | Approx. Price (USD) |

|---|---|---|---|

| 100 x 100 | 0.3 | ≈ 0.24 kg | 48 – 70 |

| 100 x 300 | 1.0 | ≈ 2.4 kg | 420 – 600 |

| 150 x 500 | 2.0 | ≈ 12 kg | 1800 – 2600 |

Related Questions and Answers

How much does Nickel Titanium (Nitinol) alloy plate cost per kg in 2025?

The 2025 price of Nitinol plates ranges from USD 140 to 300 per kg depending on the grade, certification, and thickness.

Which Nitinol plate grade is used for medical implants?

ASTM F2063-grade superelastic Nitinol is the standard for surgical implants and stents due to its biocompatibility and high fatigue strength.

Where can I buy Nitinol plates at factory price?

China and India offer the most cost-effective Nitinol plates for industrial use, while the USA and Germany are best for certified medical and aerospace grades.