Nimonic 75 sheet is a nickel-chromium alloy with added titanium, widely manufactured in specialized factories. Known for its excellent oxidation resistance and high strength at elevated temperatures, Nimonic 75 sheets are commonly used in aerospace, furnace components, and industrial gas turbines. Factories producing Nimonic 75 sheets follow international standards such as ASTM B333 and AMS 5540, ensuring quality and consistency. Buyers can obtain sheets in hot rolled, cold rolled, or precision-cut forms directly from factories at competitive prices.

Chemical Composition of Nimonic 75 Sheet

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Bal. (72 min) |

| Chromium (Cr) | 18 – 21 |

| Titanium (Ti) | 0.2 – 0.5 |

| Iron (Fe) | 5.0 max |

| Copper (Cu) | 0.5 max |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Carbon (C) | 0.08 – 0.15 |

Mechanical Properties of Nimonic 75 Sheet

| Property | Value |

|---|---|

| Tensile Strength | ~ 780 MPa |

| Yield Strength (0.2% offset) | ~ 330 MPa |

| Elongation | ~ 40% |

| Density | 8.37 g/cm³ |

| Melting Range | 1380 – 1420 °C |

Available Specifications in Factories

| Standard | Specification |

|---|---|

| ASTM | B333 |

| AMS | 5540 |

| BS | 3075, 3076 |

| EN | 2.4951, 2.4630 |

Applications of Nimonic 75 Sheets

| Industry | Typical Uses |

|---|---|

| Aerospace | Turbine engine components, exhaust systems |

| Power Generation | Gas turbine combustion chambers |

| Industrial | Furnace fixtures, heat treatment equipment |

| Chemical Processing | Oxidizing environments, reactor linings |

| Automotive | High-temperature gaskets, exhaust parts |

Advantages of Buying from Nimonic 75 Sheet Factories

- Direct factory pricing for cost savings

- Custom thicknesses from 0.5 mm to 50 mm

- Surface finishes: 2B, BA, polished, or brushed

- Mill Test Certificates (MTC) available

- Packing for global exports with seaworthy standards

- Compliance with ASTM, AMS, and EN standards

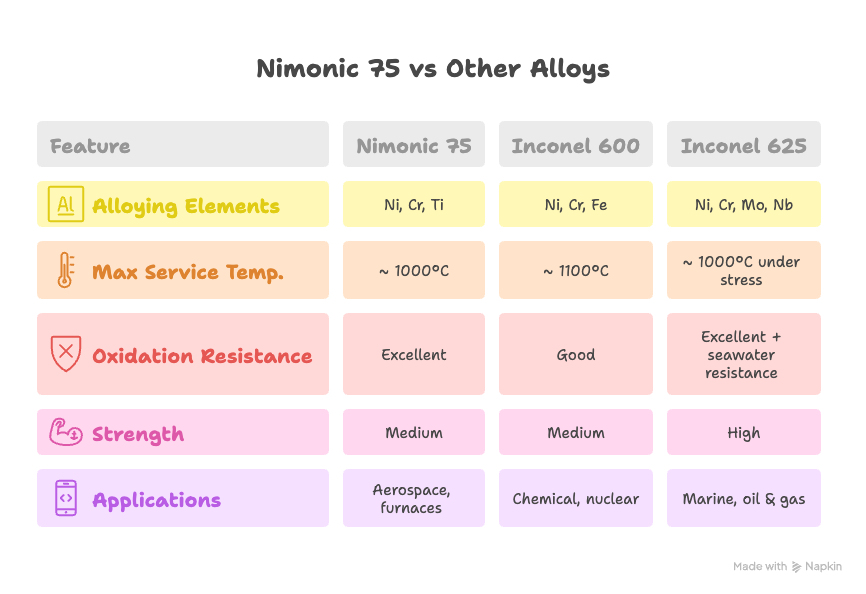

Nimonic 75 vs Other Nickel Alloys

| Feature | Nimonic 75 | Inconel 600 | Inconel 625 |

|---|---|---|---|

| Main Alloying Elements | Ni, Cr, Ti | Ni, Cr, Fe | Ni, Cr, Mo, Nb |

| Max Service Temp. | ~ 1000°C | ~ 1100°C | ~ 1000°C under stress |

| Oxidation Resistance | Excellent | Good | Excellent + seawater resistance |

| Strength | Medium | Medium | High |

| Applications | Aerospace, furnaces | Chemical, nuclear | Marine, oil & gas |

Related Questions and Answers

What is Nimonic 75 sheet used for?

Nimonic 75 sheet is commonly used in aerospace engines, industrial furnaces, gas turbines, and chemical processing equipment due to its high-temperature oxidation resistance.

Is Nimonic 75 the same as Inconel?

No. While both are nickel-based alloys, Nimonic 75 contains titanium and is optimized for oxidation resistance at high temperatures, whereas Inconel grades vary with chromium, molybdenum, and niobium for broader corrosion resistance.

Can factories supply custom-sized Nimonic 75 sheets?

Yes. Nimonic 75 sheet factories can provide custom lengths, widths, and thicknesses with different surface finishes according to customer requirements.