Nimonic 80A is a nickel-chromium alloy reinforced with titanium, aluminum, and carbon for excellent strength and creep resistance at high temperatures. Manufacturers of Nimonic 80A supply sheets, plates, bars, and forgings that meet international standards such as ASTM B637 and BS 3076. This alloy is widely used in aerospace, gas turbines, nuclear reactors, and high-temperature industrial applications. By working directly with a Nimonic 80A manufacturer, buyers can obtain reliable material certifications, consistent quality, and customized specifications at factory prices.

Chemical Composition of Nimonic 80A

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Bal. (69 min) |

| Chromium (Cr) | 18 – 21 |

| Titanium (Ti) | 2.0 – 2.7 |

| Aluminum (Al) | 1.0 – 1.8 |

| Carbon (C) | 0.06 – 0.15 |

| Cobalt (Co) | ≤ 2.0 |

| Iron (Fe) | ≤ 3.0 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

Mechanical Properties of Nimonic 80A

| Property | Value |

|---|---|

| Tensile Strength | ~ 1000 MPa |

| Yield Strength (0.2% offset) | ~ 600 MPa |

| Elongation | ~ 20% |

| Hardness | ~ 250 HB |

| Density | 8.19 g/cm³ |

| Melting Range | 1320 – 1365 °C |

Available Forms from Manufacturers

| Form | Thickness/Size Range |

|---|---|

| Sheets & Plates | 0.5 mm – 50 mm |

| Bars & Rods | Diameter 6 mm – 300 mm |

| Strips | Width 10 mm – 600 mm |

| Forgings | Custom shapes & dimensions |

| Wires | Diameter 0.1 mm – 10 mm |

Applications of Nimonic 80A

| Industry | Typical Applications |

|---|---|

| Aerospace | Turbine blades, discs, combustion chambers |

| Power Generation | Gas turbines, steam turbine components |

| Nuclear | Reactor components, fuel element parts |

| Industrial Heating | Furnace fixtures, heat treatment tools |

| Automotive | Exhaust valves, turbocharger parts |

Advantages of Working with Nimonic 80A Manufacturers

- Factory-direct pricing without middleman costs

- Supply of standardized and custom specifications

- Mill Test Certificates (MTC) with every shipment

- Heat treatment and surface finishing options

- Packaging suitable for global export logistics

- Compliance with ASTM, BS, EN, and AMS standards

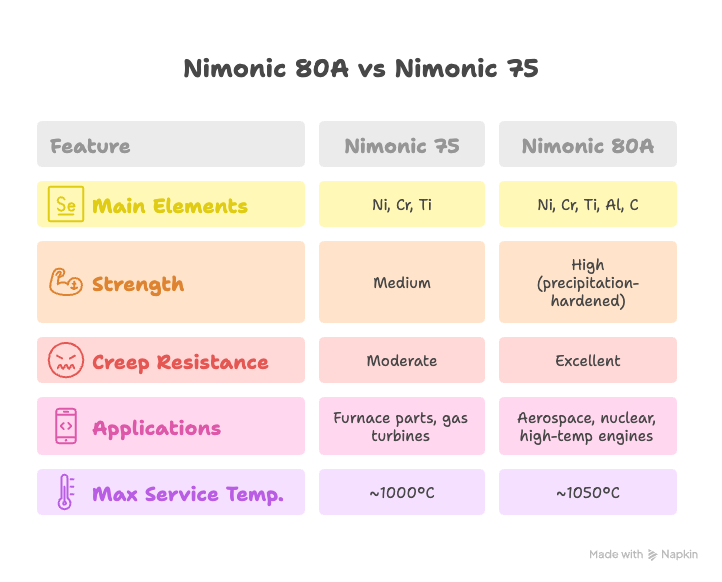

Nimonic 80A vs Nimonic 75

| Feature | Nimonic 75 | Nimonic 80A |

|---|---|---|

| Main Elements | Ni, Cr, Ti | Ni, Cr, Ti, Al, C |

| Strength | Medium | High (precipitation-hardened) |

| Creep Resistance | Moderate | Excellent |

| Applications | Furnace parts, gas turbines | Aerospace, nuclear, high-temp engines |

| Max Service Temp. | ~1000°C | ~1050°C |

Related Questions and Answers

What is Nimonic 80A mainly used for?

Nimonic 80A is primarily used in aerospace turbine engines, nuclear reactors, gas turbines, and high-temperature furnace parts due to its excellent creep and oxidation resistance.

How is Nimonic 80A different from Nimonic 75?

Nimonic 80A contains aluminum and higher titanium compared to Nimonic 75, giving it superior precipitation hardening, higher strength, and better creep resistance at elevated temperatures.

Can manufacturers provide custom Nimonic 80A dimensions?

Yes. Nimonic 80A manufacturers can supply custom sheet sizes, bar lengths, forged components, and wire diameters based on specific customer requirements.