Nimonic 80A, a nickel-based superalloy known for its exceptional high-temperature strength and oxidation resistance, is widely used in aerospace, gas turbines, and automotive components. Understanding the price of Nimonic 80A involves analyzing market demand, raw material costs, alloying elements, manufacturing processes, and geopolitical influences. This article provides a comprehensive breakdown of the current and historical pricing of Nimonic 80A with insights for buyers and industry professionals.

What is Nimonic 80A and Why Is It Valuable?

Nimonic 80A is a precipitation-hardened nickel-chromium alloy containing titanium and aluminum. It is engineered to withstand high-temperature environments and is primarily used in turbine blades, exhaust valves, and high-performance fasteners. Due to its performance characteristics, it commands a premium price in the alloy market.

Factors Affecting Nimonic 80A Price

Several factors contribute to the price fluctuations of Nimonic 80A, including:

| Factor | Description | Impact on Price |

|---|---|---|

| Nickel Market Price | Nickel is the base element, and its global price has a direct impact on Nimonic 80A costs. | High impact |

| Chromium Availability | Chromium is essential for corrosion resistance; scarcity raises alloy prices. | Moderate to High |

| Manufacturing Cost | Includes energy, labor, and processing technologies like vacuum induction melting. | Moderate |

| Demand in Aerospace | Increased aerospace production raises demand, affecting prices. | High |

| Geopolitical Factors | Export/import duties, sanctions, and supply chain disruptions. | Variable |

Current Price Range of Nimonic 80A (2025)

The current price of Nimonic 80A in mid-2025 varies based on form, supplier, and quantity. Below is a breakdown of typical market rates:

| Product Form | Average Price (USD/kg) | Notes |

|---|---|---|

| Rod | $80 – $110 | Used in turbine shafts, available in multiple diameters |

| Sheet/Plate | $90 – $120 | Used in aerospace structural parts |

| Wire | $100 – $130 | High demand in fasteners and springs |

| Custom Forgings | $150+ | Depends on specifications and quantity |

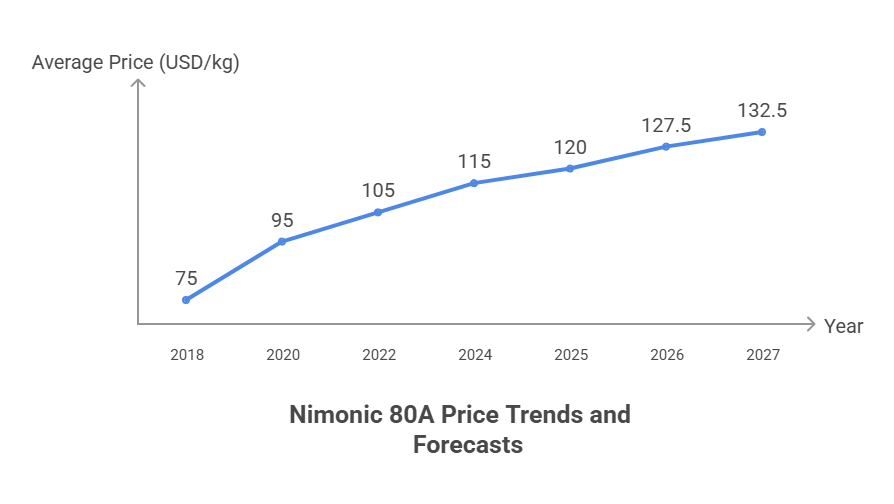

Price Trends and Historical Data

Nimonic 80A has seen significant price shifts in the past decade, primarily influenced by nickel market volatility. Below is a simplified overview of average historical prices.

| Year | Average Price (USD/kg) | Remarks |

|---|---|---|

| 2018 | $75 | Stable supply and moderate demand |

| 2020 | $95 | Pandemic disrupted supply chain |

| 2022 | $105 | Nickel prices surged |

| 2024 | $115 | Aerospace rebound post-COVID |

How to Source Nimonic 80A at Competitive Prices

Procurement strategies can significantly affect the final cost of Nimonic 80A. Tips include:

- Bulk Purchasing: Large orders reduce per-unit costs.

- Global Sourcing: Compare suppliers across regions.

- Direct from Manufacturer: Eliminates middlemen markup.

- Spot vs Contract Pricing: Long-term contracts may offer price stability.

Top Global Suppliers of Nimonic 80A

Here are some of the top international suppliers known for Nimonic 80A production and export:

| Company | Country | Specialty |

|---|---|---|

| Special Metals | USA | Original developer of Nimonic alloys |

| VDM Metals | Germany | High-performance alloys |

| Allegheny Technologies Inc. (ATI) | USA | Advanced materials and alloy solutions |

| Yingkou Join Special Alloys | China | Competitive pricing for Asia-Pacific market |

Forecast for Nimonic 80A Prices (2025–2027)

While future prices can never be guaranteed, industry forecasts predict modest increases in Nimonic 80A pricing due to sustained demand in aerospace and renewable energy sectors. Nickel price stabilization and new supply chain efficiencies may help moderate sharp increases.

| Year | Expected Price Range (USD/kg) | Market Conditions |

|---|---|---|

| 2025 | $110 – $130 | High demand, strong aerospace sector |

| 2026 | $115 – $140 | Nickel market pressure |

| 2027 | $120 – $145 | Stabilized supply chains |

Regional Price Differences

Pricing can also vary based on location due to tariffs, shipping, and local supply chain factors.

| Region | Typical Price Range (USD/kg) | Comment |

|---|---|---|

| North America | $110 – $130 | High aerospace consumption |

| Europe | $115 – $135 | Environmental regulations raise costs |

| Asia | $90 – $120 | Local production reduces prices |

| Middle East | $95 – $125 | Growing aerospace investment |

FAQs About Nimonic 80A Price

1. Why is Nimonic 80A more expensive than other nickel alloys?

Nimonic 80A is more costly due to its precise chemical composition, rigorous production methods like vacuum induction melting, and its capability to withstand extreme temperatures, making it ideal for aerospace applications.

2. Where can I buy Nimonic 80A at the best price?

The most competitive pricing is often available directly from alloy manufacturers or global distributors in Asia. Online platforms such as Alibaba and engineering metals suppliers also provide competitive quotes for bulk orders.

3. How has the price of Nimonic 80A changed over the years?

The price has generally trended upwards due to increased demand in high-performance industries, with occasional drops during periods of lower nickel prices or global slowdowns like the COVID-19 pandemic.