Nimonic 80A round bars are manufactured in specialized factories for use in high-temperature and high-stress environments. This nickel-chromium alloy is strengthened with titanium, aluminum, and carbon, offering exceptional creep resistance and mechanical strength at elevated temperatures. Factories producing Nimonic 80A round bars provide them in hot rolled, forged, and precision ground conditions, complying with standards such as ASTM B637, AMS 5829, and BS 3076. Buyers benefit from factory-direct prices, reliable quality, and customized solutions for aerospace, power generation, and industrial applications.

Chemical Composition of Nimonic 80A Round Bars

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Bal. (69 min) |

| Chromium (Cr) | 18 – 21 |

| Titanium (Ti) | 2.0 – 2.7 |

| Aluminum (Al) | 1.0 – 1.8 |

| Carbon (C) | 0.06 – 0.15 |

| Cobalt (Co) | ≤ 2.0 |

| Iron (Fe) | ≤ 3.0 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | ≤ 0.2 |

Mechanical Properties of Nimonic 80A Round Bars

| Property | Value |

|---|---|

| Tensile Strength | ~ 1000 MPa |

| Yield Strength (0.2% offset) | ~ 600 MPa |

| Elongation | ~ 20% |

| Hardness | ~ 250 HB |

| Density | 8.19 g/cm³ |

| Melting Range | 1320 – 1365 °C |

Available Sizes from Factories

| Type | Diameter Range | Length |

|---|---|---|

| Hot Rolled Round Bars | 20 mm – 300 mm | Up to 6000 mm |

| Forged Round Bars | 50 mm – 500 mm | Custom sizes available |

| Bright & Polished Bars | 6 mm – 150 mm | Standard 3m / 6m |

| Ground Precision Bars | 6 mm – 80 mm | Cut to size |

Applications of Nimonic 80A Round Bars

| Industry | Uses |

|---|---|

| Aerospace | Turbine blades, discs, shafts |

| Power Generation | Gas turbine rotors, steam turbine parts |

| Nuclear | Reactor hardware, fuel assembly components |

| Automotive | Exhaust valves, turbocharger shafts |

| Industrial Heating | Furnace spindles, tooling bars |

Advantages of Buying Direct from Nimonic 80A Round Bar Factories

- Factory-direct pricing with no distributor markup

- Wide stock availability in hot rolled, forged, and bright bars

- Mill Test Certificates (MTC) according to EN 10204 3.1 / 3.2

- Custom machining and cut-to-size options

- Compliance with ASTM B637, AMS 5829, BS 3076 standards

- Export-ready packaging for global shipments

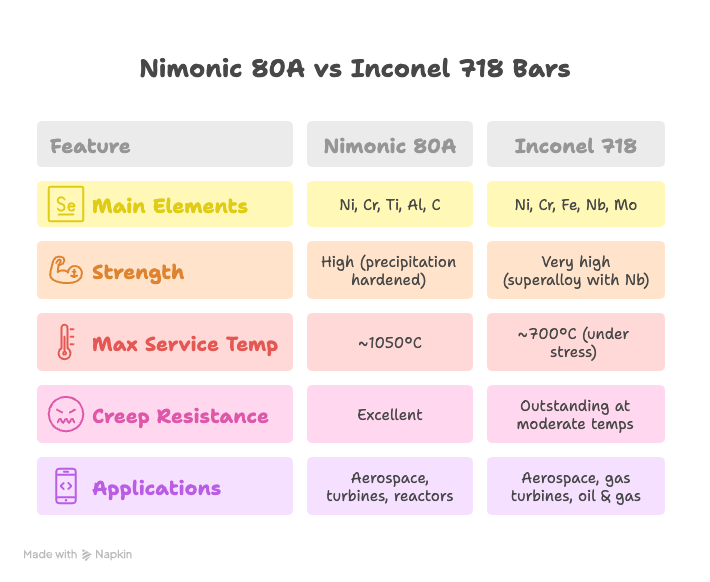

Nimonic 80A Round Bars vs Inconel 718 Bars

| Feature | Nimonic 80A | Inconel 718 |

|---|---|---|

| Main Elements | Ni, Cr, Ti, Al, C | Ni, Cr, Fe, Nb, Mo |

| Strength | High (precipitation hardened) | Very high (superalloy with Nb) |

| Max Service Temp. | ~1050°C | ~700°C (under stress) |

| Creep Resistance | Excellent | Outstanding at moderate temps |

| Applications | Aerospace, turbines, reactors | Aerospace, gas turbines, oil & gas |

Related Questions and Answers

What sizes of Nimonic 80A round bars are available from factories?

Factories supply Nimonic 80A round bars from 6 mm up to 500 mm in diameter, with lengths up to 6 meters or custom cut-to-size according to requirements.

Why is Nimonic 80A preferred in aerospace round bars?

Nimonic 80A offers excellent creep resistance, high strength, and oxidation resistance at temperatures up to 1050°C, making it ideal for turbine blades and engine parts.

Do factories provide certificates with Nimonic 80A round bars?

Yes. Factories issue Mill Test Certificates (MTC) as per EN 10204 3.1/3.2 to verify chemical composition and mechanical properties of Nimonic 80A round bars.