Nimonic 90 is a high-performance superalloy with exceptional resistance to high temperatures, oxidation, and corrosion, making it a preferred material in industries such as aerospace, power generation, and marine engineering. The demand for Nimonic 90 sheets, specifically, arises from the need for thin, durable, and heat-resistant materials used in critical applications like turbine components and exhaust systems. This article provides an overview of Nimonic 90 sheet factories, their manufacturing processes, and what to expect when sourcing sheets from these specialized facilities.

What is Nimonic 90 Sheet?

Nimonic 90 sheet is a flat, thin piece of the Nimonic 90 alloy, typically produced in various thicknesses ranging from 1mm to 50mm. This material is primarily used for applications where precision machining, heat resistance, and corrosion resistance are essential. Nimonic 90 sheets are used in high-performance parts that need to withstand extreme temperatures, such as in turbines, aerospace engines, and exhaust systems.

Manufacturing Process of Nimonic 90 Sheets

The production of Nimonic 90 sheets involves several stages, starting from the melting of the raw materials to the final rolling process. Below is a simplified breakdown of the manufacturing process:

| Step | Process Description |

|---|---|

| 1. Raw Material Melting | High-purity nickel and alloying elements like chromium, cobalt, and iron are melted together in an electric arc furnace to form the base Nimonic 90 alloy. |

| 2. Casting | The molten metal is poured into molds and cooled to form ingots, which are the raw material for sheet production. |

| 3. Hot Rolling | The ingots are heated to high temperatures and then passed through rollers to reduce the thickness and shape them into sheets of varying thickness. |

| 4. Cold Rolling | To achieve the desired thickness and finish, the hot-rolled sheets undergo a cold rolling process where they are further reduced and smoothed. |

| 5. Heat Treatment | The sheets are heat-treated to enhance their mechanical properties, such as strength and fatigue resistance. |

| 6. Cutting & Finishing | The final sheets are cut to the required dimensions, and additional finishing processes such as polishing or coating may be applied. |

Factors to Consider When Choosing a Nimonic 90 Sheet Factory

When selecting a factory to purchase Nimonic 90 sheets, several factors should be considered to ensure you receive high-quality material for your application:

| Factor | Importance |

|---|---|

| Material Quality | The factory should ensure high purity of raw materials and strict quality control during the manufacturing process to meet industry standards. |

| Custom Sizing | Some applications may require custom sheet dimensions or tolerances, so it’s important that the factory can accommodate specific requests. |

| Lead Time | Depending on the urgency of your order, the lead time for production and delivery can be a critical factor. Ensure the factory can meet your timeline. |

| Price | While price should not be the only consideration, it’s essential to compare prices from different manufacturers to ensure competitive rates for your required quantities. |

| Certifications | Ensure the factory has the necessary certifications (such as ISO or AS9100) to comply with industry standards, particularly for aerospace or power generation applications. |

Leading Nimonic 90 Sheet Manufacturers and Suppliers

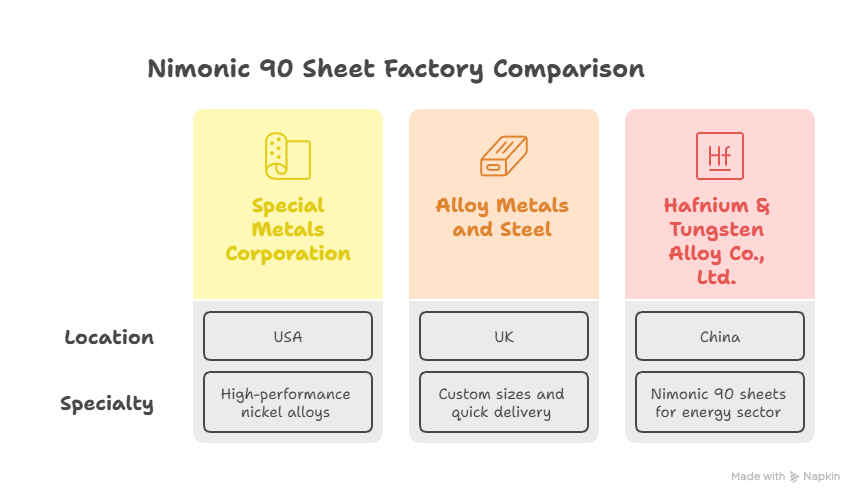

Some of the most well-known manufacturers and suppliers of Nimonic 90 sheets include:

| Manufacturer | Location | Specialty |

|---|---|---|

| Special Metals Corporation | USA | Supplier of high-performance nickel alloys for aerospace and industrial applications |

| Alloy Metals and Steel | UK | Manufacturer of Nimonic 90 sheets with a focus on custom sizes and quick delivery |

| Hafnium & Tungsten Alloy Co., Ltd. | China | Specializes in providing Nimonic 90 sheets to the energy sector, particularly for turbines |

Cost of Nimonic 90 Sheets from Factories

The price of Nimonic 90 sheets can vary depending on the thickness, quantity, and customization requirements. Generally, you can expect the following price range:

| Sheet Thickness | Price Range (per kilogram) |

|---|---|

| 1mm – 5mm | $100 – $150 |

| 5mm – 10mm | $120 – $160 |

| 10mm – 25mm | $130 – $180 |

| 25mm – 50mm | $150 – $200 |

Why Buy Nimonic 90 Sheets from a Factory?

Purchasing Nimonic 90 sheets directly from a manufacturer or factory ensures that you receive high-quality material produced under strict quality control measures. Factories have the capability to produce large quantities of custom-sized sheets, and they often offer competitive pricing for bulk orders. Direct purchase from a factory also allows you to ensure material traceability, which is critical for industries like aerospace, where strict certification requirements are in place.

Related Questions:

Where can I buy Nimonic 90 sheets?

You can purchase Nimonic 90 sheets directly from specialized alloy manufacturers and suppliers. Some well-known companies like Special Metals Corporation and Alloy Metals & Steel provide these materials to various industries.

What are the advantages of Nimonic 90 sheets?

Nimonic 90 sheets offer high strength, excellent oxidation resistance, and superior performance at elevated temperatures, making them ideal for turbine blades, combustion chambers, and other critical applications.

How much do Nimonic 90 sheets cost?

The price of Nimonic 90 sheets varies depending on thickness, size, and quantity. On average, prices range from $100 to $200 per kilogram, depending on the specific sheet specifications and order volume.