Nimonic and Inconel are both high-performance, nickel-based superalloys engineered to perform under extreme temperatures and stress. They are widely used in aerospace, power generation, and chemical industries. Although they share some similarities, they differ in composition, mechanical properties, corrosion resistance, and price. This article offers a detailed comparison of Nimonic vs Inconel to help engineers, buyers, and designers choose the most suitable material for their applications.

Overview of Nimonic and Inconel

Nimonic and Inconel are families of alloys rather than single materials. Each family includes several grades tailored for specific purposes. Below is a general overview:

| Alloy Family | Base Elements | Typical Use Cases |

|---|---|---|

| Nimonic | Nickel, Chromium, Titanium, Aluminum | Turbine blades, exhaust valves, springs |

| Inconel | Nickel, Chromium, Iron, Molybdenum | Heat exchangers, jet engines, marine applications |

Chemical Composition Comparison

While both alloy families contain nickel and chromium, their additional elements influence performance. Here’s a comparison between two popular grades: Nimonic 80A and Inconel 718.

| Element | Nimonic 80A (%) | Inconel 718 (%) |

|---|---|---|

| Nickel (Ni) | 76.0 | 50–55 |

| Chromium (Cr) | 19–21 | 17–21 |

| Titanium (Ti) | 1.8–2.7 | 0.65–1.15 |

| Aluminum (Al) | 1.0–1.8 | 0.2–0.8 |

| Molybdenum (Mo) | — | 2.8–3.3 |

| Iron (Fe) | <1 | Balance |

Mechanical Properties

Mechanical performance under high temperatures is critical in aerospace and energy sectors. Below is a performance comparison:

| Property | Nimonic 80A | Inconel 718 |

|---|---|---|

| Max Operating Temperature | 815°C | 700°C |

| Tensile Strength (MPa) | 960 | 1240 |

| Yield Strength (MPa) | 760 | 1030 |

| Hardness (Rockwell B) | 88 | 100 |

| Elongation (%) | 20 | 12 |

Corrosion Resistance

Inconel alloys are generally superior in corrosion resistance, particularly in marine and chemical environments. This makes Inconel ideal for offshore and acidic conditions. Nimonic, on the other hand, is designed more for high-temperature stability than corrosive environments.

Applications Comparison

The following table outlines typical uses of Nimonic and Inconel alloys:

| Industry | Nimonic | Inconel |

|---|---|---|

| Aerospace | Turbine blades, jet engine parts | Exhaust ducts, afterburners |

| Automotive | Exhaust valves, turbocharger parts | Manifolds, EGR components |

| Oil & Gas | — | Subsea equipment, piping |

| Power Generation | Steam turbine blades | Heat exchangers |

| Marine | — | Propeller shafts, seawater valves |

Weldability and Machinability

Inconel 718 has better weldability due to its iron content and balanced structure, making it easier to join using TIG and MIG processes. Nimonic alloys, being harder, can be more difficult to machine and weld without cracking unless properly preheated and post-heat-treated.

Cost Comparison

Pricing depends on grade, form, and supplier. In general, Inconel is more expensive due to its broader resistance capabilities and usage versatility.

| Form | Nimonic 80A (USD/kg) | Inconel 718 (USD/kg) |

|---|---|---|

| Rod | $80 – $110 | $90 – $130 |

| Sheet | $90 – $120 | $100 – $140 |

| Wire | $100 – $130 | $120 – $160 |

Selection Guide

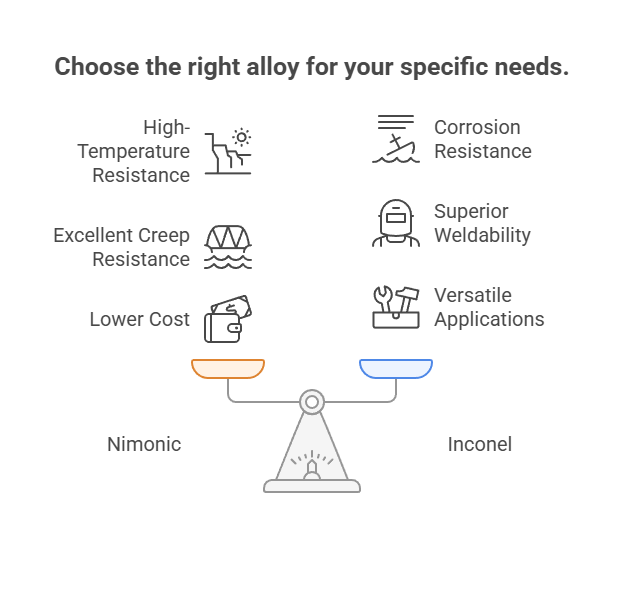

Use this guide to determine which alloy may suit your needs better:

| Requirement | Preferred Alloy | Reason |

|---|---|---|

| High-temperature fatigue resistance | Nimonic | Excellent creep resistance |

| Corrosion in seawater or acids | Inconel | Superior corrosion resistance |

| General weldability | Inconel | More forgiving for welding operations |

| Extreme aerospace performance | Nimonic | Trusted for high-performance turbine parts |

FAQs About Nimonic vs Inconel

1. What is the main difference between Nimonic and Inconel?

Nimonic is optimized for high-temperature strength and creep resistance, whereas Inconel offers broader corrosion resistance and better overall mechanical properties, especially in harsh chemical or marine environments.

2. Is Inconel stronger than Nimonic?

In general, Inconel alloys like 718 have higher tensile and yield strength than most Nimonic grades, making them better suited for structural applications requiring high strength and corrosion resistance.

3. Which is more expensive: Nimonic or Inconel?

Inconel is typically more expensive due to its versatility and superior corrosion resistance, though specific pricing depends on the alloy grade and form.