Nitronic 60 is a high-performance austenitic stainless steel alloy known for its superior resistance to wear, galling, and corrosion. Commonly used in demanding applications like pump components, valves, and marine hardware, Nitronic 60 stands out for its ability to retain strength and durability even in extreme environments. For buyers and engineers, identifying reliable Nitronic 60 suppliers is critical to ensuring performance, certification compliance, and cost-effectiveness. This comprehensive guide outlines key suppliers, technical details, and procurement tips.

What is Nitronic 60?

Nitronic 60 (UNS S21800) is an austenitic stainless steel alloy strengthened by nitrogen and high manganese content. It is engineered to resist galling, fretting, and wear, and provides strong corrosion resistance comparable to 304 and 316 stainless steels.

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 17.0 – 20.0 |

| Manganese (Mn) | 7.0 – 9.0 |

| Nickel (Ni) | 8.0 – 9.0 |

| Silicon (Si) | 3.5 – 4.5 |

| Nitrogen (N) | 0.08 – 0.18 |

| Carbon (C) | ≤ 0.10 |

Leading Nitronic 60 Suppliers

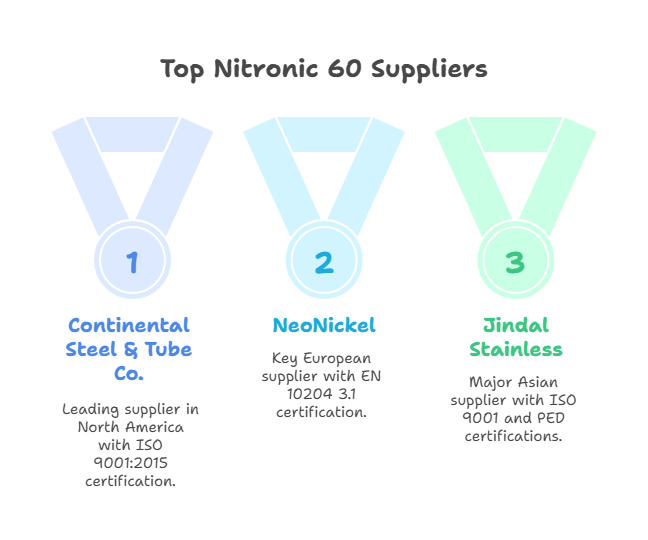

The following companies are recognized for their consistent supply of Nitronic 60 alloy in various forms and grades:

| Supplier | Region | Product Forms | Certifications |

|---|---|---|---|

| Continental Steel & Tube Co. | USA | Bar, Plate, Sheet | ISO 9001:2015 |

| NeoNickel | UK / EU | Round Bar, Plate | EN 10204 3.1 |

| Jindal Stainless | India | Sheet, Coil | ISO 9001, PED |

| Magellan Metals | USA | Rod, Tube, Fittings | DFARS Compliant |

| Special Metals Inc. | Canada | Wire, Forgings | AS9100, NADCAP |

Key Factors to Evaluate When Choosing a Supplier

When sourcing Nitronic 60, buyers must consider quality, logistics, and certification compliance:

| Criteria | Why It Matters | Best Practice |

|---|---|---|

| Certifications | Ensures traceability and standards compliance | Request ISO 9001, MTRs, and ASTM conformance |

| Product Form Availability | Different uses require different shapes | Check stock for bar, plate, sheet, tube |

| Minimum Order Quantity (MOQ) | Some projects require small quantities | Look for suppliers with low MOQ |

| Shipping & Logistics | Delays impact project timelines | Ask for estimated lead times and carriers |

Product Forms and Recommended Applications

Choosing the correct form of Nitronic 60 depends on its application. Below is a guide for optimal selection:

| Application | Recommended Form | Example Supplier |

|---|---|---|

| Fasteners and Bolts | Round Bar | NeoNickel |

| Pump Shafts | Rod | Magellan Metals |

| Wear Plates | Plate | Continental Steel |

| Valves and Seats | Forgings | Special Metals Inc. |

Global Availability by Region

Many suppliers operate globally, but availability and lead times may vary:

| Region | Common Suppliers | Lead Time Estimate |

|---|---|---|

| North America | Magellan Metals, Continental Steel | 1–2 weeks |

| Europe | NeoNickel, Thyssenkrupp | 2–3 weeks |

| Asia | Jindal Stainless, POSCO | 2–4 weeks |

| Middle East | Regional Distributors | 3–5 weeks |

Ordering Tips and Quote Requests

To get accurate pricing and ensure timely delivery, follow this process when contacting a supplier:

| Step | Action | Notes |

|---|---|---|

| 1 | Define Specs | Include dimensions, standards (ASTM A240, A276) |

| 2 | Choose Product Form | Specify shape: plate, rod, bar, etc. |

| 3 | State Quantity | Indicate exact weight or unit count |

| 4 | Include Shipping Info | Destination address helps estimate costs |

| 5 | Ask for Docs | Request MTRs and quality certificates |

Common Uses by Industry

Nitronic 60 is used in several critical sectors. Here’s how it adds value in each:

| Industry | Component | Material Benefit |

|---|---|---|

| Oil & Gas | Valve Stems | Excellent sulfide stress resistance |

| Marine | Bolts and Anchors | Corrosion resistance in seawater |

| Food Equipment | Hoppers, Conveyors | Non-toxic, FDA-compliant surfaces |

| Aerospace | Bearings and Fasteners | High strength-to-weight ratio |

Frequently Asked Questions

1. Where can I find verified Nitronic 60 suppliers?

Verified suppliers include Continental Steel (USA), NeoNickel (Europe), and Jindal Stainless (Asia). These companies provide MTRs and conform to ASTM and ISO certifications.

2. What forms does Nitronic 60 typically come in?

Common forms include round bar, flat bar, rod, wire, sheet, plate, tubing, and forgings. The form should match the intended application for optimal performance.

3. Do suppliers offer Nitronic 60 in custom sizes?

Yes, most suppliers provide cutting services or stock various diameters and thicknesses. Custom lengths and machined parts are also available upon request.