Rene 41 is a high-performance nickel-based superalloy known for its excellent mechanical properties, oxidation resistance, and high-temperature performance. This alloy is particularly suitable for turbine blades, high-stress applications, and aerospace components. Due to its outstanding ability to perform in extreme environments, Rene 41 bars are in high demand across various industries, including aerospace, power generation, and chemical processing. In this article, we will explore Rene 41 bars, the key factors affecting their price, and the best suppliers for these materials.

What is Rene 41?

Rene 41 is a nickel-based superalloy primarily designed for high-temperature applications. It offers a combination of superior strength, excellent oxidation resistance, and high creep resistance, making it ideal for parts that are subjected to extreme stress at elevated temperatures. Typically, it is used in gas turbines, aerospace applications, and other components that need to withstand continuous high-stress conditions.

Applications of Rene 41 Bars

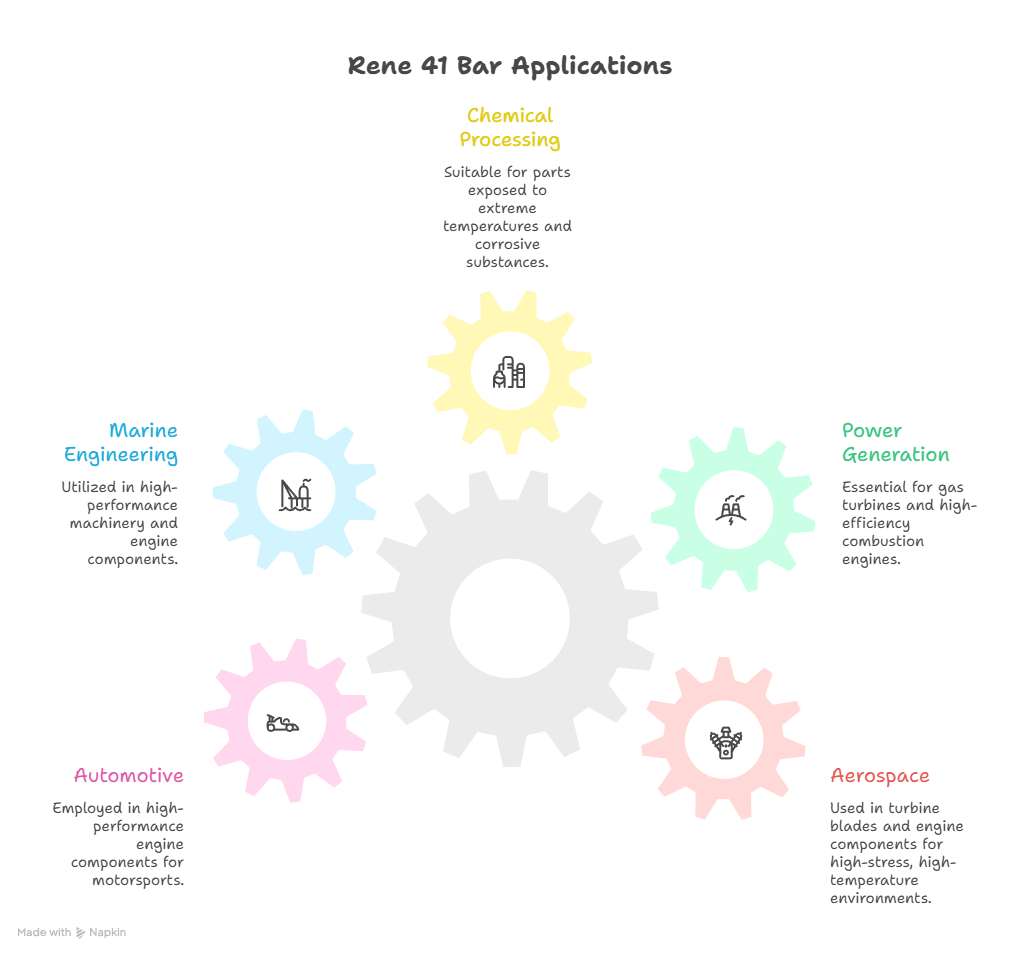

Rene 41 bars are commonly used in applications where high temperature and high-stress conditions prevail. Some typical applications include:

- Aerospace: Turbine blades, engine components, and exhaust systems

- Power Generation: Gas turbines and high-efficiency combustion engines

- Chemical Processing: Parts exposed to extreme temperatures and corrosive environments

- Marine Engineering: Components for engines and other high-performance machinery

- Automotive: High-performance engine components in motorsports

Factors Affecting Rene 41 Bar Price

The price of Rene 41 bars can vary based on several factors. When evaluating suppliers and prices, it’s important to consider the following elements:

| Factor | Impact on Price |

|---|---|

| Size and Diameter | The larger the diameter and size of the bar, the more material is required, resulting in higher production costs and pricing. Custom diameters or oversized bars typically carry a premium. |

| Length | The longer the bar, the more raw material and processing time are needed, thus increasing the cost. |

| Quantity | Ordering in bulk often leads to price reductions per unit, while smaller orders tend to have higher prices per kilogram. |

| Supplier’s Location | International shipping and import duties can add to the price, while local suppliers may offer more affordable delivery options. |

| Certifications | Rene 41 bars with certifications like ASTM, AMS, or ASME, or those that require additional testing, generally cost more due to the extra quality assurance processes involved. |

| Market Conditions | The price of raw materials, such as nickel and chromium, directly influences the overall price of Rene 41 bars. Volatility in the global metals market can lead to fluctuations in the cost of bars. |

| Fabrication and Processing | If your project requires special machining, surface treatments, or custom cutting, the price will increase due to the labor and equipment costs associated with these services. |

Why Choose Rene 41 Bars?

Rene 41 bars offer numerous advantages for industries that require components capable of withstanding extreme conditions. Some of the key benefits of choosing Rene 41 bars include:

- High Strength: Rene 41 offers exceptional tensile strength, allowing it to perform in high-stress environments.

- Oxidation Resistance: It maintains its integrity in the presence of oxygen at high temperatures, making it ideal for parts exposed to heat and oxidation.

- Creep Resistance: The material is engineered to resist deformation over time, even when exposed to continuous high temperatures.

- Corrosion Resistance: Rene 41 has good resistance to various corrosive environments, which is critical for components in harsh conditions.

- Long Service Life: Its durability and high performance ensure long-lasting components with minimal degradation over time.

Popular Rene 41 Bar Suppliers

There are several reputable suppliers that offer Rene 41 bars. When choosing a supplier, it’s important to consider factors such as material quality, certifications, customer service, and delivery timelines. Here are some of the leading suppliers:

- Ncalloys: Ncalloys is a leading supplier of high-performance alloys, including Rene 41 bars. They provide a wide range of sizes and custom lengths, and all materials come with full certifications. For a quote, contact [email protected].

- Special Metals: Special Metals is one of the top suppliers of Rene 41 bars. Known for their high-quality materials and extensive expertise in the nickel-based alloy industry, they provide a wide variety of sizes and grades.

- Haynes International: Haynes specializes in producing high-performance alloys such as Rene 41. They offer materials for high-temperature applications, including bars, sheets, and other products, with full quality assurance and certification.

- Rolled Alloys: Rolled Alloys provides Rene 41 bars in various sizes, with a focus on quick delivery and excellent customer service. They specialize in supplying high-temperature alloys to industries like aerospace and power generation.

- Future Metals: A well-established supplier of Rene 41 bars, Future Metals offers fast delivery times, custom lengths, and full material traceability to meet industry standards for aerospace and other high-performance applications.

Why Choose Ncalloys for Rene 41 Bars?

Ncalloys offers high-quality Rene 41 bars with exceptional mechanical properties and excellent resistance to high-temperature environments. We provide a range of sizes, from standard dimensions to custom orders, ensuring we meet the unique requirements of your project. Our Rene 41 bars come with full certifications, offering you confidence in the material’s quality and performance. Whether you’re in aerospace, power generation, or another high-performance industry, Ncalloys can supply the Rene 41 bars you need at competitive prices.

Manufacturer: Ncalloys

Contact Email: [email protected]

Related Questions

1. What is the composition of Rene 41 alloy?

Rene 41 is primarily composed of nickel (around 60%), chromium (around 20%), and other elements such as molybdenum, cobalt, and titanium, which contribute to its excellent high-temperature performance and oxidation resistance.

2. Can Rene 41 bars be welded?

Yes, Rene 41 bars can be welded using conventional methods. However, specialized techniques may be required to avoid cracking or other issues, particularly for high-stress or high-temperature applications.

3. What industries use Rene 41 bars?

Rene 41 bars are widely used in the aerospace, power generation, chemical processing, and automotive industries. They are commonly used in turbine blades, gas engines, furnace parts, and high-performance engine components due to their strength and resistance to high temperatures.