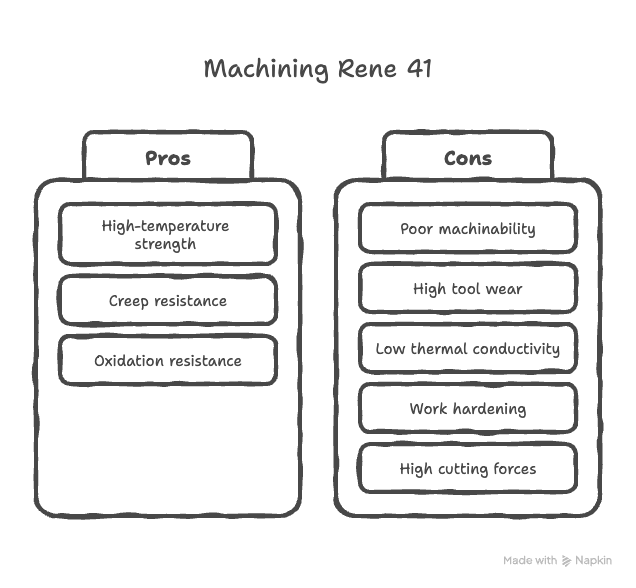

Rene 41 is a precipitation-hardened nickel-based superalloy known for its exceptional high-temperature strength, creep resistance, and oxidation resistance. While these properties make Rene 41 ideal for aerospace and high-performance industrial applications, they also make the alloy notoriously difficult to machine. Understanding Rene 41 machinability is critical for manufacturers aiming to achieve precision, surface quality, and tool life.

What Is Rene 41?

Rene 41 is a nickel-chromium-cobalt alloy strengthened by precipitation hardening, typically using aluminum and titanium. It is designed to maintain excellent mechanical strength at temperatures up to approximately 980°C (1800°F). Because of this, Rene 41 is commonly used in jet engine components, exhaust systems, afterburner parts, and high-temperature fasteners.

Overall Machinability of Rene 41

Rene 41 has poor machinability compared to carbon steel and stainless steel. It is generally considered more difficult to machine than Inconel 718 and similar nickel alloys. The main reasons include high hardness, strong work-hardening behavior, and low thermal conductivity.

Why Rene 41 Is Difficult to Machine

High Strength at Elevated Temperatures: Rene 41 retains its strength even when cutting temperatures rise, increasing cutting forces and tool wear.

Severe Work Hardening: The material hardens rapidly when plastically deformed, which can cause excessive tool wear if cutting passes are too light.

Low Thermal Conductivity: Heat generated during machining concentrates at the cutting edge rather than dissipating through the material, accelerating tool degradation.

Abrasive Carbide Phases: Hard precipitates within the alloy increase abrasion on cutting tools.

Machinability Rating

On a relative machinability scale where free-machining steel is rated at 100%, Rene 41 typically rates below 20%. This places it among the most difficult nickel-based superalloys to machine.

Recommended Machining Conditions

Successful machining of Rene 41 requires optimized parameters and rigid setups.

Cutting Speed: Low cutting speeds are essential. Typical turning speeds range from 10 to 25 m/min depending on tooling and operation.

Feed Rate: Moderate to heavy feeds are recommended to avoid rubbing and excessive work hardening.

Depth of Cut: Maintain sufficient depth of cut to stay below the hardened surface layer created by previous passes.

Tooling Recommendations

Tool Materials: Carbide tools with wear-resistant coatings such as TiAlN or AlTiN are commonly used. Ceramic tools may be applied for roughing at higher speeds under controlled conditions.

Tool Geometry: Positive rake angles help reduce cutting forces, while strong cutting edges are necessary to resist chipping.

Tool Wear Monitoring: Frequent inspection is essential, as tool failure can occur suddenly due to heat buildup.

Cooling and Lubrication

Effective cooling is critical when machining Rene 41. High-pressure coolant systems help reduce cutting temperature and flush chips away from the cutting zone. Flood cooling is generally preferred, while dry machining is not recommended for most operations.

Machining After Heat Treatment

Rene 41 is typically solution-treated and aged to achieve maximum strength. Machining is significantly easier in the solution-treated condition before aging. Whenever possible, rough machining should be performed prior to final heat treatment, with only light finishing cuts applied afterward.

Best Practices for Machining Rene 41

– Use rigid machine setups to minimize vibration

– Avoid dwell time during cutting to reduce work hardening

– Replace tools proactively rather than waiting for failure

– Use sharp tools and consistent cutting parameters

– Plan machining sequences to minimize heat buildup

Typical Applications Requiring Machining

Despite machining challenges, Rene 41 is widely used where performance outweighs manufacturing difficulty:

Aerospace: Turbine cases, exhaust components, afterburner parts

Industrial: High-temperature fasteners, heat shields, combustion hardware

Related Questions

Is Rene 41 harder to machine than Inconel 718?

Yes, Rene 41 is generally more difficult to machine due to higher strength at elevated temperatures and more aggressive work hardening.

Can Rene 41 be machined after aging?

It can be machined after aging, but tool wear is significantly higher. Rough machining is best done before final heat treatment.

What tools are best for machining Rene 41?

Coated carbide tools are most commonly used, with ceramic tools suitable for specific roughing operations under controlled conditions.