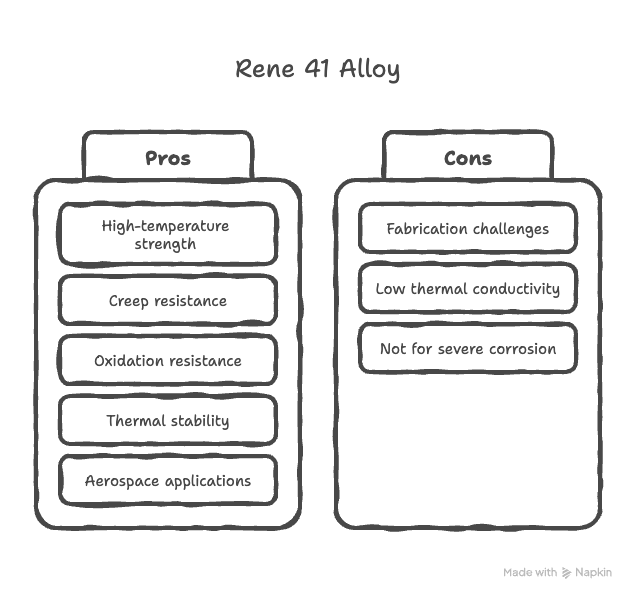

Rene 41 is a precipitation-hardened nickel-based superalloy developed for extreme high-temperature and high-stress environments. It is well known for its excellent creep resistance, high tensile strength, and oxidation resistance at elevated temperatures. Because of these properties, Rene 41 is widely used in aerospace and industrial applications where long-term stability and reliability are critical.

What Is Rene 41?

Rene 41 is a nickel-chromium-cobalt alloy strengthened primarily by aluminum and titanium precipitation. It is designed to maintain mechanical strength and structural integrity at temperatures up to approximately 980°C (1800°F). Rene 41 is typically supplied in solution-treated and aged conditions to achieve optimal performance.

Chemical Composition of Rene 41

The balanced chemical composition of Rene 41 provides a combination of high-temperature strength and oxidation resistance.

| Element | Typical Content (%) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 18–20 |

| Cobalt (Co) | 10–12 |

| Molybdenum (Mo) | 9–10.5 |

| Aluminum (Al) | 1.4–1.8 |

| Titanium (Ti) | 2.8–3.3 |

| Carbon (C) | 0.03–0.09 |

| Boron (B) | ≤ 0.01 |

Mechanical Properties of Rene 41

Rene 41 exhibits outstanding mechanical properties, especially at elevated temperatures, making it suitable for critical load-bearing components.

| Property | Typical Value |

|---|---|

| Tensile Strength (Room Temperature) | ≈ 1400–1550 MPa |

| Yield Strength | ≈ 1000–1200 MPa |

| Elongation | ≈ 10–20% |

| Hardness | ≈ 35–45 HRC |

| Creep Resistance | Excellent up to 980°C |

High-Temperature Performance

One of the defining material properties of Rene 41 is its ability to retain strength at elevated temperatures. The precipitation-hardened microstructure provides excellent resistance to creep and stress rupture, making the alloy suitable for long-term exposure to high heat and mechanical loads.

Oxidation and Corrosion Resistance

Rene 41 offers good oxidation resistance in high-temperature air environments due to its chromium content. It performs well in hot gas and combustion environments, although it is generally not intended for severe aqueous corrosion conditions when compared to alloys like Hastelloy.

Thermal Stability

The alloy remains structurally stable during prolonged exposure to elevated temperatures. Its resistance to phase instability and grain boundary degradation contributes to reliable performance in aerospace engine environments.

Physical Properties

| Property | Value |

|---|---|

| Density | ≈ 8.3 g/cm³ |

| Melting Range | ≈ 1320–1360°C |

| Thermal Conductivity | Low |

| Magnetic Properties | Non-magnetic |

Heat Treatment Characteristics

Rene 41 is typically solution heat treated followed by aging to develop its precipitation-hardened structure. Proper heat treatment is essential to achieve the desired balance of strength, ductility, and creep resistance.

Fabrication Characteristics

While Rene 41 offers exceptional material properties, it is challenging to fabricate. It exhibits strong work-hardening behavior and low thermal conductivity, which complicates machining and forming operations. Fabrication is usually performed prior to final aging treatment.

Typical Applications of Rene 41

The superior material properties of Rene 41 make it suitable for demanding applications:

Aerospace: Jet engine exhaust systems, afterburner components, turbine casings

Industrial: High-temperature fasteners, heat shields, combustion hardware

Defense: Missile and propulsion system components

Related Questions

What makes Rene 41 suitable for high-temperature applications?

Its precipitation-hardened structure provides excellent creep resistance and strength retention at temperatures up to 980°C.

Is Rene 41 corrosion resistant?

Rene 41 offers good oxidation resistance at high temperatures but is not primarily designed for severe aqueous corrosion environments.

Is Rene 41 stronger than Inconel 718?

Rene 41 generally offers superior high-temperature strength and creep resistance compared to Inconel 718, especially above 700°C.