Rene 41 (UNS N07041 / W.Nr 2.4973) is a high-performance nickel-chromium-cobalt superalloy known for its exceptional mechanical strength, excellent oxidation resistance, and stability at elevated temperatures. It is widely used in aerospace, power generation, and other industries requiring high-temperature durability. Suppliers provide Rene 41 sheets suitable for turbine components, combustion chamber liners, high-temperature structural parts, and specialized fasteners.

What Is Rene 41?

Rene 41 is a precipitation-hardenable nickel-based superalloy designed for critical high-temperature applications. Its high strength and resistance to oxidation and creep make it ideal for turbine blades, exhaust valves, and other components that operate under extreme conditions.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 14–16 |

| Cobalt (Co) | 19–21 |

| Molybdenum (Mo) | 2.2–2.8 |

| Titanium (Ti) | 1.3–1.7 |

| Aluminum (Al) | 1.3–1.7 |

| Iron (Fe) | ≤3 |

| Carbon (C) | ≤0.1 |

| Silicon (Si) | ≤0.5 |

| Manganese (Mn) | ≤0.5 |

Physical and Mechanical Properties

| Property | Value |

|---|---|

| Density | 8.38 g/cm³ |

| Melting Range | 1325–1380°C |

| Tensile Strength | 950–1050 MPa |

| Yield Strength | 700–750 MPa |

| Elongation | 12–18% |

| Hardness | 320–350 HB |

| Maximum Working Temperature | 980°C |

Applications of Rene 41 Sheet

| Industry | Application |

|---|---|

| Aerospace | Turbine blades, compressor discs, combustion chamber liners |

| Power Generation | Gas turbine components, heat exchangers, high-temperature structural parts |

| Automotive | Exhaust system components, turbocharger parts |

| Industrial Equipment | Furnace components, springs, high-temperature fasteners |

Common Sheet Forms and Sizes

| Thickness | Width | Length | Finish |

|---|---|---|---|

| 0.5–10 mm | 100–1500 mm | 1000–3000 mm | Bright, polished, pickled |

| 10–50 mm | 500–2000 mm | 2000–6000 mm | Hot-rolled, annealed, pickled |

Factors Affecting Pricing

| Factor | Impact |

|---|---|

| Thickness and dimensions | Thicker or larger sheets cost more due to higher material content |

| Heat treatment and processing | Fully solution-treated and age-hardened sheets are more expensive |

| Certification | Sheets with mill test certificates and traceability have higher cost |

| Quantity | Larger orders reduce price per kilogram |

| Market fluctuation | Nickel and cobalt price changes affect overall cost |

| Custom size or finish | Non-standard dimensions or finishes increase price |

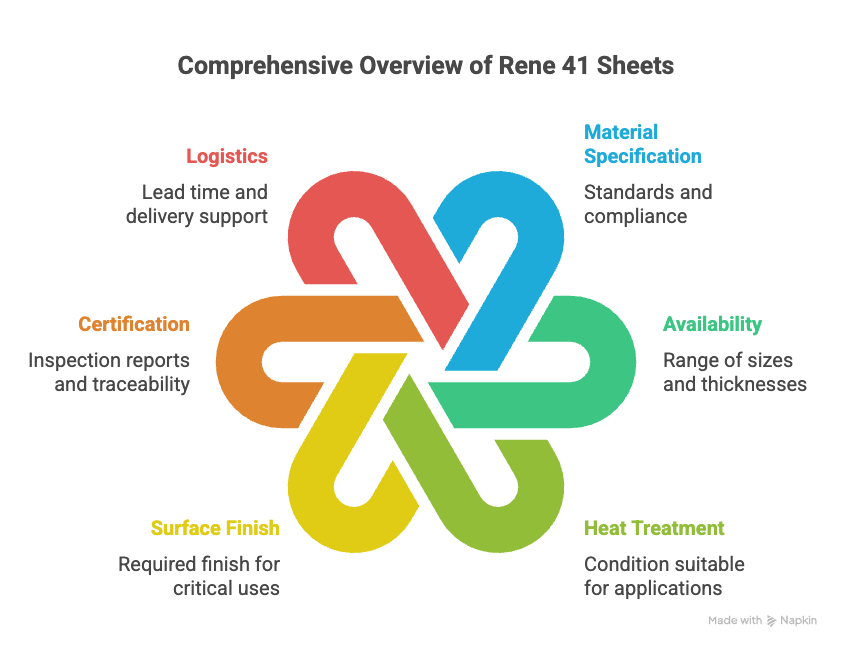

Choosing a Rene 41 Sheet Supplier

To select a reliable Rene 41 sheet supplier, consider the following:

- Material specification (UNS N07041 / W.Nr 2.4973) and compliance with AMS or equivalent standards

- Availability of required sheet thickness, width, and length

- Heat treatment condition (solution + age) suitable for your application

- Surface finish and straightness as required for critical applications

- Supplier’s ability to provide inspection reports and traceable mill test certificates

- Lead time, minimum order quantity (MOQ), and logistics support for delivery

Pricing Overview

| Sheet Thickness | Approximate Price (USD/kg) |

|---|---|

| 0.5–10 mm | 55–75 |

| 10–20 mm | 60–80 |

| 20–50 mm | 65–85 |

Related Questions

1. What is the typical specification for Rene 41 sheets?

Rene 41 sheets are commonly supplied to UNS N07041 / W.Nr 2.4973 and often conform to AMS 5545 or equivalent specifications.

2. Can Rene 41 sheets be custom cut?

Yes, many suppliers offer custom cut-to-size sheets, including guillotining, shearing, or prefabrication services to meet exact dimensions.

3. Is Rene 41 sheet suitable for high-temperature structural parts?

Yes, Rene 41 has excellent strength and oxidation resistance at elevated temperatures, making it ideal for high-temperature structural components such as turbine casings, combustion chambers, and high-performance fasteners.