Rene 41 springs are highly specialized components made from a nickel-based superalloy known for exceptional high-temperature strength, oxidation resistance, and stability under extreme mechanical loads. A manufacturer producing Rene 41 springs must have advanced forming capabilities, precision heat-treatment systems, and expertise in handling age-hardening superalloys. The following article details material properties, manufacturing processes, supplier characteristics, quality control methods, and industry applications, providing a comprehensive overview for buyers seeking a reliable Rene 41 springs manufacturer.

What Is Rene 41 Alloy?

Rene 41 is a precipitation-hardened nickel-chromium-cobalt superalloy widely used in extreme heat environments. It retains high strength above 1000°F and offers excellent fatigue resistance. Because of its outstanding heat stability and creep resistance, it is commonly selected for springs operating in engines, turbines, and aerospace hardware.

| Property | Description |

|---|---|

| Alloy Type | Nickel-based precipitation-hardened superalloy |

| Typical Temperature Capability | Up to ~1800°F (≈ 980°C) |

| Key Alloying Elements | Ni, Cr, Co, Mo, Ti, Al |

| Common Forms for Springs | Wire, strip, bar |

Manufacturing Capabilities Required for Rene 41 Springs

Rene 41 is far more difficult to process than common stainless steels or standard nickel alloys. Effective manufacturing requires engineering-level precision from raw material all the way to final testing.

| Capability | Why It Matters |

|---|---|

| High-precision wire forming | The alloy is stiff and work-hardens; coiling requires specialized equipment. |

| Controlled solution & aging heat treatment | Essential for achieving final high-temperature strength. |

| Stress-relief processing | Reduces residual stress that may cause failure in extreme environments. |

| Non-destructive testing (NDT) | Ensures freedom from cracks and micro-defects. |

Types of Rene 41 Springs a Manufacturer Can Supply

Due to the material’s mechanical behavior, manufacturers typically provide multiple types of precision-formed springs.

| Spring Type | Typical Use |

|---|---|

| Compression springs | Engine and turbine assemblies requiring stable load at high temperature |

| Extension springs | High-temperature actuation and tension systems |

| Torsion springs | Rotational mechanisms exposed to extreme heat |

| Wave & flat springs | Compact high-load environments such as aerospace seals |

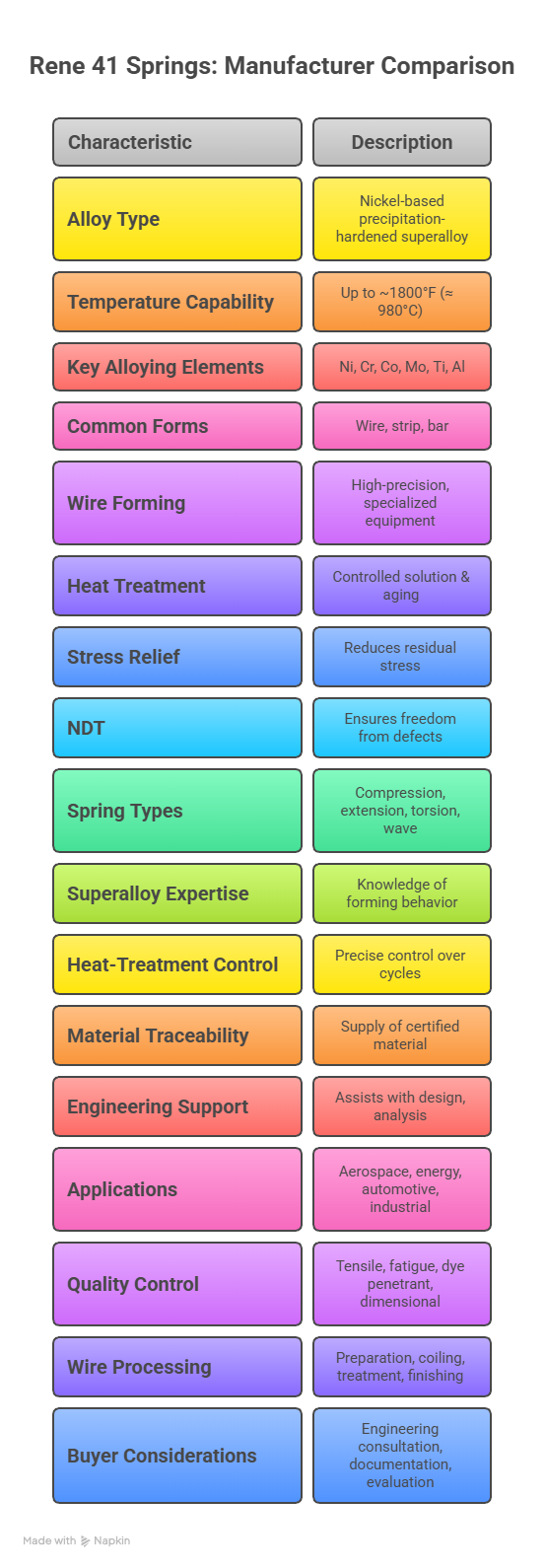

Key Characteristics of a Reliable Rene 41 Springs Manufacturer

Choosing the right manufacturer ensures long-term performance and safety. The best suppliers often have decades of experience with high-temperature nickel alloys.

| Characteristic | Description |

|---|---|

| Expertise in superalloys | Knowledge of forming behavior, aging curves, and metallurgical controls |

| Advanced heat-treatment capability | Precise control over solution and precipitation cycles |

| Material traceability | Supply of certified wire or strip with chemical analysis |

| Custom engineering support | Assists with spring design, load analysis, and failure prevention |

Applications of Rene 41 Springs

Industries that require components to maintain elasticity and load strength under extreme temperatures often rely on Rene 41 springs.

| Industry | Application |

|---|---|

| Aerospace | Jet engines, afterburner assemblies, hot-section mechanisms |

| Energy & Power | Gas turbines, combustion systems |

| Automotive racing | High-temperature engine components |

| Industrial furnaces | Springs operating in constant high-heat environments |

Quality Control Methods Used by Manufacturers

Rene 41 springs undergo strict quality testing due to their use in safety-critical applications.

| Test Method | Purpose |

|---|---|

| Tensile test | Verifies mechanical strength after heat treatment |

| Fatigue test | Ensures performance in cyclic high-stress conditions |

| Dye penetrant or magnetic inspection | Detects surface cracks |

| Dimensional inspection | Ensures tight tolerances for aerospace requirements |

How Manufacturers Process Rene 41 Wire for Springs

Spring production involves several controlled steps to prevent cracking and ensure optimal performance.

| Process Step | Description |

|---|---|

| Wire preparation | Cleaning, tension adjustment, and drawing |

| Coiling | Specialized cold-work forming with precision tools |

| Solution treatment | High-temperature heating to homogenize alloy structure |

| Aging | Precipitation hardening to achieve final strength |

| Final finishing | Shot peening, stress relief, or surface treatment |

Buyer Considerations When Choosing a Rene 41 Springs Manufacturer

To ensure reliability in high-risk environments, buyers should evaluate the following criteria.

| Consideration | Reason |

|---|---|

| Engineering consultation availability | Custom springs require design optimization |

| Heat-treatment documentation | Critical for verifying mechanical properties |

| Sample evaluation capability | Useful for prototype aerospace or turbine testing |

| Lead time and capacity | Superalloy processing requires longer scheduling |

Related Questions

1. What makes Rene 41 suitable for high-temperature springs?

Its precipitation-hardened structure provides exceptional strength, oxidation resistance, and load stability at temperatures approaching 1800°F.

2. Are Rene 41 springs better than Inconel springs?

Rene 41 generally offers higher high-temperature strength than many Inconel grades, making it advantageous for extreme aerospace or turbine environments.

3. What industries commonly use Rene 41 springs?

Aerospace, gas turbine manufacturing, high-temperature industrial systems, and advanced automotive engineering frequently use Rene 41 springs.