Rene 41 strip alloy is a high-performance nickel-based superalloy designed for use in extreme high-temperature and high-stress environments. Known for its excellent oxidation resistance, superior strength, and ability to perform under extreme conditions, this alloy is commonly used in aerospace, power generation, and chemical processing industries. Rene 41 strip is widely used for manufacturing parts like turbine blades, combustion chambers, and other components that require superior mechanical properties. In this article, we will explore the properties, applications, and suppliers of Rene 41 strip alloy.

What is Rene 41 Strip Alloy?

Rene 41 is a nickel-chromium alloy known for its outstanding strength, oxidation, and creep resistance at elevated temperatures. It is engineered for applications where materials are exposed to high temperatures and mechanical stress. Rene 41 strip alloy is manufactured in thin, flat forms, which makes it ideal for precision applications requiring high strength in both the transverse and longitudinal directions. The alloy provides excellent resistance to both thermal and mechanical fatigue, making it ideal for turbine engines, heat exchangers, and other high-temperature applications.

Properties of Rene 41 Strip Alloy

Rene 41 strip alloy has several key properties that make it a preferred material for high-temperature applications:

- High Strength: Rene 41 offers excellent tensile and yield strength, even at high temperatures, ensuring structural integrity in demanding applications.

- Oxidation Resistance: This alloy performs well in high-oxygen environments, maintaining its strength and surface integrity even in oxidizing conditions.

- Creep Resistance: Rene 41 strip resists deformation under long-term stress at elevated temperatures, which is crucial in turbine blades and other critical components.

- Corrosion Resistance: It exhibits resistance to various forms of corrosion, including sulfidation and carburization, making it ideal for chemical processing applications.

- Good Fabricability: Despite its high strength, Rene 41 strip is relatively easy to fabricate and can be cut, welded, and shaped to meet the specific needs of the application.

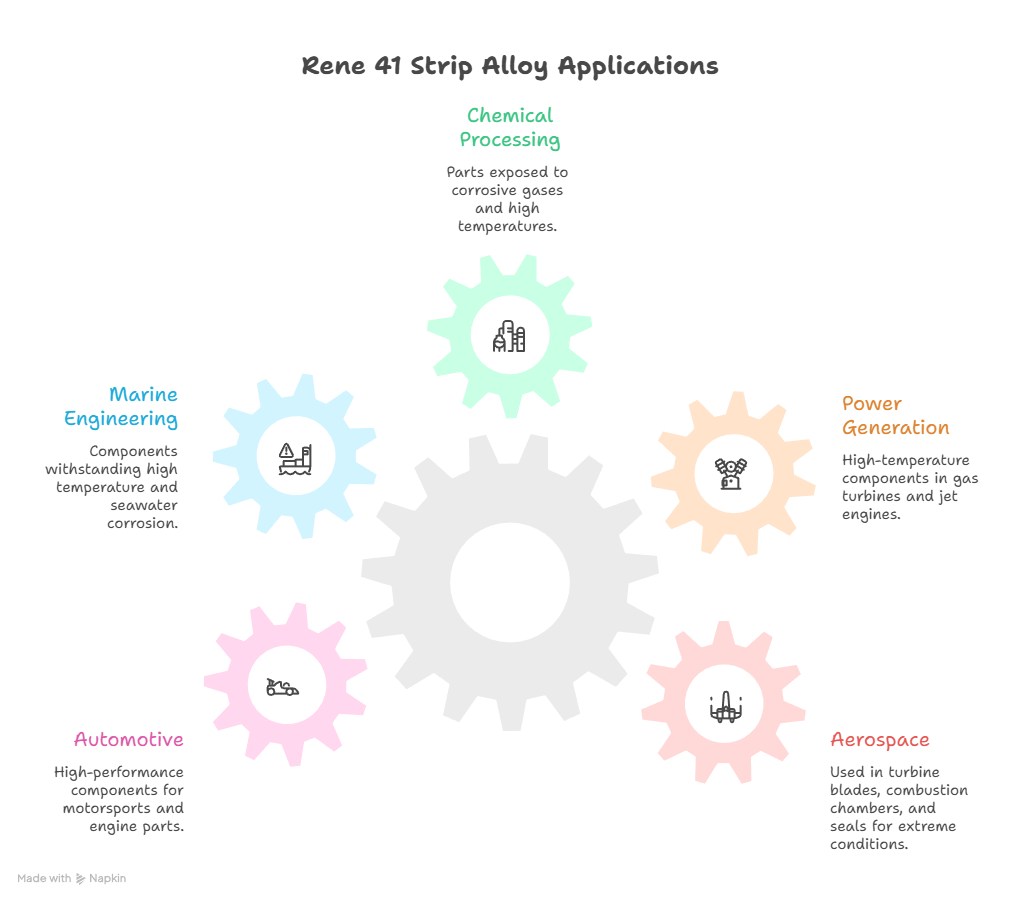

Applications of Rene 41 Strip Alloy

Rene 41 strip alloy is used in a variety of industries, particularly where high strength, oxidation resistance, and ability to withstand high temperatures are required. Some common applications include:

- Aerospace: Used in turbine blades, combustion chambers, seals, and other components exposed to extreme conditions.

- Power Generation: High-temperature components in gas turbines and jet engines.

- Chemical Processing: Parts exposed to corrosive gases, high temperatures, and mechanical stress.

- Marine Engineering: Components that must withstand both high temperature and seawater corrosion.

- Automotive: High-performance components for motorsports and engine parts requiring superior strength and durability.

Rene 41 Strip Alloy Suppliers

When sourcing Rene 41 strip alloy, it is important to find reliable suppliers who offer high-quality material with full certifications. Below are some trusted suppliers of Rene 41 strip alloy:

- Ncalloys: Ncalloys offers a wide range of Rene 41 strip alloys in various sizes and thicknesses. All materials come with full certifications to meet the needs of industries like aerospace, power generation, and chemical processing. For a quote, contact [email protected].

- Special Metals: A well-known manufacturer of high-performance alloys, Special Metals offers Rene 41 strip in different thicknesses and sizes for various high-temperature applications.

- Haynes International: Haynes produces Rene 41 strip alloy, providing excellent quality and reliability for aerospace and power generation industries.

- Rolled Alloys: Rolled Alloys offers Rene 41 strips with quick delivery times and competitive pricing for industries like aerospace, automotive, and power generation.

- Future Metals: A leading supplier of Rene 41 strip alloy, Future Metals offers material traceability, custom cutting services, and fast delivery times.

Why Choose Ncalloys for Rene 41 Strip Alloy?

Ncalloys is a trusted supplier of Rene 41 strip alloy, offering high-quality material for industries requiring exceptional high-temperature performance. Our Rene 41 strip alloys come with full certifications and meet the most stringent industry standards. We provide custom sizes, cutting services, and fast delivery to meet the unique needs of our customers.

Manufacturer: Ncalloys

Contact Email: [email protected]

Related Questions

1. What is the difference between Rene 41 strip alloy and other nickel-based alloys?

Rene 41 has a higher concentration of chromium, providing excellent oxidation resistance at high temperatures, while other nickel alloys may focus on corrosion resistance or weldability. It is specifically designed for high-temperature applications that require superior strength.

2. Can Rene 41 strip alloy be welded?

Yes, Rene 41 strip alloy can be welded using standard welding techniques, but special care must be taken to avoid thermal cracking. Preheating and post-weld heat treatment are often recommended.

3. What are the advantages of using Rene 41 strip alloy in aerospace applications?

Rene 41 strip alloy provides excellent performance in aerospace applications due to its ability to withstand extreme temperatures, oxidation, and mechanical stress, making it ideal for turbine blades, combustion chambers, and other critical engine components.