Rene 41 is a high-performance nickel-chromium-cobalt superalloy known for its exceptional strength at elevated temperatures and excellent oxidation resistance. It is widely used in aerospace, power generation, and high-temperature industrial applications. Suppliers provide Rene 41 in bars, rods, sheets, wires, and tubes suitable for critical applications where durability and heat resistance are essential.

What Is Rene 41?

Rene 41 is a precipitation-hardenable nickel-based superalloy designed for high-strength applications at elevated temperatures. It is commonly used in turbine blades, exhaust valves, high-performance fasteners, and other critical components exposed to extreme heat.

Chemical Composition of Rene 41

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 14–16 |

| Cobalt (Co) | 19–21 |

| Molybdenum (Mo) | 2.2–2.8 |

| Titanium (Ti) | 1.3–1.7 |

| Aluminum (Al) | 1.3–1.7 |

| Iron (Fe) | ≤3 |

| Carbon (C) | ≤0.1 |

| Silicon (Si) | ≤0.5 |

| Manganese (Mn) | ≤0.5 |

Physical and Mechanical Properties

| Property | Value |

|---|---|

| Density | 8.38 g/cm³ |

| Melting Range | 1325–1380°C |

| Tensile Strength | 950–1050 MPa |

| Yield Strength | 700–750 MPa |

| Elongation | 12–18% |

| Hardness | 320–350 HB |

| Maximum Working Temperature | 980°C |

Applications

| Industry | Application |

|---|---|

| Aerospace | Turbine blades, jet engine components |

| Automotive | Exhaust valves, turbocharger parts |

| Power Generation | Gas turbines, combustion chambers |

| Industrial Heating | Furnace components, high-temperature fasteners |

Product Forms Supplied

| Form | Size Range | Typical Application |

|---|---|---|

| Round Bar / Rod | 6–300 mm diameter | Shafts, high-strength fasteners |

| Sheet / Plate | 0.5–50 mm thickness | Combustion chamber liners, structural components |

| Wire / Strip | 0.5–10 mm diameter | Springs, clips, welding wire |

| Pipe / Tube | 6–114 mm OD | High-temperature lines, heat exchangers |

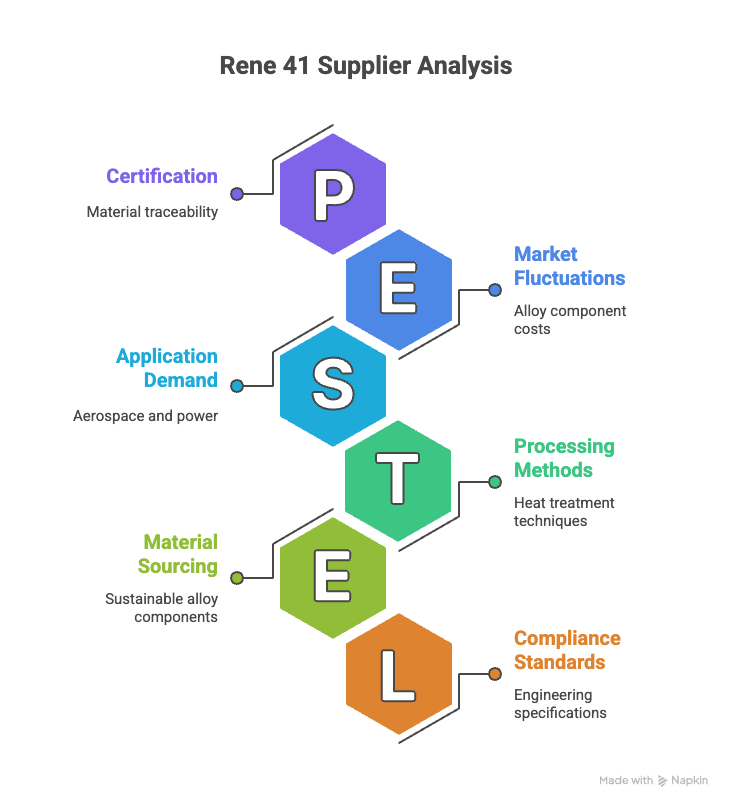

Factors Affecting Price

| Factor | Impact |

|---|---|

| Size / Diameter / Weight | Larger or heavier pieces increase material cost, smaller sizes may require more processing |

| Processing / Finishing | Heat treatment, forging, machining increase cost |

| Certification | Certified material with traceable documentation increases price |

| Quantity / MOQ | Larger orders reduce price per kg |

| Material Market | Fluctuations in nickel, cobalt, and alloy components affect cost |

| Form / Shape | Custom shapes or non-standard forms increase cost |

Choosing a Supplier

When selecting a Rene 41 supplier, ensure:

- Supplier provides a material certificate stating UNS N07041 / W.Nr 2.4973.

- Form (bar, sheet, wire, tube) matches your requirements.

- Heat treatment (solution + age) meets application specifications.

- Surface finish and straightness meet engineering standards.

- Lead time, minimum order quantity, and shipping logistics are suitable.

Pricing Overview

| Form | Approximate Price (USD/kg) |

|---|---|

| Round Bar / Rod | 50–80 |

| Sheet / Plate | 55–85 |

| Wire / Strip | 60–90 |

| Forging Blanks / Special Forms | 40–60 |

Related Questions

1. What forms of Rene 41 are available from suppliers?

Suppliers provide Rene 41 in round bars, rods, sheets, plates, wires, strips, and tubes.

2. What factors affect the price of Rene 41?

Size, form, processing, heat treatment, certification, quantity, and material market conditions affect cost.

3. How to choose a reliable Rene 41 supplier?

Check for certification, material traceability, availability of the required form, heat treatment condition, and supplier reliability in lead time and logistics.