Rene 41 and Inconel alloys are both widely used in high-temperature and high-strength applications, particularly in aerospace, gas turbines, and other extreme environments. Although they are often compared due to their similar service conditions, Rene 41 is a precipitation-hardened nickel-based superalloy designed for exceptional strength at elevated temperatures, while Inconel refers to a family of nickel-chromium alloys optimized for corrosion resistance and thermal stability. Understanding the differences between Rene 41 and various Inconel grades is essential when selecting the right material for demanding engineering applications.

What Is Rene 41?

Rene 41 is a nickel-based precipitation-hardenable superalloy known for its outstanding strength retention at temperatures up to approximately 980°C. It contains nickel, chromium, cobalt, molybdenum, and titanium, which provide excellent creep resistance, fatigue strength, and oxidation resistance. Rene 41 is commonly used in aerospace structural components, turbine parts, and fasteners where high mechanical strength is critical.

What Is Inconel?

Inconel is not a single alloy but a group of nickel-chromium-based superalloys such as Inconel 600, 625, 718, and 601. These alloys are primarily designed to provide excellent corrosion resistance, oxidation resistance, and high-temperature performance. Some grades like Inconel 718 are also precipitation-hardened, while others focus more on environmental resistance than maximum strength.

Chemical Composition Comparison

| Element | Rene 41 | Typical Inconel (e.g., 625/718) |

|---|---|---|

| Nickel (Ni) | Base Element | Base Element |

| Chromium (Cr) | High for oxidation resistance | High for corrosion resistance |

| Cobalt (Co) | Significant content for strength | Usually low or absent |

| Molybdenum (Mo) | Strengthening element | Present in some grades like 625 |

| Titanium/Aluminum | Enables precipitation hardening | Used in age-hardened grades like 718 |

| Iron (Fe) | Low | Varies depending on grade |

Mechanical Property Differences

The biggest distinction between Rene 41 and most Inconel alloys is strength at very high temperatures.

| Property | Rene 41 | Inconel Alloys |

|---|---|---|

| High-Temperature Strength | Extremely high | Moderate to high (grade dependent) |

| Creep Resistance | Excellent for long exposure | Good but often lower than Rene 41 |

| Fatigue Resistance | Outstanding | Very good in alloys like 718 |

| Corrosion Resistance | Good | Typically superior |

| Fabricability | More difficult to process | Easier depending on grade |

Temperature Capability

| Material | Typical Maximum Service Temperature | Best Use Case |

|---|---|---|

| Rene 41 | Up to ~980°C | High-stress aerospace structures |

| Inconel 718 | Up to ~700°C | High-strength fasteners and turbine parts |

| Inconel 625 | Up to ~650°C | Corrosion-resistant environments |

| Inconel 601 | Excellent oxidation to ~1100°C | Thermal processing equipment |

Typical Applications Comparison

| Application | Rene 41 | Inconel |

|---|---|---|

| Aerospace Structural Parts | Widely used | Used depending on grade |

| Gas Turbine Components | High-stress sections | Combustors and casings |

| Fasteners and Bolting | Extreme strength required | Inconel 718 commonly used |

| Chemical Processing | Less common | Inconel 625 preferred |

| Heat-Treat Equipment | Specialized use | Inconel 600/601 widely used |

Manufacturing Considerations

Rene 41 is more difficult to machine and fabricate due to its high strength and work-hardening behavior. It often requires controlled heat treatment and specialized tooling. Inconel alloys, while still challenging compared to stainless steel, are generally easier to form, weld, and machine depending on the specific grade. This difference can influence project cost and manufacturing time.

Cost Comparison

| Factor | Rene 41 | Inconel |

|---|---|---|

| Raw Material Cost | Higher due to cobalt and strengthening elements | Varies widely by grade |

| Processing Cost | High due to difficult fabrication | Moderate to high |

| Availability | More specialized supply | Widely available globally |

| Typical Use | Critical aerospace parts | Broader industrial usage |

Choosing Between Rene 41 and Inconel

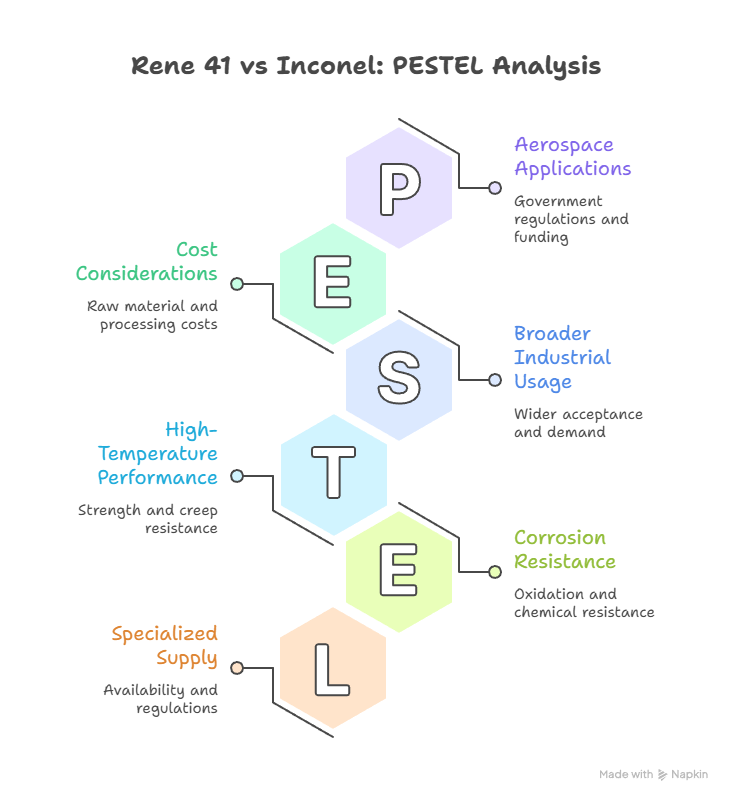

The decision depends on whether the application demands maximum mechanical strength at elevated temperature or superior corrosion resistance and versatility. Rene 41 is typically selected for aerospace-grade structural performance, while Inconel alloys are chosen for balanced resistance to heat, corrosion, and manufacturability across many industries.

Manufacturer: Ncalloys

Contact Email: [email protected]

Related Questions

1. Is Rene 41 stronger than Inconel?

Yes, Rene 41 generally provides higher strength and creep resistance at elevated temperatures, making it ideal for aerospace structural applications.

2. Why is Inconel more widely used than Rene 41?

Inconel alloys offer a better balance of corrosion resistance, availability, and easier fabrication, making them suitable for a broader range of industries.

3. Which is better for high-temperature corrosion environments?

Inconel alloys such as 625 or 601 are usually preferred because they provide superior resistance to oxidation and chemical corrosion.