Rene 41 vs Inconel 718 is one of the most commonly researched comparisons among engineers, buyers, and manufacturers working with high-temperature nickel-based superalloys. Both alloys are widely used in aerospace, gas turbines, and extreme heat environments, but they differ significantly in composition, performance, cost, and machinability. This article provides a large-volume, structured, table-rich explanation to help readers clearly understand how Rene 41 compares with Inconel 718 in mechanical properties, heat resistance, applications, pricing, and fabrication characteristics.

Overview of Rene 41 and Inconel 718

Rene 41 and Inconel 718 are both precipitation-hardened nickel-based superalloys known for their exceptional strength. Rene 41 is typically chosen for extremely high temperatures, while Inconel 718 offers excellent strength with better manufacturability.

| Alloy | Main Features |

| Rene 41 | Superior high-temperature strength; excellent stress-rupture resistance |

| Inconel 718 | High strength + superior workability; widely used industrially |

Chemical Composition Comparison

Chemical composition has a direct influence on alloy performance, temperature capability, and cost. Rene 41 contains more cobalt and chromium, giving it stronger high-temperature strength. Inconel 718 contains significant niobium, improving age-hardening response and forming characteristics.

| Element | Rene 41 (Approx.) | Inconel 718 (Approx.) |

| Nickel | 50–55% | 50–55% |

| Chromium | 18–20% | 17–21% |

| Molybdenum | 9–10% | 2.8–3.3% |

| Niobium | — | 4.75–5.5% |

| Cobalt | 10–12% | — |

| Titanium + Aluminum | 3–4% | ~1–2% |

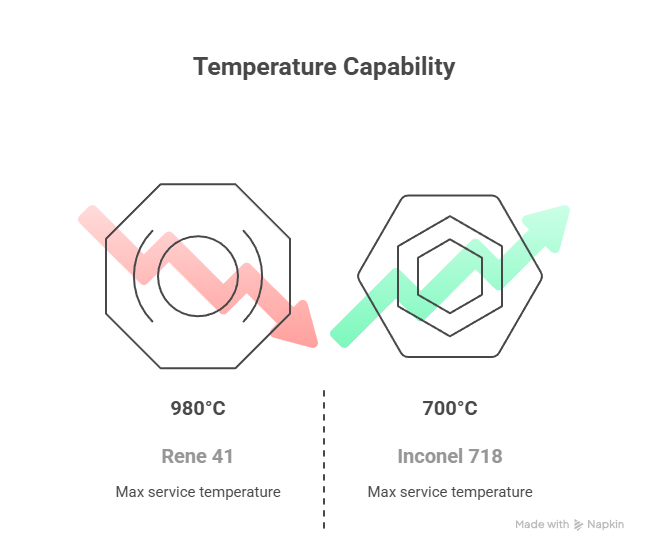

Temperature Capability

One of the most important differences between Rene 41 and Inconel 718 is their usable temperature range. Rene 41 is engineered for extreme hot sections, while Inconel 718 can lose strength above ~700°C.

| Alloy | Recommended Max Service Temp |

| Rene 41 | Up to ~980°C (1800°F) |

| Inconel 718 | Up to ~700°C (1300°F) |

Mechanical Strength Differences

Rene 41 maintains its strength at very high temperatures, making it suitable for turbine blades and hot-section structural components. Inconel 718, while strong at room and moderate high temperatures, softens faster at extreme temperatures.

| Temperature | Rene 41 Strength | Inconel 718 Strength |

| Room Temp | Very High | Very High |

| 700°C | High | Moderate |

| 900°C | Moderate–High | Low |

Applications Comparison

The optimal application depends on required temperature resistance, machinability, and cost. Here is a comparison based on real industry usage.

| Alloy | Main Applications |

| Rene 41 | Turbine blades, jet engine hot-section parts, afterburner components, high-stress bolting |

| Inconel 718 | Fasteners, cryogenic parts, turbine discs, aerospace structural parts, oil & gas components |

Machinability Comparison

In machinability, Inconel 718 is significantly easier to work with. Rene 41 is notoriously difficult to machine, especially in the age-hardened condition, increasing production time and cost.

| Alloy | Machinability Rating |

| Rene 41 | Very Low (hard to machine) |

| Inconel 718 | Moderate (easier compared with most superalloys) |

Price Comparison

Rene 41 is typically more expensive due to its composition and limited production sources. Inconel 718 benefits from larger global manufacturing capacity, making it generally more affordable.

| Alloy | Relative Market Price |

| Rene 41 | Higher |

| Inconel 718 | Moderate |

Weldability Comparison

Inconel 718 is known for good weldability, while Rene 41 requires strict control and is prone to cracking during welding.

| Alloy | Weldability |

| Rene 41 | Difficult; crack-sensitive |

| Inconel 718 | Good; widely welded in industry |

Which Alloy Should You Choose?

Selecting between Rene 41 and Inconel 718 depends on service temperature, cost constraints, and manufacturing requirements. Rene 41 is ideal for extreme heat sections, while Inconel 718 is more cost-effective for medium-temperature high-strength applications.

FAQ: Rene 41 vs Inconel 718

Is Rene 41 stronger than Inconel 718 at high temperatures?

Yes. Rene 41 maintains superior strength above 700°C, while Inconel 718 begins to lose strength significantly at those temperatures.

Which alloy is easier to machine, Rene 41 or Inconel 718?

Inconel 718 is much easier to machine. Rene 41 is extremely difficult to cut, especially in the aged condition.

Is Inconel 718 cheaper than Rene 41?

Yes. Inconel 718 generally costs less due to larger production volumes and easier manufacturability, while Rene 41 has a higher market price.