Seamless nickel alloy tubing is a premium form of tubing manufactured without any welded joints, providing superior strength, uniformity, and corrosion resistance. It is highly demanded in industries where performance in extreme environments is critical, such as chemical processing, oil and gas, marine, power generation, and aerospace. The seamless manufacturing process ensures consistent microstructure, making it more reliable under high pressure and high temperature compared to welded tubing.

Chemical Composition of Common Seamless Nickel Alloys

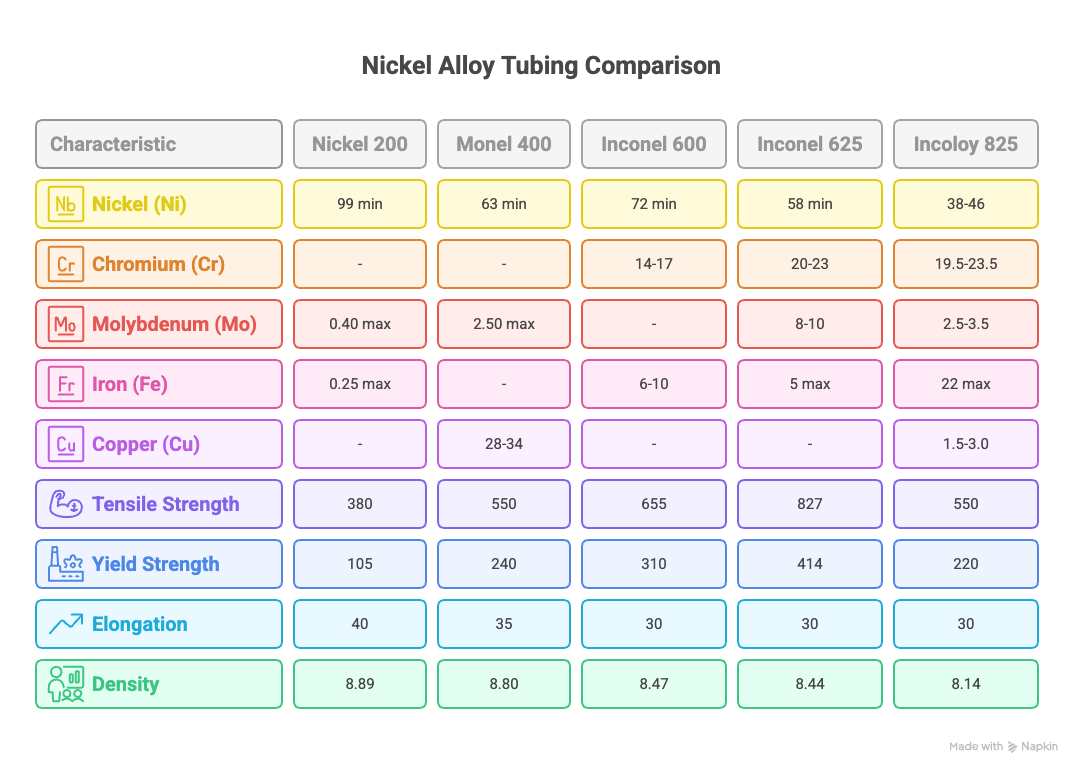

Seamless nickel alloy tubing is produced in various grades, with the most popular being Alloy 200, Alloy 400, Alloy 600, Alloy 625, and Alloy 825. Each grade offers a specific balance of elements for different applications.

| Alloy | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Iron (Fe) | Copper (Cu) |

|---|---|---|---|---|---|

| Nickel 200 | 99 min | – | – | 0.40 max | 0.25 max |

| Monel 400 | 63 min | – | – | 2.50 max | 28-34 |

| Inconel 600 | 72 min | 14-17 | – | 6-10 | – |

| Inconel 625 | 58 min | 20-23 | 8-10 | 5 max | – |

| Incoloy 825 | 38-46 | 19.5-23.5 | 2.5-3.5 | 22 max | 1.5-3.0 |

Mechanical Properties of Seamless Nickel Alloy Tubing

Seamless nickel alloy tubing delivers excellent performance under mechanical stress. The following table shows general mechanical property ranges for common nickel alloys:

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|

| Nickel 200 | 380 | 105 | 40 | 8.89 |

| Monel 400 | 550 | 240 | 35 | 8.80 |

| Inconel 600 | 655 | 310 | 30 | 8.47 |

| Inconel 625 | 827 | 414 | 30 | 8.44 |

| Incoloy 825 | 550 | 220 | 30 | 8.14 |

Advantages of Seamless Nickel Alloy Tubing

Compared with welded tubing, seamless nickel alloy tubing offers unique benefits:

| Feature | Seamless Nickel Alloy Tubing | Welded Nickel Alloy Tubing |

|---|---|---|

| Strength | No weak weld zones, uniform strength | Potential weakness at weld seam |

| Corrosion Resistance | Excellent, continuous grain structure | Good, but welds may corrode faster |

| Pressure Resistance | Superior for high-pressure systems | Lower compared to seamless |

| Dimensional Accuracy | High precision with tight tolerances | Moderate precision |

| Cost | Higher due to complex manufacturing | Lower production cost |

Applications of Seamless Nickel Alloy Tubing

Seamless nickel alloy tubing is used in industries where both corrosion resistance and mechanical strength are vital:

| Industry | Applications |

|---|---|

| Chemical Processing | Heat exchangers, evaporators, condenser coils |

| Oil & Gas | Downhole tubing, subsea piping, refinery units |

| Marine | Seawater systems, desalination plants |

| Aerospace | Hydraulic lines, fuel systems, exhaust components |

| Power Generation | Steam generators, boiler tubing, nuclear reactors |

Factors Affecting Seamless Nickel Alloy Tubing Price

The price of seamless nickel alloy tubing is influenced by:

- Raw material costs of nickel, chromium, and molybdenum

- Grade and alloy composition

- Wall thickness and tubing size

- Production technology and supplier certification

- Global demand in oil, gas, and aerospace industries

Related Questions and Answers

Why choose seamless nickel alloy tubing?

Seamless nickel alloy tubing provides superior strength, pressure resistance, and reliability compared to welded tubing, making it ideal for demanding applications.

Is seamless nickel alloy tubing more expensive than welded?

Yes, seamless tubing is generally more expensive due to its complex manufacturing process, but its long service life often offsets the higher initial cost.

Which industries use seamless nickel alloy tubing most?

It is widely used in chemical plants, oil and gas exploration, marine systems, aerospace equipment, and power generation facilities.