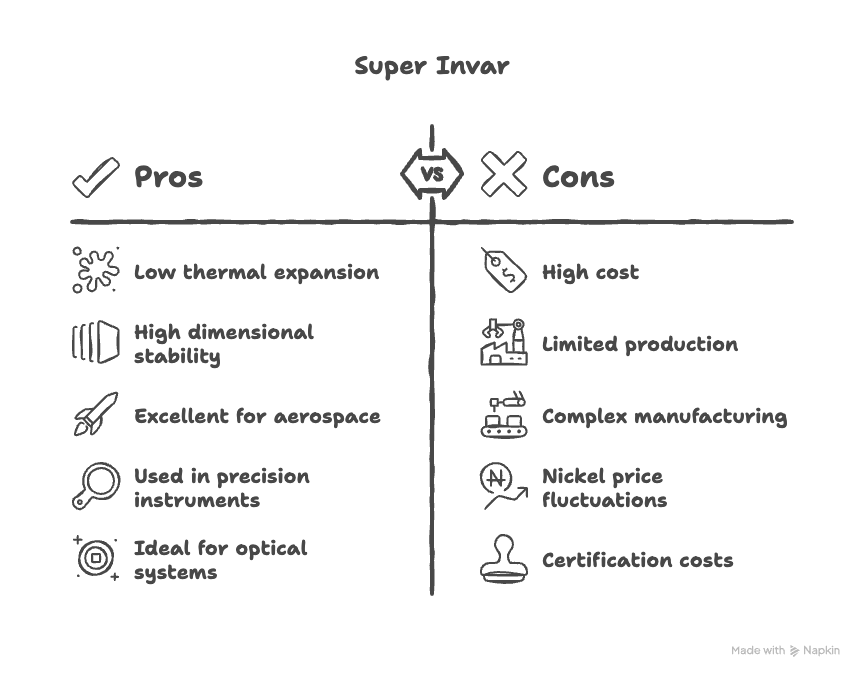

Super Invar is a controlled-expansion nickel-iron alloy known for its extremely low coefficient of thermal expansion and excellent dimensional stability across a specific temperature range. Because of these unique properties, Super Invar is widely used in aerospace, precision instruments, optical systems, semiconductor manufacturing equipment, and cryogenic assemblies. However, its specialized alloy chemistry and limited production capacity make it significantly more expensive than common steel or stainless steel grades. This article breaks down typical Super Invar price ranges, the factors that influence cost, and guidance for estimating material expenses in your project.

Typical Super Invar Price Ranges

Super Invar pricing varies depending on product form, size, specification, surface finish, and order volume. Below is a general overview of typical price ranges in USD per kilogram for common product forms:

| Product Form | Approx. Price (USD/kg) |

|---|---|

| Round Bar / Rod | $50 – $110 |

| Sheet / Plate | $55 – $120 |

| Strip (thin gauge) | $70 – $140 |

| Tube / Pipe | $60 – $130 |

| Precision Machined Parts | $90 – $180+ |

Prices shown above are approximate and represent industrial averages. Actual costs may differ based on supplier, certification level, and quantities ordered.

Price by Product Form and Processing

Different Super Invar product forms command different price points based on manufacturing complexity and material yield:

Round Bar: Often the most commonly stocked form, bars are typically priced moderately because they are produced in larger sizes and cut to order.

Sheet and Plate: Sheets and plates require additional rolling and leveling processes, which can add to the overall price.

Strip: Thin strip stock is more difficult to produce due to tight thickness tolerances, so it tends to be on the higher end of the price spectrum.

Tube or Pipe: Tubing adds fabrication steps such as piercing and drawing, increasing cost compared with solid bar stock.

Precision Machined Parts: Finished components involve cutting, grinding, and sometimes heat treating, which further raise the unit cost.

Key Factors Influencing Super Invar Price

Raw Material Costs: Super Invar contains significant nickel and cobalt content, both of which are relatively expensive base metals. Fluctuations in nickel prices have a direct impact on Super Invar pricing.

Alloying Elements and Chemistry Control: Precise control of alloying elements is required to achieve the ultra-low thermal expansion properties, which increases production cost compared with standard alloys.

Manufacturing Complexity: Super Invar production involves specialized melting, controlled heat treatment, and tight dimensional processes that require skilled operators and more costly equipment.

Certifications and Testing: Material supplied for aerospace, medical, or semiconductor applications often requires specific testing and traceability documentation, which adds to the final price.

Order Quantity: Larger orders typically receive lower unit prices due to economies of scale, while small batch orders or custom sizes can be more expensive per kilogram.

Supplier and Regional Pricing: Material prices can vary by supplier location. Factory pricing from regions with lower production costs may appear cheaper, but total landed cost must account for freight, tariffs, and lead times.

Price Comparison: Super Invar vs Other Alloys

| Material | Approx. Price Level | Performance Focus |

|---|---|---|

| Carbon Steel | Low | General structural use |

| Stainless Steel (e.g., 316) | Moderate | General corrosion resistance |

| Invar 36 | Moderate-High | Low thermal expansion |

| Super Invar 32-5 | High | Ultra-low thermal expansion |

Super Invar is more expensive than standard alloys like stainless steel or Invar 36 due to its specialized properties and production requirements.

Tips for Buying Super Invar Efficiently

• Specify exact material requirements such as product form, dimensions, and surface finish to get accurate quotes.

• Order in larger quantities or standard sizes to benefit from volume pricing.

• Request full material traceability and certifications upfront if needed for aerospace or precision applications.

• Compare quotes from multiple suppliers, but consider delivery times and support services along with price.

How to Get Accurate Super Invar Pricing

To obtain precise pricing, most suppliers will need the following information:

• Product form (bar, sheet, strip, tube, or custom part)

• Dimensions and tolerances

• Required heat treatment or surface finish

• Quantity or total weight

• Certification requirements

Related Questions

Why is Super Invar more expensive than Invar 36?

Super Invar requires tighter control of alloy chemistry and more complex processing to achieve lower thermal expansion, which increases cost.

Does Super Invar price fluctuate with nickel pricing?

Yes, because Super Invar contains a high percentage of nickel, material cost is closely tied to nickel market prices.

Can buying larger quantities reduce Super Invar price?

Yes, bulk orders generally lower the unit price due to economies of scale and reduced overhead per kilogram.