Waspaloy and Inconel are both nickel-based superalloys designed for high-temperature and high-stress environments, commonly used in aerospace, gas turbines, and industrial applications. While both alloys offer excellent strength and corrosion resistance, they differ in composition, mechanical performance, temperature capability, and specific applications. This article provides a detailed comparison between Waspaloy and Inconel.

Comparison Table

| Property | Waspaloy | Inconel 718 |

|---|---|---|

| Primary Composition | Ni 50–60%, Cr 18–21%, Co 12–15%, Mo 3–5%, Ti 1–2%, Al 0.4–1% | Ni 50–55%, Cr 17–21%, Fe balance, Nb 4.75–5.5%, Mo 2.8–3.3%, Ti 0.65–1.15%, Al 0.2–0.8% |

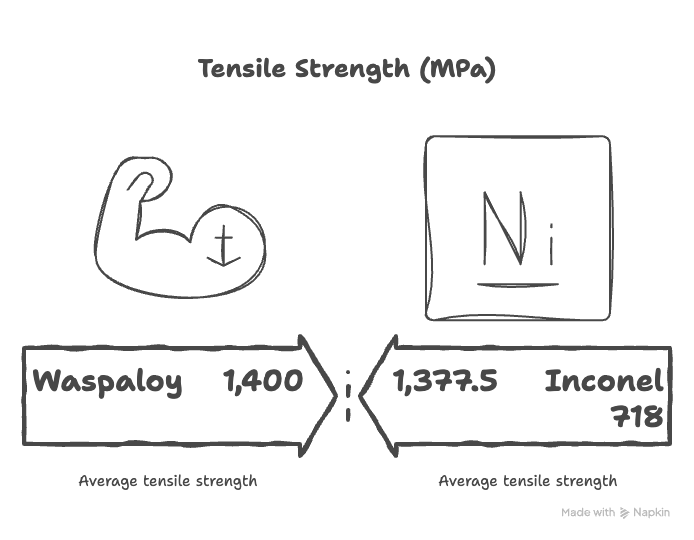

| Tensile Strength | 1,300–1,500 MPa | 1,240–1,515 MPa |

| Yield Strength | 950–1,100 MPa | 1,035–1,240 MPa |

| Elongation | 10–20% | 12–20% |

| High-Temperature Performance | Up to 700–750°C | Up to 700°C |

| Corrosion Resistance | Good (oxidation, hot corrosion) | Excellent (oxidation, moderate corrosion resistance in acidic environments) |

| Weldability | Moderate; requires post-weld heat treatment | Good; easier to weld with proper procedures |

| Applications | Aerospace engines, gas turbines, high-temperature structural components | Aerospace engine components, turbine discs, shafts, valves |

Key Differences

1. Composition: Waspaloy contains higher cobalt content, enhancing high-temperature strength, while Inconel 718 contains niobium and iron for precipitation hardening and moderate corrosion resistance.

2. Temperature Capability: Waspaloy maintains slightly better strength at extreme temperatures (above 700°C), whereas Inconel 718 is optimized for a balance of weldability, corrosion resistance, and mechanical strength up to 700°C.

3. Applications Focus: Waspaloy is used in components where maximum high-temperature strength is critical, while Inconel 718 is more versatile for aerospace and industrial components requiring weldability and toughness.

Related Questions

Which alloy has higher high-temperature strength? Waspaloy generally has slightly higher strength above 700°C compared to Inconel 718.

Which alloy is easier to weld? Inconel 718 is easier to weld, whereas Waspaloy requires post-weld heat treatment to restore properties.

Which alloy is better for corrosion resistance? Inconel 718 typically offers better general corrosion resistance, while Waspaloy is optimized for high-temperature oxidation and hot corrosion resistance.