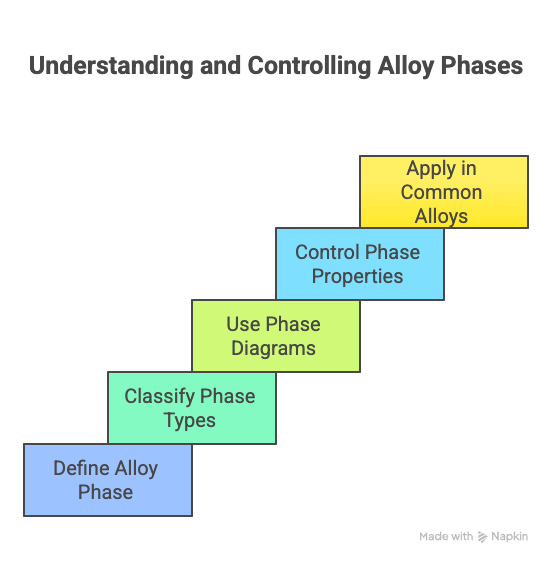

An alloy phase refers to a distinct, physically and chemically uniform portion of a metallic alloy with specific properties and structure. In metallurgy, understanding alloy phases is critical because they determine the mechanical, thermal, and chemical behavior of the material. The phases present in an alloy affect hardness, ductility, corrosion resistance, and heat treatment response, which makes phase knowledge essential for engineers, designers, and metallurgists.

Definition of Alloy Phase

An alloy phase is a region within a metallic system that has uniform composition and structure. Each phase can be a solid solution, an intermetallic compound, or sometimes a liquid phase in molten alloys. Phases are identified by their distinct crystal structure, chemical composition, and physical properties. In a single alloy, multiple phases may coexist, forming what is called a multiphase alloy.

Types of Alloy Phases

Alloy phases can generally be classified into several categories:

1. Solid Solution Phases: A solid solution is a phase where one element is dissolved into the crystal lattice of another. There are two main types:

– Substitutional Solid Solution: Atoms of the solute replace atoms of the solvent in the lattice.

– Interstitial Solid Solution: Smaller atoms fit into the interstitial spaces of the solvent lattice.

2. Intermetallic Phases: These are compounds formed between two or more metals with specific stoichiometry and ordered crystal structure. Intermetallic phases are usually hard and brittle but can improve high-temperature strength.

3. Eutectic Phases: In alloys that solidify from a melt, eutectic phases form at a specific composition and temperature where two or more solid phases grow simultaneously from the liquid, creating a fine microstructure that can enhance mechanical properties.

4. Martensitic and Other Transformation Phases: Certain alloys, like steels, can form martensite or bainite through rapid cooling. These phases result from diffusionless transformations and significantly influence hardness and strength.

Phase Diagrams

Phase diagrams are graphical representations that show which phases are stable at different temperatures, compositions, and sometimes pressures. They are essential tools in metallurgy for predicting alloy behavior. Common diagrams include:

– Binary phase diagrams (two elements)

– Ternary phase diagrams (three elements)

– Isothermal and temperature-composition diagrams

Using phase diagrams, engineers can determine solidification sequences, solubility limits, and heat treatment strategies.

Importance of Alloy Phases

The phases present in an alloy determine its properties:

– Mechanical Properties: Hardness, tensile strength, and ductility are highly dependent on the microstructure and phases.

– Corrosion Resistance: Certain phases are more susceptible to corrosion; controlling phase distribution improves longevity.

– Heat Treatment Response: Knowledge of phases allows precise control of annealing, quenching, and tempering processes to achieve desired properties.

– Wear and Fatigue Resistance: Phases like carbides or intermetallics increase wear resistance and high-cycle fatigue strength.

How Phases Are Controlled

Alloy phases are controlled through:

– Composition Adjustment: Changing the percentage of elements in an alloy shifts the types and amounts of phases.

– Thermal Treatments: Heating and cooling rates influence phase transformations, allowing engineers to refine microstructure.

– Mechanical Processing: Work hardening, rolling, and forging can alter phase morphology and distribution.

Examples of Alloy Phases in Common Alloys

– Steel: Ferrite, pearlite, austenite, martensite, bainite

– Aluminum Alloys: Alpha phase (Al-rich), beta phase (Mg2Si), intermetallics like AlCu

– Nickel Alloys: Gamma prime (Ni3(Al,Ti)) in superalloys, carbide phases (MC, M23C6)

Related Questions

What is a solid solution in alloys?

A solid solution is a single-phase alloy where solute atoms are uniformly distributed in the solvent lattice, either substitutionally or interstitially.

Why are alloy phases important?

Alloy phases determine mechanical strength, ductility, corrosion resistance, and heat treatment behavior, making them crucial for designing reliable materials.

How can alloy phases be changed?

Alloy phases can be controlled by adjusting composition, performing heat treatments, and applying mechanical processes such as rolling or forging to modify microstructure.