Inconel is a high-performance family of nickel-chromium superalloys engineered for exceptional resistance to heat, corrosion, pressure, and mechanical stress. Because Inconel maintains strength at temperatures where most metals fail, it is widely used in aerospace turbines, chemical processing, energy systems, marine equipment, and high-temperature industrial environments. This expanded guide explains what Inconel is, its chemical makeup, major properties, advantages, common grades, industrial applications, and how it compares with stainless steel and other superalloys.

What Is Inconel Made Of

Inconel superalloys are primarily composed of nickel and chromium, with additional strengthening elements such as molybdenum, niobium, iron, titanium, and aluminum. The high nickel content provides unparalleled corrosion resistance, while chromium enhances oxidation resistance at extreme temperatures.

| Element | Typical Range |

| Nickel (Ni) | 50% – 72% |

| Chromium (Cr) | 14% – 23% |

| Iron (Fe) | 3% – 10% |

| Molybdenum (Mo) | 1% – 9% |

| Niobium/Tantalum | 0.5% – 5% |

| Titanium/Aluminum | 0.2% – 3% |

Key Properties of Inconel

Inconel is engineered for environments involving extreme heat, aggressive chemicals, and long-term stress. Its properties make it far more durable than standard stainless steels or common industrial alloys.

| Property | Description |

| High-Temperature Strength | Maintains strength above 1000°C without significant deformation |

| Corrosion Resistance | Resistant to acids, alkalis, seawater, and oxidizing environments |

| Oxidation Resistance | Forms a stable oxide layer that protects against high-heat damage |

| Fatigue Resistance | Performs well under cyclic thermal and mechanical loading |

| Stress-Corrosion Cracking Resistance | Stable under extreme pressure, vibration, and high-temperature stress |

Common Inconel Grades

Different industries rely on specific Inconel grades depending on temperature limits, corrosion exposure, and mechanical requirements. Below are the most widely used grades and their performance characteristics.

| Grade | Main Characteristics |

| Inconel 600 | General purpose; good heat and corrosion resistance |

| Inconel 625 | Excellent seawater and chemical corrosion resistance |

| Inconel 718 | High strength; precipitation-hardening alloy used in aerospace |

| Inconel 601 | Outstanding oxidation resistance in furnace atmospheres |

| Inconel X-750 | Ideal for high-temperature springs and turbine components |

How Inconel Performs in High Temperatures

Inconel’s most important benefit is its ability to maintain excellent mechanical strength at extreme temperatures. While most metals weaken rapidly above 700°C, Inconel remains stable even beyond 1000°C and forms a protective oxide layer that prevents scaling and surface degradation.

| Material | Continuous Use Temperature |

| Inconel Alloys | Up to 1000°C+ |

| Stainless Steel | 600°C – 750°C |

| Titanium | 500°C – 600°C |

| Aluminum | 150°C – 200°C |

Inconel Applications Across Industries

Because Inconel tolerates harsh operating conditions, it is used in critical systems where failure is not acceptable. Industries rely on Inconel for components exposed to heat, pressure, seawater, acids, and extreme wear.

| Industry | Application Examples |

| Aerospace | Turbine blades, exhaust systems, jet engine parts |

| Chemical Processing | Reactors, heat exchangers, vaporizer tubes |

| Oil & Gas | Downhole tools, valves, sour-gas components |

| Marine Engineering | Seawater pumps, propeller shafts, fasteners |

| Power Generation | Nuclear reactor components, gas turbine parts |

Inconel vs Stainless Steel

Many buyers compare Inconel to stainless steel. While stainless steel is more affordable, Inconel offers clearly superior performance in extreme environments.

| Feature | Inconel | Stainless Steel |

| Heat Resistance | Up to 1000°C+ | Up to ~700°C |

| Corrosion Resistance | Exceptional | Moderate to high |

| Seawater Resistance | Excellent | Limited (prone to pitting) |

| Mechanical Strength | Consistent at high temperatures | Drops significantly at high heat |

| Cost | Higher | More affordable |

Why Inconel Is More Expensive

Inconel is considered a premium engineering material due to its nickel-rich composition, difficult manufacturing process, and high demand in precision industries such as aerospace and energy. Although its upfront cost is higher, its long lifespan often reduces long-term maintenance costs.

| Cost Factor | Explanation |

| High Nickel Content | Nickel prices significantly influence overall cost |

| Complex Production | Requires controlled melting and advanced forming techniques |

| Critical Applications | Used where reliability and safety cannot be compromised |

| Longevity | Long service life reduces replacement frequency |

Inconel Compared with Other Superalloys

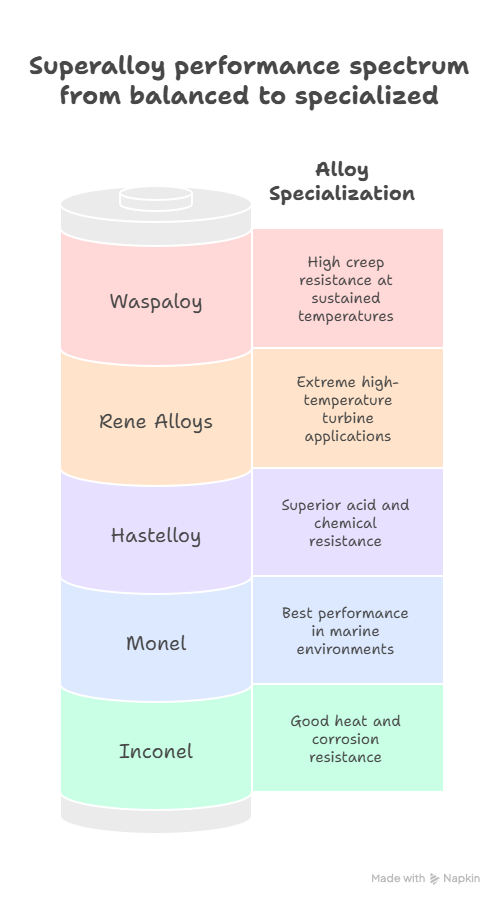

Inconel sits alongside other premium superalloys like Hastelloy, Monel, Rene alloys, and Waspaloy. Each alloy offers unique advantages, but Inconel is often preferred for balanced performance and availability.

| Alloy | Main Advantage |

| Inconel | Balanced heat and corrosion resistance |

| Hastelloy | Superior acid and chemical resistance |

| Monel | Best performance in seawater and marine environments |

| Rene Alloys | Extreme high-temperature turbine applications |

| Waspaloy | High creep resistance at sustained temperatures |

FAQs

What is Inconel used for?

Inconel is used in aerospace turbines, chemical processing plants, oil-and-gas tools, marine equipment, and high-temperature industrial systems.

Is Inconel stronger than stainless steel?

Yes. Inconel maintains high strength at temperatures far above stainless steel limits and provides better corrosion and oxidation resistance.

Why is Inconel so expensive?

Its high nickel content, complex production process, and use in safety-critical industries make Inconel more expensive than standard stainless steels.