Inconel is a family of nickel-chromium-based superalloys renowned for exceptional strength, oxidation resistance, and corrosion resistance at high temperatures. These properties make Inconel an ideal material for industries and applications where extreme heat, corrosive environments, and mechanical stress are common. Understanding its primary uses helps engineers, designers, and procurement specialists select the right alloy for demanding conditions.

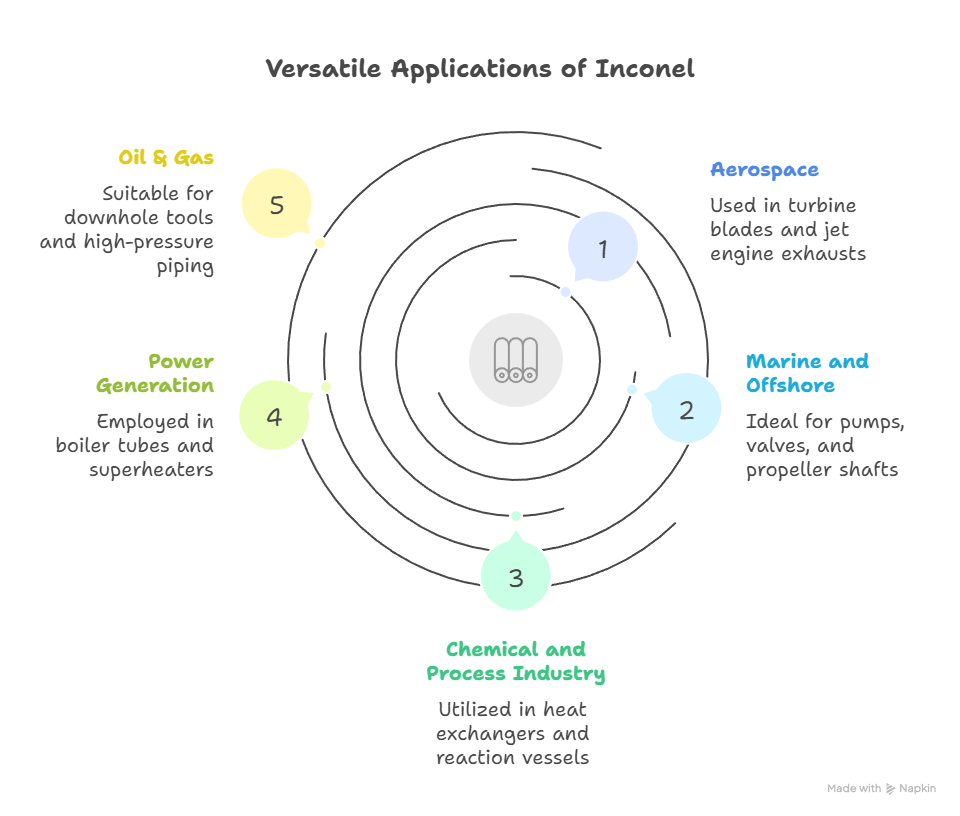

Aerospace Applications

Inconel alloys are widely used in the aerospace industry due to their ability to maintain strength at elevated temperatures and resist oxidation.

| Component | Common Inconel Alloy | Reason for Use |

|---|---|---|

| Turbine Blades | Inconel 718, Inconel 625 | High-temperature strength and creep resistance |

| Jet Engine Exhaust | Inconel 625 | Oxidation resistance at very high temperatures |

| Fasteners & Springs | Inconel 718 | Maintains mechanical integrity under cyclic loads |

Marine and Offshore Applications

Inconel’s excellent corrosion resistance makes it ideal for seawater and salt spray environments.

| Component | Inconel Alloy | Reason for Use |

|---|---|---|

| Pumps & Valves | Inconel 625 | Superior resistance to seawater corrosion |

| Propeller Shafts | Inconel 625 | Durable in chloride-rich environments |

| Flexible Risers | Inconel 625 | Handles both pressure and corrosion |

Chemical and Process Industry

Inconel is widely used for chemical processing equipment due to its resistance to acids, oxidizing agents, and high temperatures.

| Equipment | Inconel Alloy | Reason for Use |

|---|---|---|

| Heat Exchangers | Inconel 625 | Excellent thermal stability and corrosion resistance |

| Reaction Vessels | Inconel 718 | High strength under stress and heat |

| Piping Systems | Inconel 625 | Resistant to acidic and chloride environments |

Power Generation

Inconel alloys are used in power plants where components face extreme heat, pressure, and corrosive gases.

| Component | Inconel Alloy | Reason for Use |

|---|---|---|

| Boiler Tubes | Inconel 625 | Oxidation and high-temperature strength |

| Superheaters | Inconel 718 | Creep resistance at elevated temperatures |

| Turbine Components | Inconel 718 | Maintains mechanical properties under cyclic stress |

Oil & Gas Applications

Inconel is ideal for extreme environments in oil and gas extraction.

| Component | Inconel Alloy | Reason for Use |

|---|---|---|

| Downhole Tools | Inconel 718 | High strength and fatigue resistance |

| High-Pressure Piping | Inconel 625 | Corrosion resistance in aggressive fluids |

| Valves | Inconel 625 | Durable in saltwater and chemical environments |

Related Questions

1. Can Inconel withstand high temperatures?

Yes, Inconel alloys can maintain mechanical strength and resist oxidation at temperatures up to around 1100°C depending on the grade.

2. Is Inconel resistant to corrosion?

Yes, Inconel offers excellent corrosion resistance in seawater, acids, and oxidizing environments, making it suitable for marine and chemical applications.

3. Which industries commonly use Inconel?

Aerospace, marine, chemical processing, power generation, and oil & gas industries commonly use Inconel for components exposed to extreme heat, stress, or corrosive conditions.