Monel is a family of nickel-copper alloys known for exceptional corrosion resistance, high strength, and durability in demanding environments. These alloys perform extremely well in seawater, acidic media, and high-temperature conditions, which is why Monel is widely used in marine engineering, chemical processing, aerospace, and oil & gas industries. Understanding the composition and properties of Monel helps engineers and buyers choose the right grade for their applications.

What Is Monel Alloy?

Monel refers to a group of nickel-copper alloys primarily composed of nickel (around 65–70%) and copper (20–29%), with small additions of iron, manganese, carbon, and silicon. These alloys are known for their excellent resistance to corrosion, especially in seawater and alkaline environments. The most common grades are Monel 400 and Monel K-500, each offering specific performance advantages.

Chemical Composition of Monel Alloys

The composition varies slightly between grades, but the typical Monel chemistry is dominated by nickel and copper. Below is a general reference table:

| Element | Typical Content (%) |

|---|---|

| Nickel (Ni) | 63–70 |

| Copper (Cu) | 20–29 |

| Iron (Fe) | 1–2.5 |

| Manganese (Mn) | 0.3–2 |

| Silicon (Si) | 0.3–0.5 |

| Carbon (C) | 0.3 max |

This combination gives Monel a unique balance of mechanical stability and corrosion resistance, making it reliable in extreme working conditions.

Main Properties of Monel Alloys

Monel alloys possess multiple performance advantages that make them stand out among nickel-based materials. Below are the most important characteristics engineers rely on.

Corrosion Resistance

One of the most defining properties of Monel is its outstanding corrosion resistance. It resists seawater corrosion exceptionally well, including pitting, stress corrosion cracking, and erosion. This feature makes Monel ideal for marine hardware, shipbuilding, propeller shafts, seawater valves, and desalination equipment.

Mechanical Strength

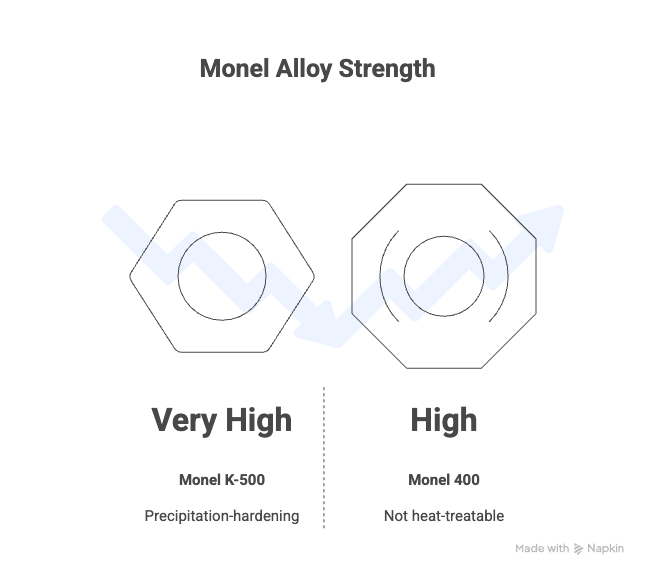

Monel exhibits high tensile strength and toughness across a wide temperature range. Monel K-500, in particular, offers significantly greater strength due to precipitation hardening. This makes the alloy useful for high-load components such as fasteners, pump shafts, valves, and downhole tools.

Heat Resistance

Monel maintains stability and mechanical performance even at elevated temperatures. It works well in both high-temperature steam and certain heating environments where oxidation resistance is essential.

Good Weldability and Formability

Monel alloys can be welded using standard welding processes, including TIG and MIG. They are also easy to form, machine, and fabricate into sheet, plate, bar, tube, and wire, making them versatile for industrial applications.

Non-magnetic Nature

Monel remains essentially non-magnetic, even at lower temperatures. This property is valuable in precision instruments, sensors, and defense-related applications where magnetic interference must be minimized.

Monel 400 vs Monel K-500

Monel 400 is the most widely used grade and offers a balanced combination of corrosion resistance and mechanical properties. Monel K-500 enhances these advantages by adding aluminum and titanium for precipitation hardening, resulting in higher strength while maintaining similar corrosion resistance. This makes K-500 ideal for demanding applications requiring superior load-bearing capability.

| Property | Monel 400 | Monel K-500 |

|---|---|---|

| Strength | High | Very High |

| Corrosion Resistance | Excellent | Excellent |

| Heat Resistance | Good | Improved |

| Hardening Ability | Not heat-treatable | Precipitation-hardening |

| Typical Uses | Marine parts, pumps, heat exchangers | Fasteners, shafts, downhole tools |

Applications of Monel Alloys

Because of its robust properties, Monel finds widespread use across industries that demand reliability and durability under harsh conditions. Key applications include:

Marine & Offshore: Pump shafts, seawater valves, propeller shafts, desalination systems

Chemical Processing: Heat exchangers, reactor vessels, piping systems, chemical tanks

Aerospace: Fasteners, springs, turbine components

Oil & Gas: Downhole equipment, tools, valve components

Electrical & Instrumentation: Sensors, precision components, non-magnetic parts

Workability and Fabrication

Monel is relatively easy to fabricate compared to other high-nickel alloys. It can be hot-worked, cold-worked, and welded using standard nickel-alloy welding techniques. Proper annealing ensures improved ductility and machinability during manufacturing.

Why Engineers Choose Monel

Engineers select Monel when long-term performance is required in corrosive, high-temperature, or high-load environments. Its nickel-copper chemistry offers reliability that many stainless steels cannot match, especially in seawater and strong alkaline environments.

Related Questions

Is Monel stronger than stainless steel?

Yes, Monel generally offers higher strength than many stainless steels, especially in the case of Monel K-500, which is precipitation-hardened for extra mechanical strength.

What is Monel used for?

Monel is widely used in marine engineering, chemical processing equipment, aerospace components, electrical instruments, pumps, valves, and offshore structures due to its corrosion resistance and durability.

Is Monel magnetic?

Monel alloys are typically non-magnetic, even at low temperatures, making them suitable for instrumentation and environments requiring low magnetic permeability.